An Insulated Gate Bipolar Transistor

A technology of bipolar transistors and insulated gates, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems that holes cannot be drawn away, device temperature rises, and devices burn out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

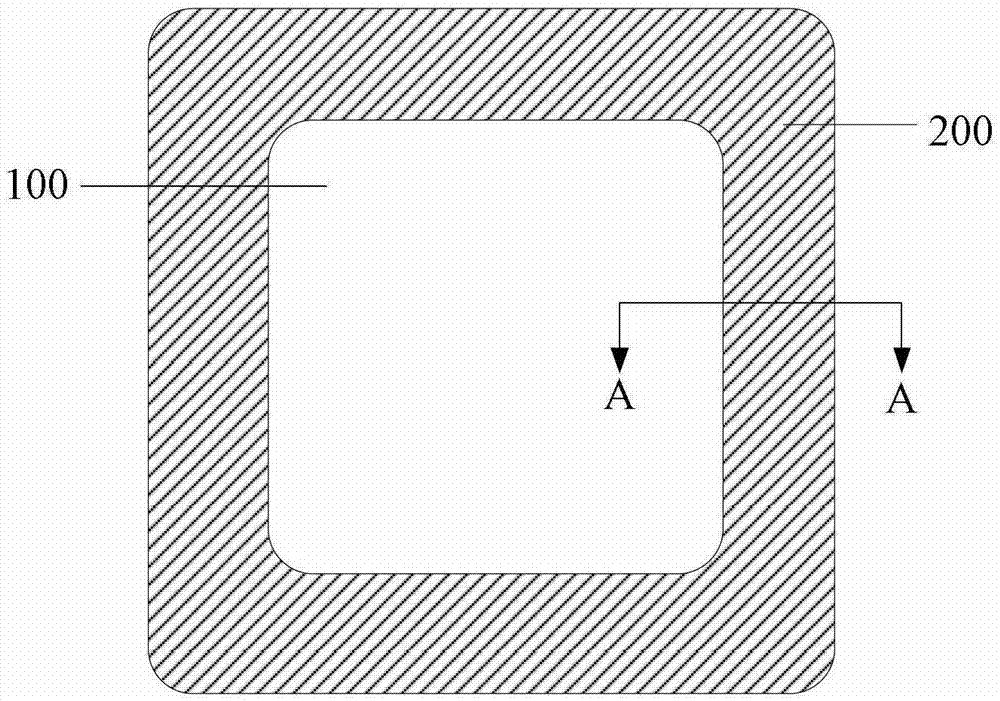

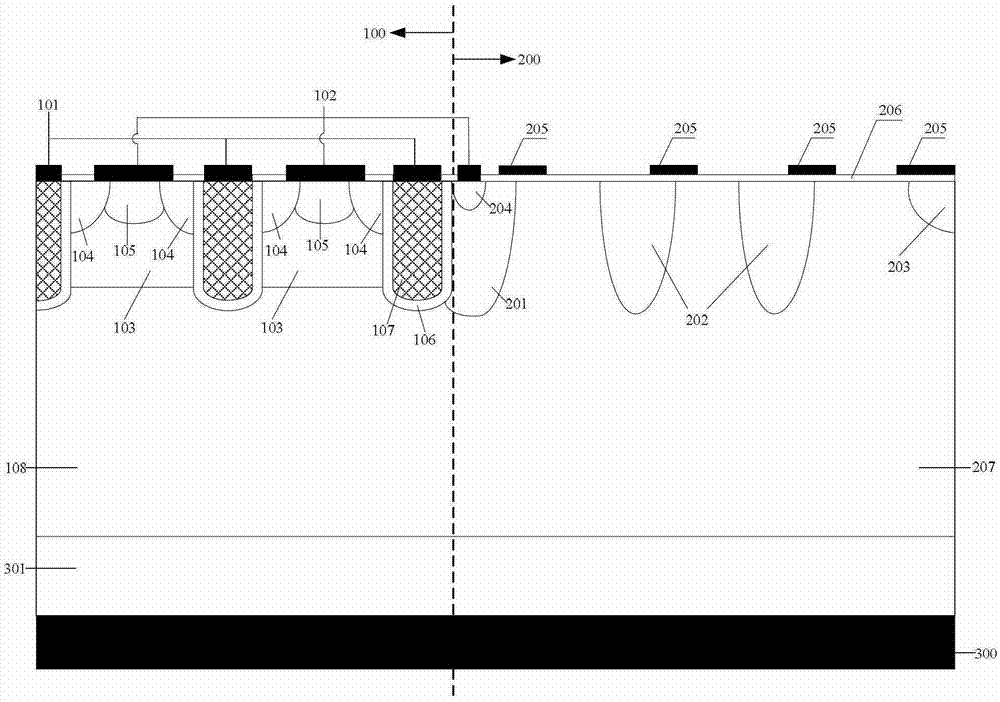

[0042] Embodiment one, such as image 3 As shown, an IGBT provided by Embodiment 1 of the present invention includes: a cell region 100 and a terminal region 200 surrounding the cell region. The cell region 100 includes a gate 101, an emitter 102, a p well region 103, an n+ emitter region 104 and a p+ emitter region 105 contained in the p well region 103 in contact with the emitter, a trench gate Region 107, gate oxide region 106, and oxide isolation layer region 206; wherein, a plurality of trench-type gate regions 107 are connected together by metal to form the gate 101 of IGBT; p well region 103 and contained in p well region The n+ emitter region 104 and the p+ emitter region 105 in 103 are connected together by metal to form the emitter 102 of the IGBT. The terminal region 200 includes a first field ring p region 201, several field ring p regions 202, a p+ region 204 connected to the emitter 102, a field plate region 205, an equipotential ring n region 203 located at the...

Embodiment 2

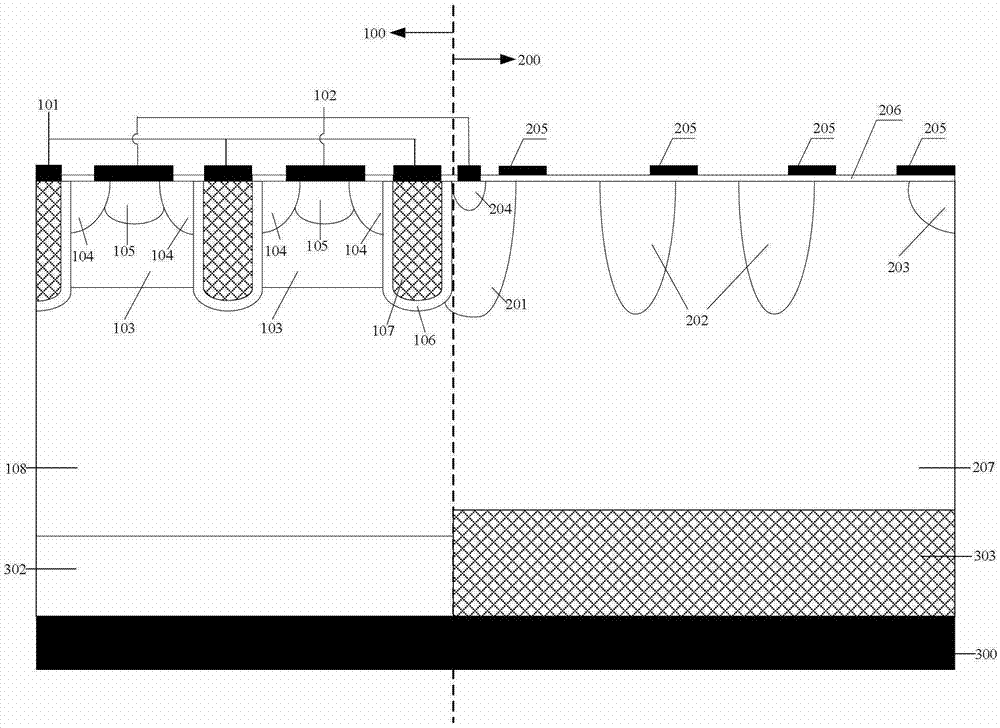

[0060] Embodiment two, such as Figure 5As shown, an IGBT provided by Embodiment 2 of the present invention includes: a cell region 100 and a terminal region 200 surrounding the cell region. The cell region 100 includes a gate 101, an emitter 102, a p well region 103, an n+ emitter region 104 and a p+ emitter region 105 contained in the p well region 103 in contact with the emitter, a trench gate Region 107, gate oxide region 106, and oxide isolation layer 206; wherein, a plurality of trench gate regions 107 are connected together by metal to form the gate 101 of the IGBT; p well region 103 and contained in p well region 103 The inner n+ emitter region 104 and p+ emitter region 105 are connected together by metal to form the emitter 102 of the IGBT. The terminal region 200 includes a first field ring p region 201, several field ring p regions 202, a p+ region 204 connected to the emitter 102, a field plate region 205, an equipotential ring n region 203 located at the edge of ...

Embodiment 3

[0075] Embodiment three, such as Figure 10 As shown, an IGBT provided by Embodiment 3 of the present invention includes: a cell region 100 and a terminal region 200 surrounding the cell region. The cell region 100 includes a gate 101, an emitter 102, a p well region 103, an n+ emitter region 104 and a p+ emitter region 105 contained in the p well region 103 in contact with the emitter, a trench gate Region 107, gate oxide region 106, and oxide isolation layer 206; wherein, a plurality of trench gate regions 107 are connected together by metal to form the gate 101 of the IGBT; p well region 103 and contained in p well region 103 The inner n+ emitter region 104 and p+ emitter region 105 are connected together by metal to form the emitter 102 of the IGBT. The terminal region 200 includes a first field ring p region 201, several field ring p regions 202, a p+ region 204 connected to the emitter 102, a field plate region 205, an equipotential ring n region 203 located at the edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com