Tail tube locking device of high-temperature solar evacuated collector tube

A technology of vacuum heat collector and exhaust tail pipe, which is applied in solar thermal devices, solar thermal power generation, heating devices, etc., can solve the problems of exhaust tail pipe damage, inconvenient operation, easy damage, etc., and achieve the effect of reducing negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

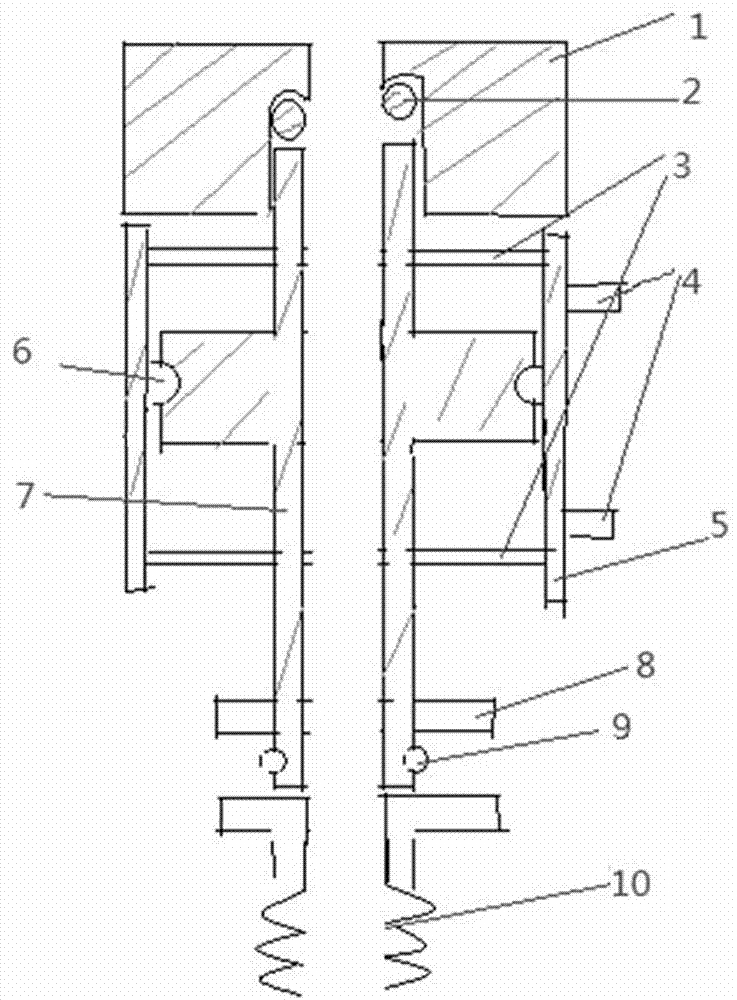

[0023] The first-level problem is to realize the efficient connection of the high-temperature pipe to the extraction equipment in the exhaust process through a fast and reliable connection. For this reason, a kind of high-temperature solar vacuum heat collecting tube exhaust tailpipe locking device is proposed, comprising:

[0024] Pipe fittings, including telescoping sections;

[0025] The cover, located at the tailpipe connection end of the pipe, is provided with a central hole coaxial with the inner hole of the pipe for the tailpipe to penetrate, and has a first joint with the pipe in the axial direction of the pipe for airtight connection. position and a disengaged second position; and

[0026] The driving mechanism is connected to the cover to drive the cover to switch between the first position and the second position.

[0027] As for the pipe fittings, as mentioned above, in order to solve the technical problem of the first level, that is, the problem of reliable conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com