Multi-station output mechanism

An output mechanism, multi-station technology, applied in mechanical equipment, portable lifting devices, components with teeth, etc., can solve problems such as inability to achieve output separately, affecting work efficiency, and different

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

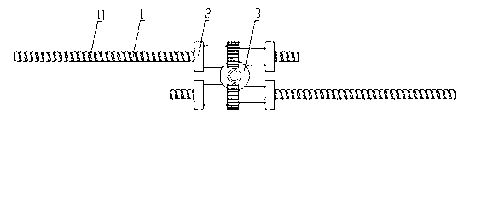

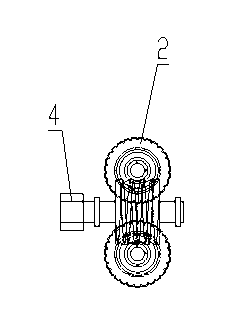

[0017] Such as figure 1 , figure 2 As shown, a multi-station output mechanism includes a turbine shaft 1, a turbine 2, and a worm 3; the turbine shaft 1 is provided with a transmission thread 11, and the transmission thread 11 in this embodiment is a trapezoidal transmission thread 11, through the trapezoidal transmission Thread 11 pulleys or gears obtain different transmission ratios. The middle part of the turbine shaft 1 is connected with a turbine 2. In this embodiment, the middle part of the turbine shaft 1 is provided with splines, and the turbine shaft 1 is connected to the turbine shaft through the splines. 2 connection, the number of the turbine shaft 1 is one or more than one, for the convenience of understanding the present invention, the number of the turbine shaft 1 adopted in this embodiment is two, so as to output the work of four different positions, the turbine shaft 2 It is in transmission connection with the worm 3 , and the worm 3 is connected with the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com