Deep groove double-arm excavator

A technology for excavators and deep trenches, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., and can solve the problem of small excavation depth of ordinary excavators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

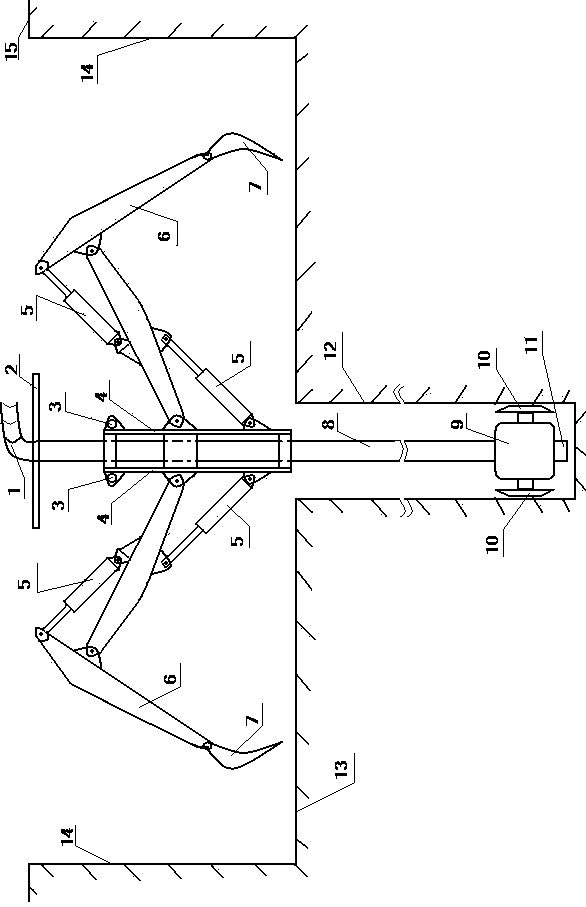

[0011] Accompanying drawing is a kind of concrete embodiment of the present invention, and the upper end of this embodiment square pipe 8 is connected with bend pipe 1, and the lower end is provided with hydraulic dredge pump 9, and hydraulic dredge pump is respectively fixed with baffle plate 10 at left and right sides, square tube outer periphery A slider 4 is provided, and two lifting lugs 3 are arranged on the upper end of the slider, and a set of excavation assemblies are respectively arranged on the left and right sides of the slider, and each excavation assembly includes two hydraulic cylinders 5, an excavation arm 6 and an excavation shovel 7 .

[0012] The upper end of the square pipe is fixed to the mouth of the groove through the support rod, and the lower end of the square pipe leans against the well wall through four baffle plates around the hydraulic suction dredge pump.

[0013] The sliding piece is a square tube sleeve with hollows all around, and can slide up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com