An Integral Buckle Stopper with Variable Wall Thickness and Side Plates

A buckling stopper, an integral technology, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. problem, to achieve the effect of preventing buckling propagation, light weight, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

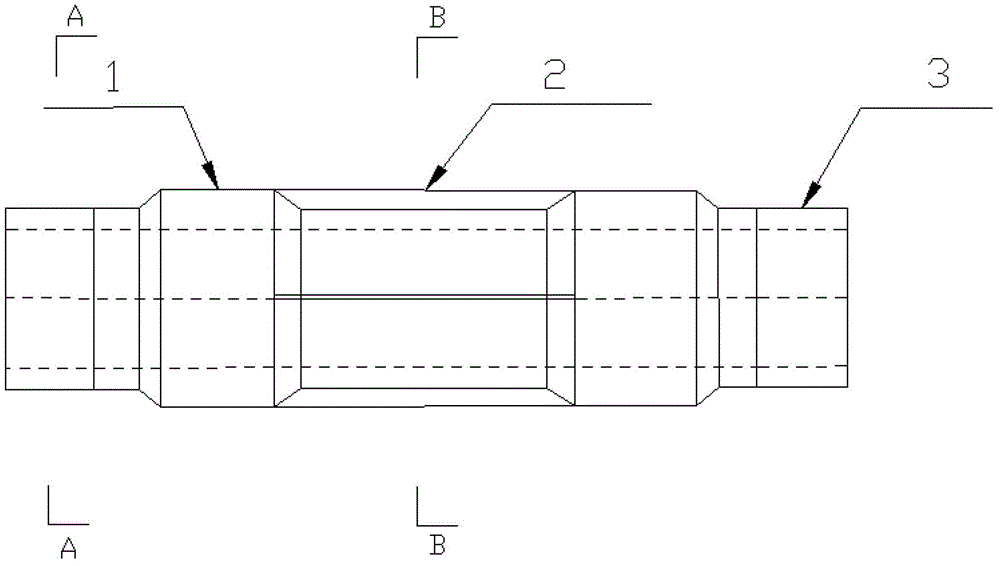

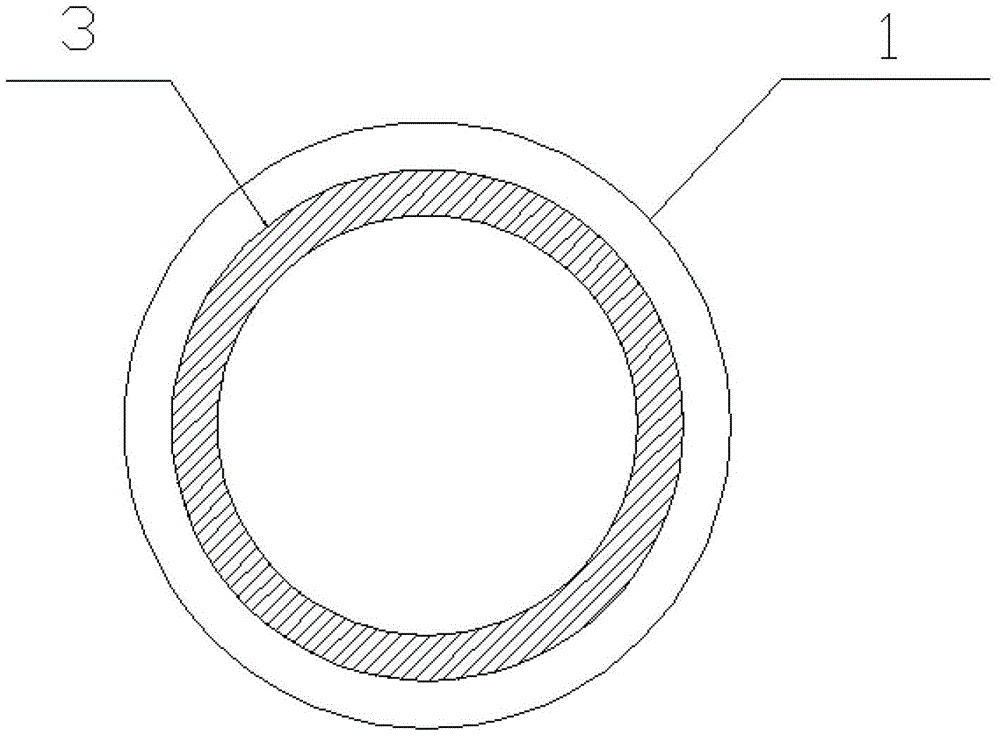

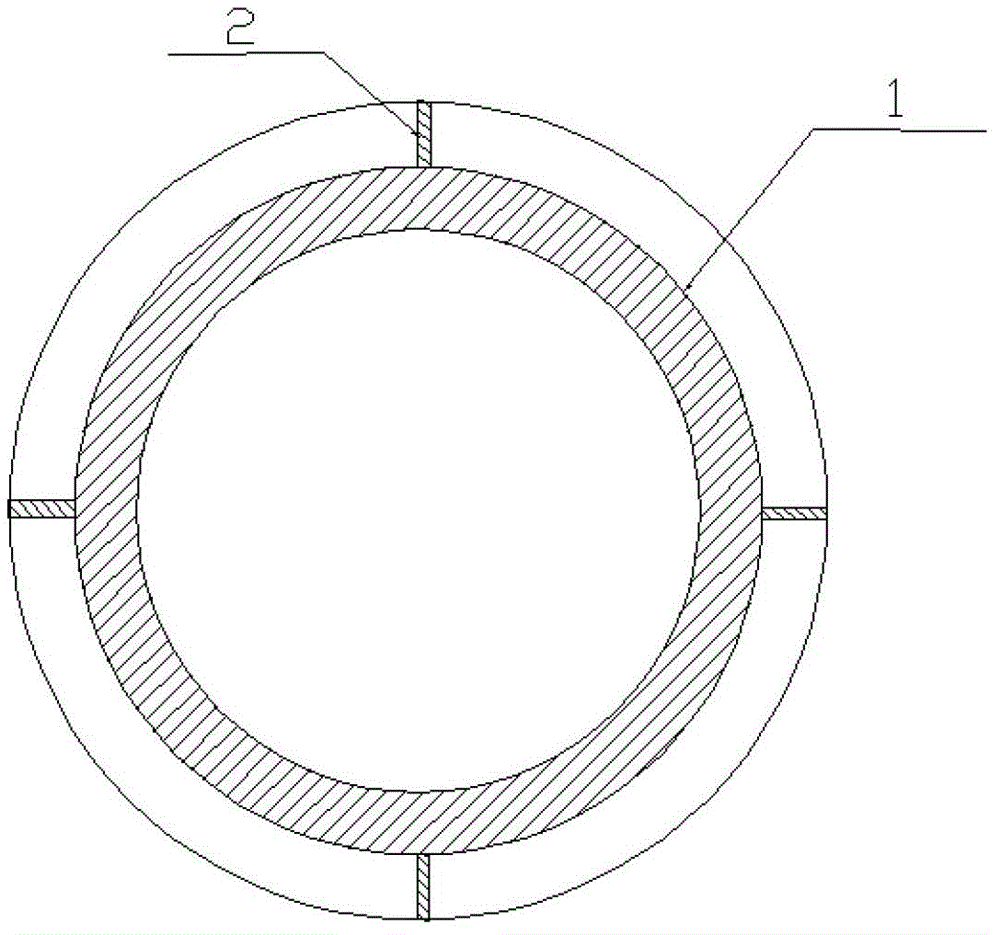

[0026] like Figures 1 to 3 As shown, the structural features of the bend arrester of the present invention are as follows:

[0027] 1) The present invention is a combination structure composed of a variable-wall-thickness integral buckle arrester main body 1 and four side plates 2 . The integral material should adopt API5L X65 type or higher grade steel of the same material as the deepwater submarine pipeline 3. The side panels should be made of API5L X70 grade steel. The main function of the device is to prevent the buckling propagation of the submarine pipeline during installation or operation, and ensure the overall safety of the pipeline.

[0028] 2) The length of the main body 1 of the integral anti-bend device is 4-6 times the diameter of the pipe, the thickness of both ends of the main body 1 of the integral anti-bend device is 2-4 times the thickness of the pipe, and the thickness of the middle part of the main body 1 of the anti-bend device is two ends 1 / 2 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com