A pump casing carrier

A carrier and pump casing technology, which is applied in the field of pump casing carriers, can solve the problems of disordered storage, unfavorable management, and large space occupation, and achieve the effects of regular storage, space saving, and convenient transfer or packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to explain the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

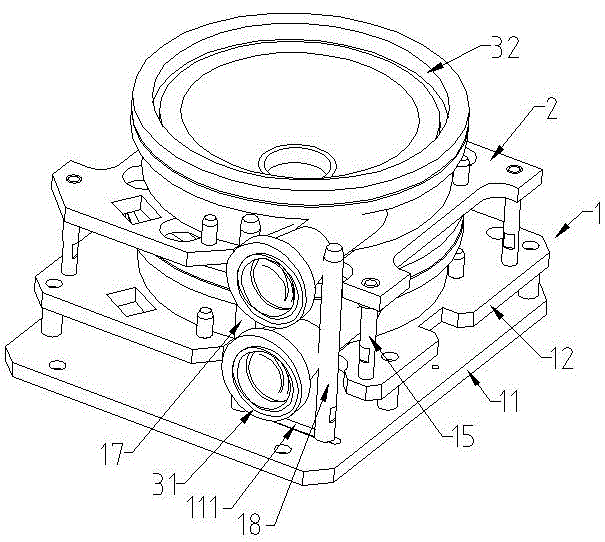

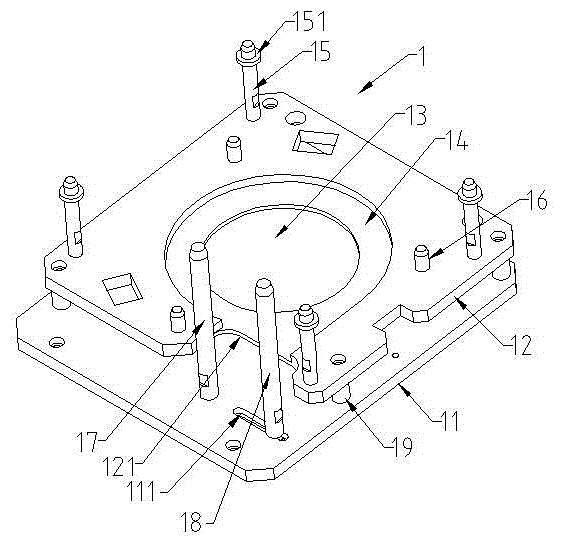

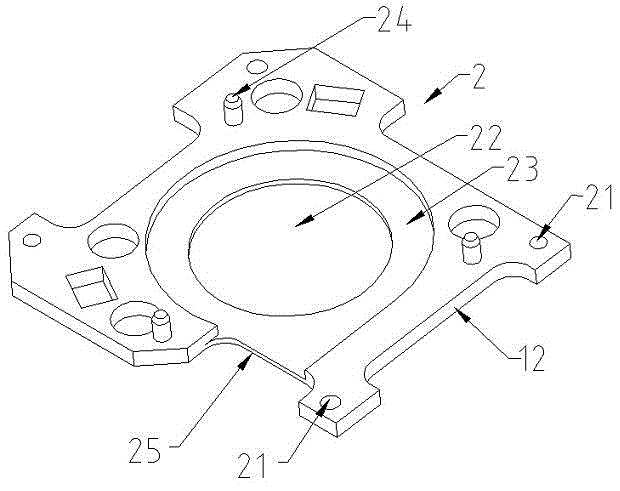

[0019] Such as figure 1 , figure 2 with image 3 As shown, the pump housing carrier of the present invention includes a carrier base 1 and a superimposed sheet 2. The superimposed sheet 2 can be superimposed on the carrier base 1. The carrier 1 includes a bottom plate 11 on which a partition plate 12 is erected through spacers 19, and a certain distance is between the bottom plate 11 and the partition plate 12. A through hole 13 is provided in the middle of the partition 12, and a shoulder 14 is provided on the edge of the through hole 13. The pump casing 31 can be placed on the partition 12 and partially contained in the through hole 13. A plurality of positioning pins 16 are also provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com