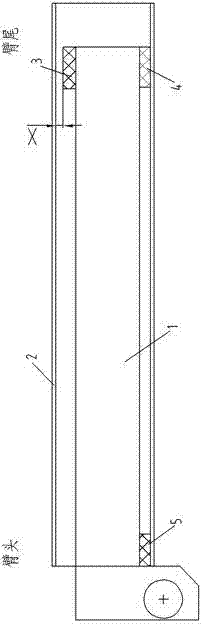

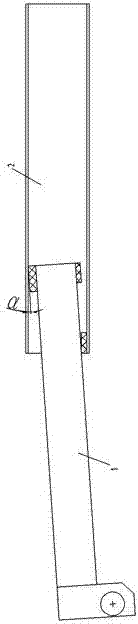

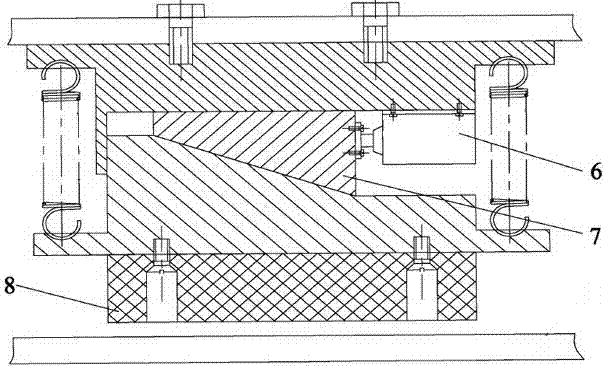

Retractable arm slide block assembly and retractable arm

A telescopic arm and slider technology, applied in the field of telescopic arms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Heat to 250°C in a vacuum heat treatment furnace and hold for 30 minutes, continue to heat to 540°C, and hold for 60 minutes, continue to heat to 990°C, and hold for 250 minutes, slowly cool to 660°C, hold for 120 minutes, and slowly cool to 530 Baked out below ℃, sprayed for rapid cooling after coming out;

[0043] 2) Then put it into the nitrogen furnace, heat it to 260°C, and keep it warm for 60 minutes, continue to heat it to 520°C, and keep it warm for 180 minutes, then cool the furnace to 300°C and then quickly air cool it under the direct blowing of the fan;

[0044] 3) Then put it into a 90KW box-type resistance furnace for heating, heat it to 200°C, keep it warm for 300min, and then take it out of the furnace to air-cool or furnace-cool.

[0045] After the above treatment, the slider body, guide sleeve and slider, compared with untreated high-chromium cast iron, have Rockwell hardness HRC>60, and the wear resistance is improved by at least 34%, which increas...

Embodiment 2

[0047] 1) Heat to 260°C in a vacuum heat treatment furnace, keep it for 35 minutes, continue heating to 540°C, keep it for 70 minutes, continue heating to 1000°C, keep it for 250 minutes, slowly cool to 660°C, keep it for 120 minutes, and slowly cool to 530 Baked out below ℃, sprayed for rapid cooling after coming out;

[0048] 2) Put it into the nitrogen furnace again, heat it to 260°C, and keep it warm for 60 minutes, continue to heat it to 520°C, and keep it warm for 190 minutes, then cool the furnace to 300°C and then quickly air cool it under the direct blowing of the fan;

[0049] 3) Then put it into a 90KW box-type resistance furnace for heating, heat it to 200°C, keep it warm for 300min, and then take it out of the furnace to air-cool or furnace-cool.

[0050] After the above treatment, the slider body, guide sleeve and slider, compared with untreated high-chromium cast iron, have Rockwell hardness HRC>60, and the wear resistance is improved by at least 34%, which incr...

Embodiment 3

[0052] 1) Heat to 270°C in a vacuum heat treatment furnace, keep it for 40 minutes, continue heating to 540°C, keep it for 80 minutes, continue heating to 1010°C, keep it for 250 minutes, slowly cool to 660°C, keep it for 120 minutes, and slowly cool to 530 Baked out below ℃, sprayed for rapid cooling after coming out;

[0053] 2) Then put it into the nitrogen furnace, heat it to 260°C, and keep it warm for 60 minutes, continue to heat it to 520°C, and keep it warm for 200 minutes, then cool the furnace to 300°C and then quickly air-cool it under the direct blowing of the fan;

[0054] 3) Then put it into a 90KW box-type resistance furnace for heating, heat it to 200°C, keep it warm for 300min, and then take it out of the furnace to air-cool or furnace-cool.

[0055] After the above treatment, the slider body, guide sleeve and slider, compared with untreated high-chromium cast iron, have Rockwell hardness HRC>60, and the wear resistance is improved by at least 34%, which incre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com