Light emitting diode and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied to electrical components, circuits, semiconductor devices, etc., and can solve the problems of large volume of light-emitting diodes and increased manufacturing costs of light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

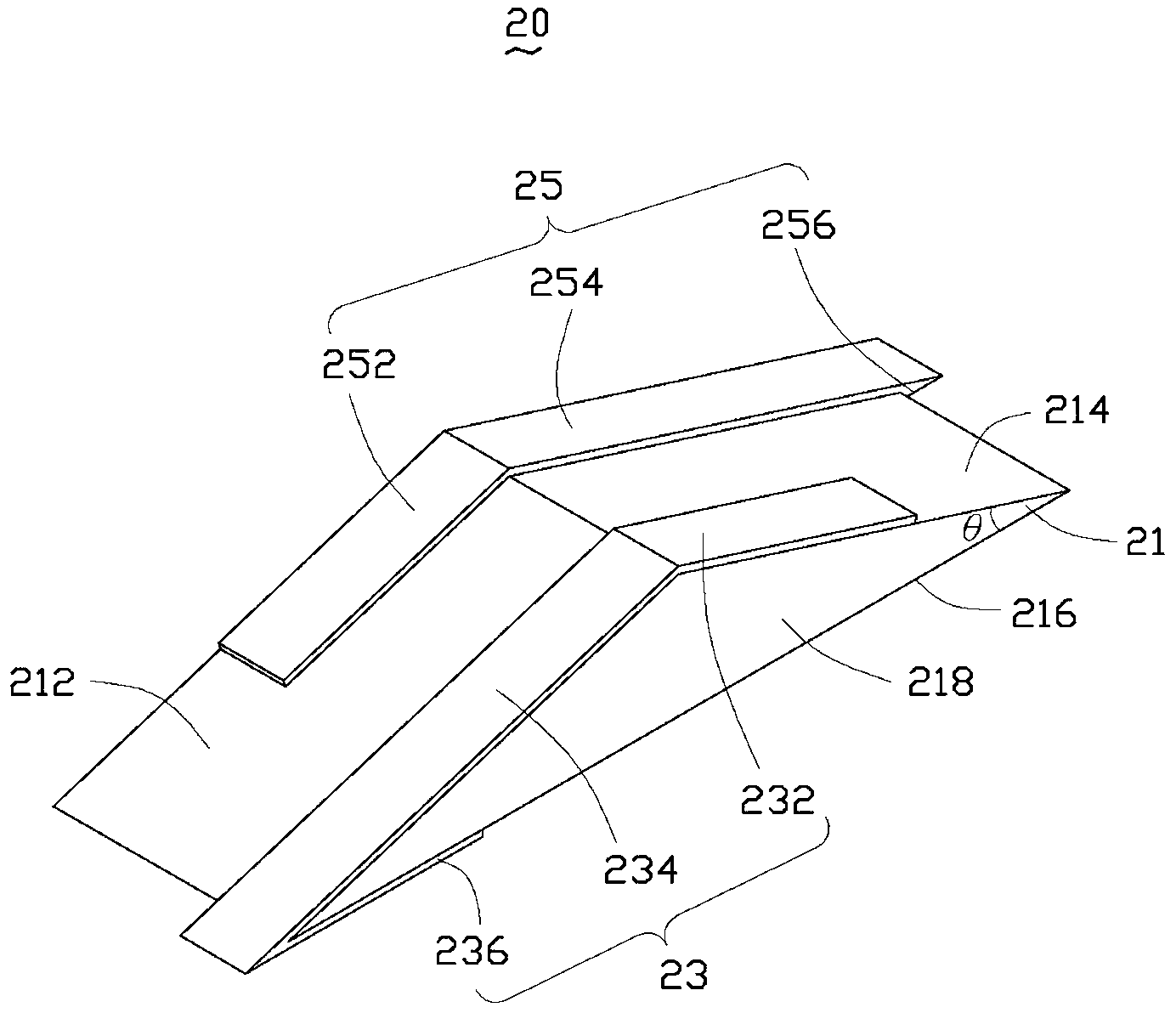

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] see Figure 1-5 , the manufacturing method of the light emitting diode 100 of the present invention mainly includes the following steps:

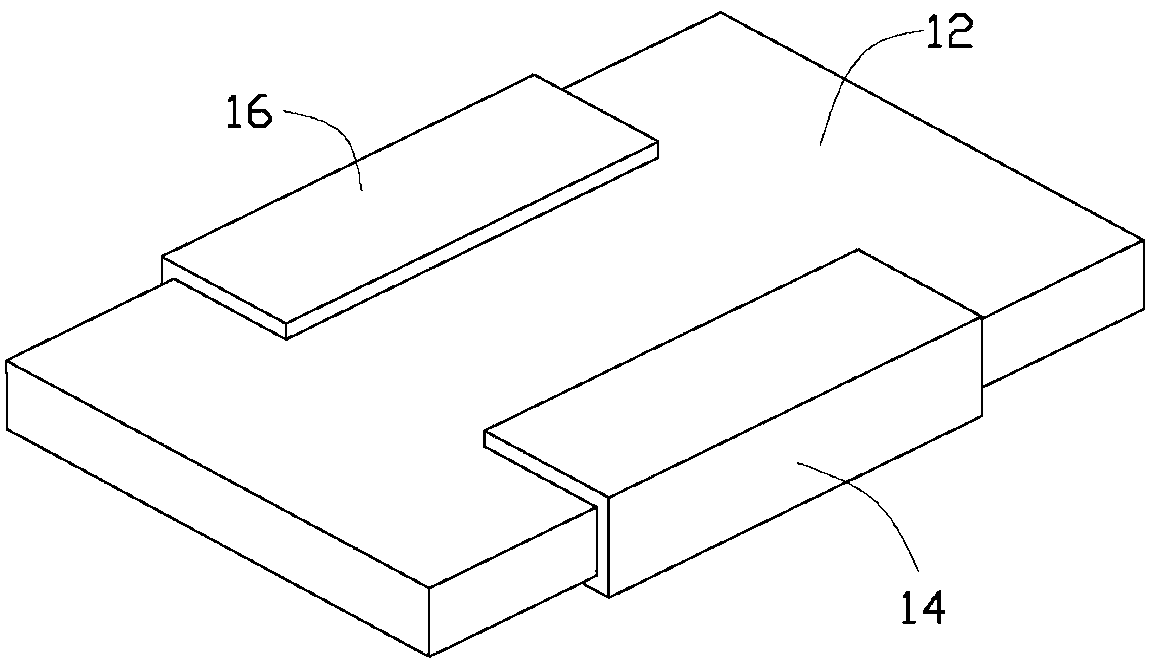

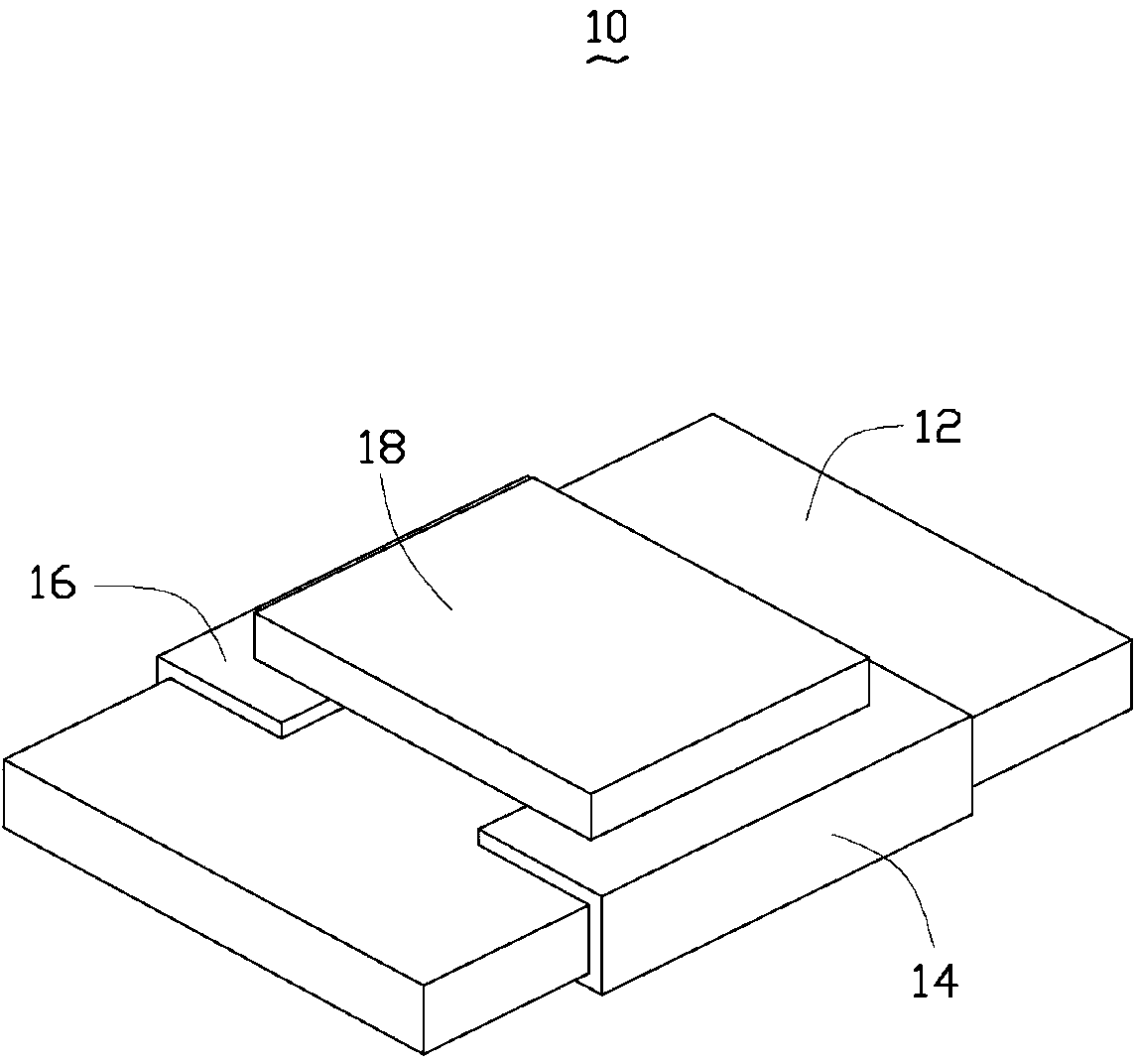

[0018] Step 1: If figure 1 As shown, a first substrate 12 is provided, the first substrate 12 is generally in the shape of a cuboid, and is made of ceramics, plastics or other insulating materials. The width direction of the first substrate 12 includes a front end and a rear end. A first metal layer 14 is attached to its front end, and a second metal layer 16 is attached to its rear end. Both the first metal layer 14 and the second metal layer 16 are bent in three sections, and are respectively attached to a part of the front end and a corresponding part of the rear end of the substrate 12 and an upper surface and a part adjacent to the part of the front end and the corresponding part of the rear end. part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com