Pipe-cladded wood protective cushion block

A technology of protective pads and pads, which is applied in the field of pads, can solve the problems of steel plate surface damage, grass handles with low pressure, and low pressure, and achieve the effects of cost reduction, non-damage, and injury prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

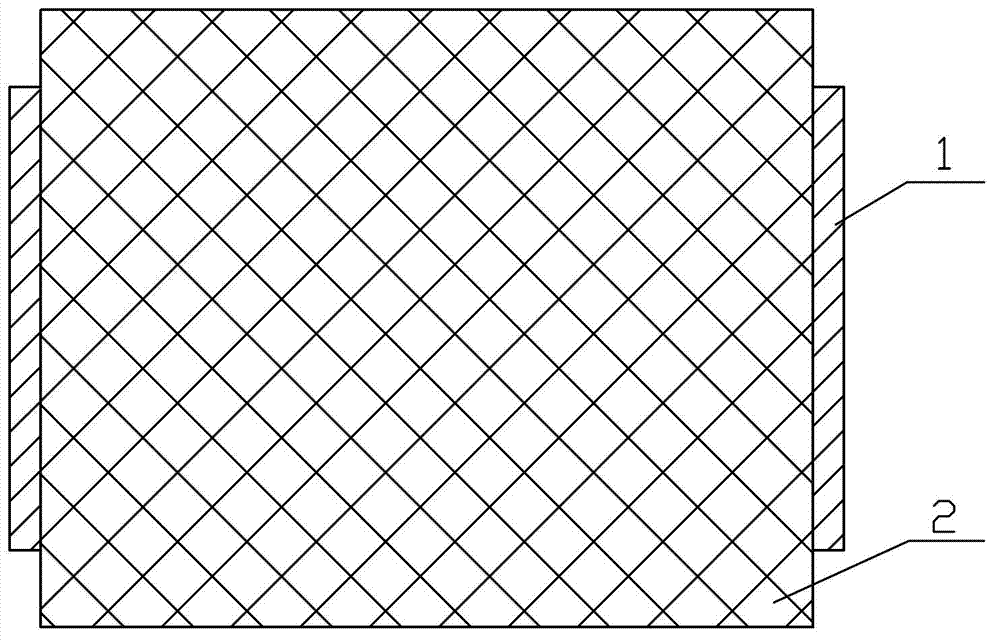

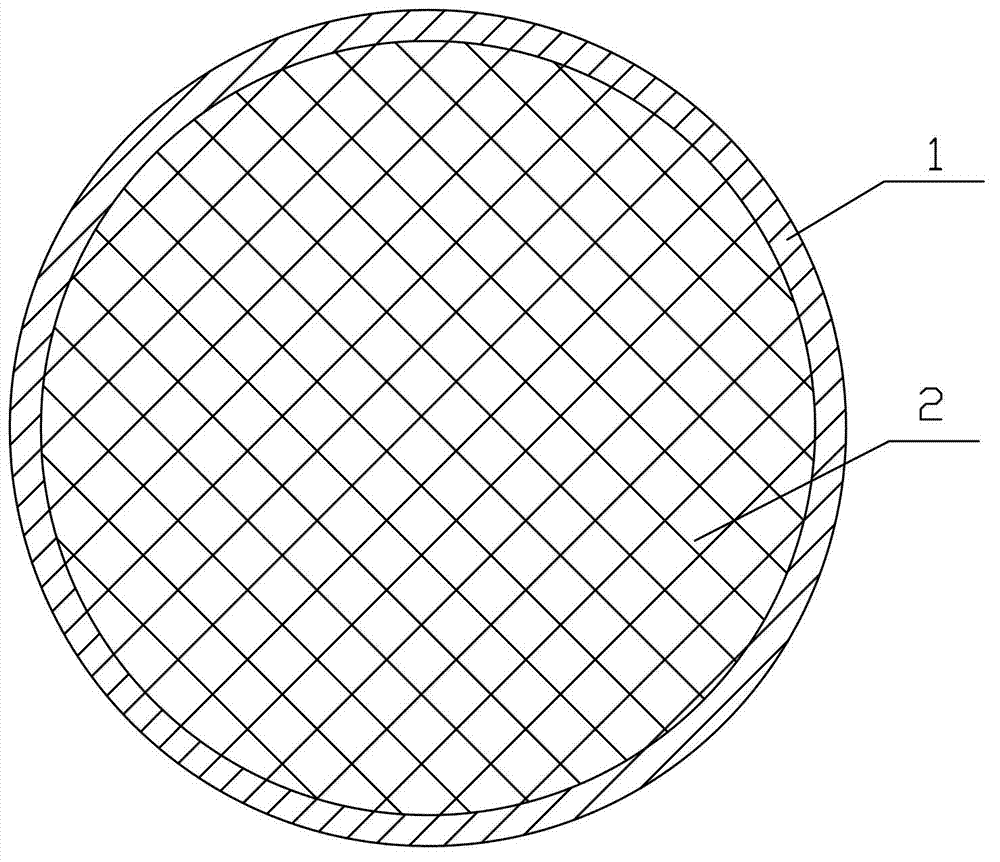

[0012] Refer to the attached figure 1 And attached figure 2 The tube-wrapped wood protective pad of the present invention is described in detail below.

[0013] The tube-wrapped wood protection block of the present invention has a structure comprising a block body 1, the block body 1 is a cylindrical seamless steel pipe, and a cylindrical wooden block 2 is arranged inside the block body 1, and the cylindrical block body 1 is The wooden block 2 fits closely within the inner diameter of the spacer body 1 , and the upper and lower parts of the cylindrical wood block 2 protrude out of the spacer body 1 respectively.

[0014] The upper and lower parts of the cylindrical wooden block 2 protrude 10mm outside the block body respectively.

[0015] The block body 1 is a galvanized steel pipe with a wall thickness of 4 mm, an inner diameter of 100 mm, and a height of 60 mm. The cylindrical wooden block 2 has a diameter of 100 mm and a height of 80 mm.

[0016] The cylindrical block 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com