Method for detecting barley seed purity by two-dimensional electrophoresis technology

A two-dimensional electrophoresis and purity technology, which is applied in the preparation of test samples and electrochemical variables of materials, etc., can solve the problems of malting and beer companies' losses, price differences, and the inability to accurately detect purity, etc., and achieve the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

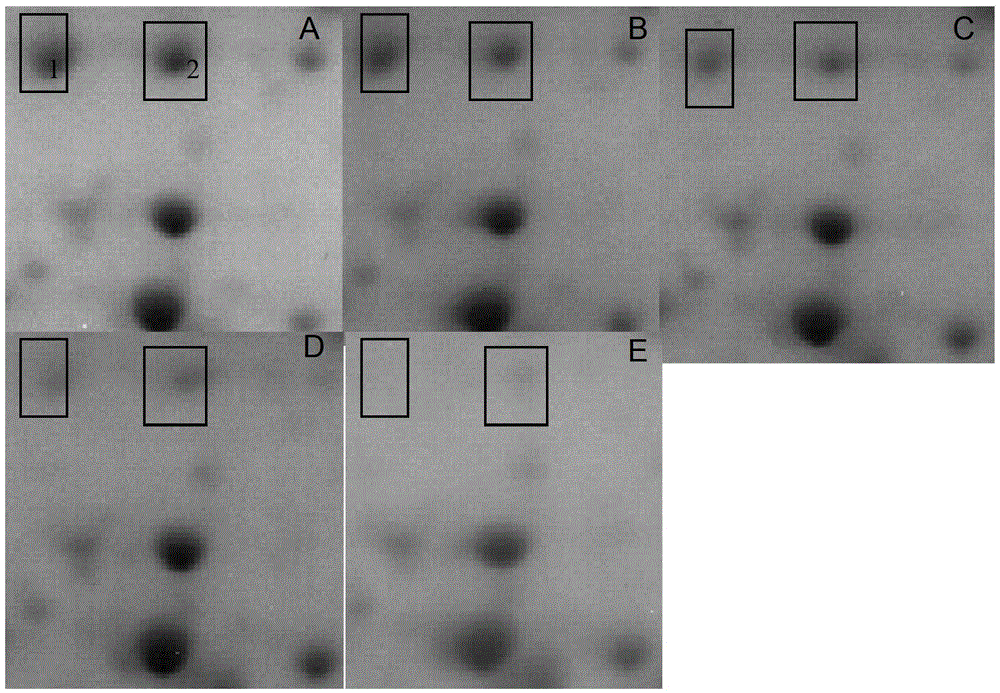

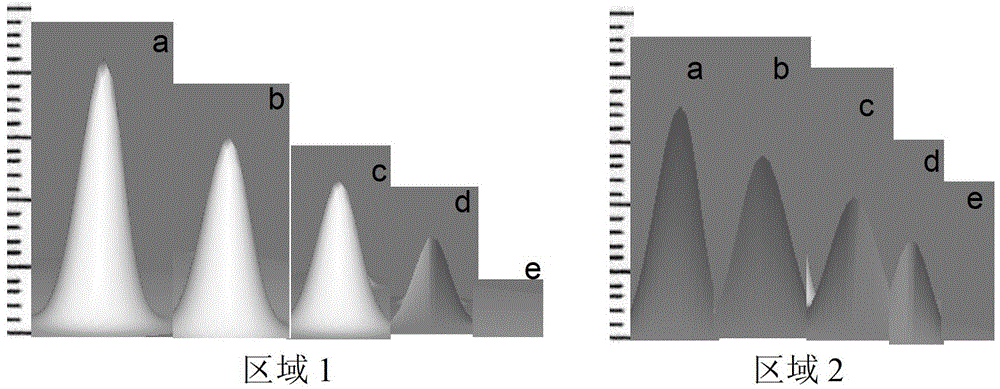

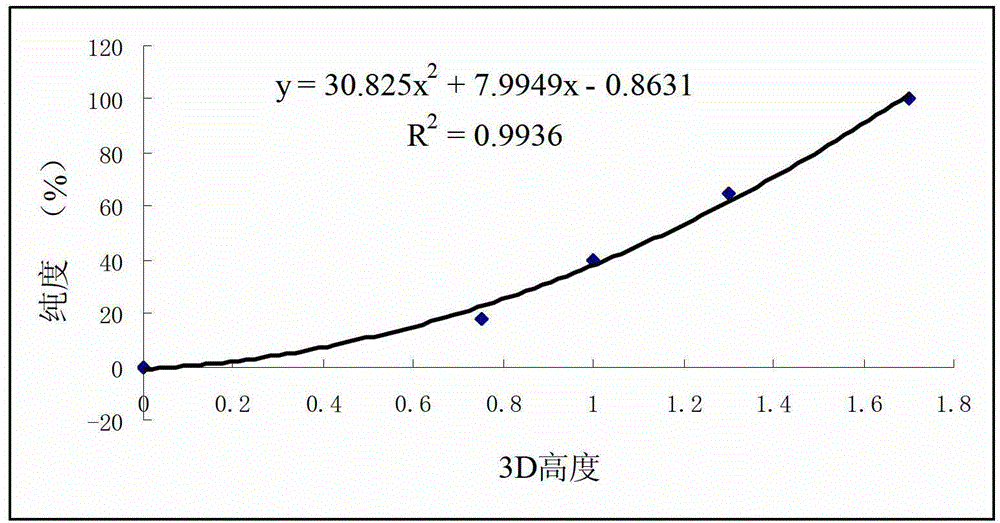

[0031] Example 1. Standard Curve 1 of Barley Purity and Differential Protein 3D Map Height

[0032] The first step, protein extraction:

[0033] Ganpier No.4 purebred barley samples were taken as Ganpier No.4 barley with the purity of 100, 65, 40, 18, and 0% mixed with Shan 2. After manual peeling, grind with liquid nitrogen, take 0.3g sample and add 3 times the volume of extract solution to extract at room temperature for 2h. Centrifuge at 10,000 g for 10 min, take the supernatant and add an equal volume of Tris-balanced phenol at pH 8.8, and extract at room temperature for 30 min. Centrifuge at 10000g for 10min, suck out the supernatant, and extract Tris-balanced phenol again. The two parts of the phenol phase were combined and added with 4 times the volume of cleaning solution A, extracted at -80°C for 3 hours, and centrifuged at 10,000g for 10 minutes. The protein obtained by centrifugation was washed with cleaning solution A and cleaning solution B respectively, centri...

Embodiment 2

[0042] Example 2. Standard Curve 2 of Barley Purity and Differential Protein 3D Map Height

[0043] The first step, protein extraction:

[0044]Ganpier No.4 purebred barley samples were taken as Ganpier No.4 barley with the purity of 100, 65, 40, 18, and 0% mixed with Shan 2. After manual peeling, grind with liquid nitrogen, take 0.3g sample and add 3 times the volume of extract solution to extract at room temperature for 2h. Centrifuge at 10,000 g for 10 min, take the supernatant and add an equal volume of Tris-balanced phenol at pH 8.8, and extract at room temperature for 30 min. Centrifuge at 10000g for 10min, suck out the supernatant, and extract Tris-balanced phenol again. The two parts of the phenol phase were combined and added with 4 times the volume of cleaning solution A, extracted at -80°C for 3 hours, and centrifuged at 10,000 g for 10 minutes. The protein obtained by centrifugation was washed with cleaning solution A and cleaning solution B respectively, centri...

Embodiment 3

[0053] Embodiment three, sample a purity detection

[0054] Take Ganpier No. 4 purebred barley and Dan No. 2 as a mixed species to obtain a Ganpier No. 4 barley sample with a purity of 50%. The extraction and differential protein spot 3D map heights are the same as those in Examples 1 and 2. The protein spot height in area 1 is 1.3, the purity of the area brought into the standard is 49%, and the error is 1%; the height of the protein spot in area 2 is 1.1, the purity of the area brought into the standard is 45.2%, and the error is 4.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com