White ultra-long afterglow luminescent material and preparation method thereof

A luminescent material and ultra-long technology, applied in the field of materials, can solve problems such as limited use, blackening, and insufficient afterglow time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

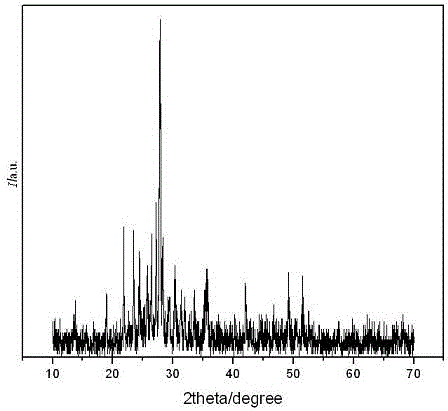

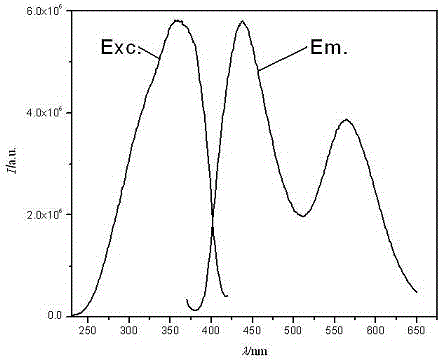

Image

Examples

Embodiment 1

[0057] A white ultra-long afterglow luminescent material, the general formula of the luminescent material is expressed as (M, M*O) 1-x-y · (EuO) x · (MnO) y · aAl 2 o 3 · bSiO2 2 (1), wherein M is Ca, M* is Mg, a=1.0, b=1.0, x=0.05, y=0.4.

[0058] The preparation method is as follows:

[0059] Weigh raw material powder: CaCO 3 0.35mol, (MgCO 3 ) 4 Mg(OH) 2 . 5H 2 O 0.2mol, Eu 2 o 3 0.05mol, MnCO 3 0.4mol, Al2O 3 Micropowder 1mol, SiO 2 Fine powder 1mol. The boric acid consumption is 3.5% of raw material powder gross weight. Al by planetary ball mill 2 o 3 , SiO 2 、Eu 2 o 3 Perform ball milling to a particle size of about 2 microns, and then mix the obtained oxide powder with CaCO 3 , (MgCO 3 ) 4 Mg(OH) 2 . 5H 2 O. MnCO 3 and boric acid for full ball milling, using a metal mold in a two-way molding method to 1000kg / cm 2 Press the green body into a green body with a diameter of 13mm, then put the green body into a corundum crucible, us...

Embodiment 2

[0061] A white ultra-long afterglow luminescent material, the general formula of the luminescent material is expressed as (M, M*O) 1-x-y · (EuO) x · (MnO) y · aAl 2 o 3 · bSiO2 2 (1), wherein M is Ca, M* is Ba, a=1.0, b=2.0, x=0.05, y=0.2.

[0062] The preparation method is as follows:

[0063] Weigh raw material powder: CaCO 3 0.35mol, BaCO 3 0.4mol, Eu 2 o 3 0.05mol, MnCO 3 0.2mol, Al2O 3 Micropowder 1mol, SiO 2 Fine powder 2mol. Boric acid consumption is 4% of raw material powder gross weight. Al by planetary ball mill 2 o 3 , SiO 2 、Eu 2 o 3 Perform ball milling to a particle size of about 3 microns, and then mix the obtained oxide powder with CaCO 3 、BaCO 3 , MnCO 3 and boric acid for full ball milling, using a metal mold in a two-way molding method to 2000kg / cm 2 pressed into a green body with a diameter of 13mm, and then put the green body into a corundum crucible, and use a high-temperature resistance furnace to heat it to 1000°C at...

Embodiment 3

[0065] A white ultra-long afterglow luminescent material, the general formula of the luminescent material is expressed as (M, M*O) 1-x-y · (EuO) x · (MnO) y · aAl 2 o 3 · bSiO2 2 (1), wherein M is Sr, M* is Zn, a=1.0, b=0.5, x=0.005, y=0.2.

[0066] The preparation method is as follows:

[0067] Weigh raw material powder: SrCO 3 0.395mol, ZnCO 3 0.4mol, Eu 2 o 3 0.005mol, MnCO 3 0.2mol, Al2O 3 Micropowder 1mol, SiO 2 Fine powder 0.5mol. The boric acid consumption is 3% of raw material powder gross weight. Al by planetary ball mill 2 o 3 , SiO 2 、Eu 2 o 3 Perform ball milling to a particle size of about 5 microns, and then mix the obtained oxide powder with SrCO 3 , ZnCO 3 , MnCO 3 and boric acid for full ball milling, using a metal mold in a two-way molding method to 2500kg / cm 2 Press the green body into a green body with a diameter of 13mm, and then put the green body into a corundum crucible, use a high-temperature resistance furnace, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com