Making device of steamed bun mixed with flour

The invention relates to a production device and a steamed bun technology, which is applied in the field of the production device of steamed buns with noodles, and can solve the problems such as the difference in the taste of noodles, the lack of noodles, and the large holes, so as to meet the dietary requirements, reduce the production cost, and improve the quality of the product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

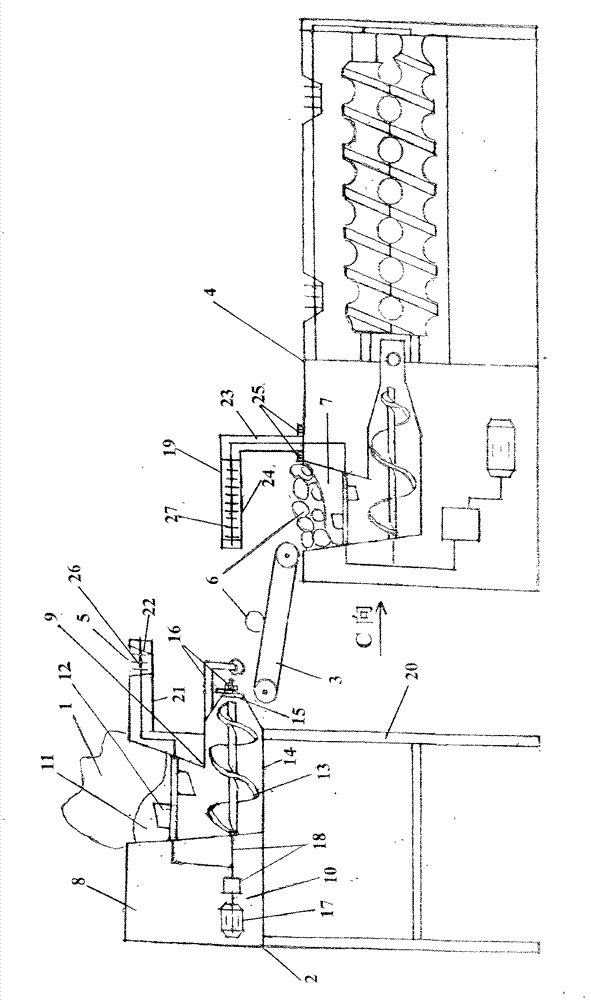

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

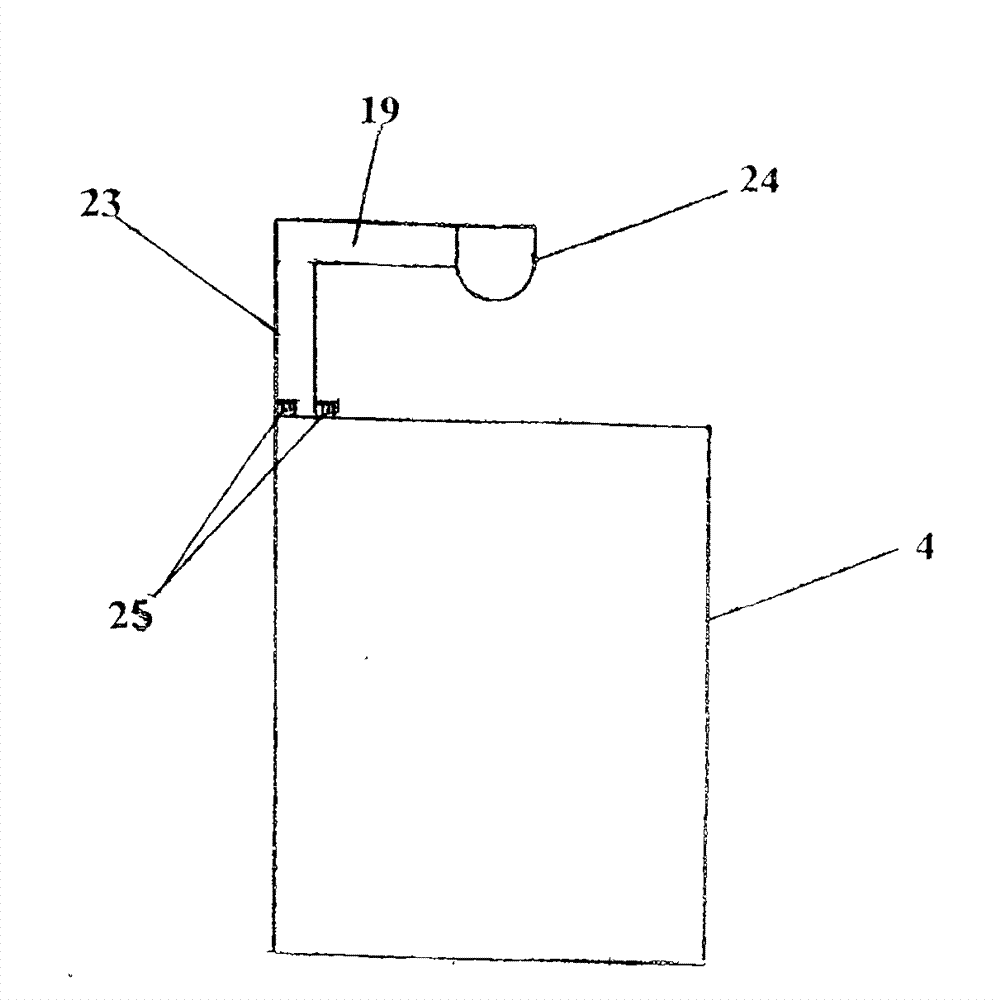

[0019] Such as figure 1 As shown, a production device for steamed buns with closed noodles includes a steamed bun machine 4 with a feed port 7, and is characterized in that it also includes a dough dividing mechanism 2, a conveying mechanism 3 and a first drying machine arranged on the dough dividing mechanism 2. Flour cloth dough hopper 5, the second dry flour cloth dough hopper 19 arranged above the feed port 7 of the steamed bun machine 4; the dough dividing mechanism 2 divides the dough 1 into dough pieces 6 of the size of steamed buns, and the dough pieces 6 Transported to the feed hopper 7 of the steamed bun machine 4 by the conveying mechanism 3, during this process, the dry flour in the first dry flour cloth dough hopper 5 falls and wraps on the outer surface of the noodle block 6, and at the same time, the second dry flour The dry flour in the cloth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com