Deepwater pipeline buckle arrestor reinforcing method

A technology for deep-water pipelines and buckling stoppers, which is used in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc., can solve the problem of poor buckling stopper effect, difficult replacement and installation of snap-in buckling stoppers, and difficulties in reinforcement. and other problems, to achieve the effect of cost reduction, stability and safety, and common structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

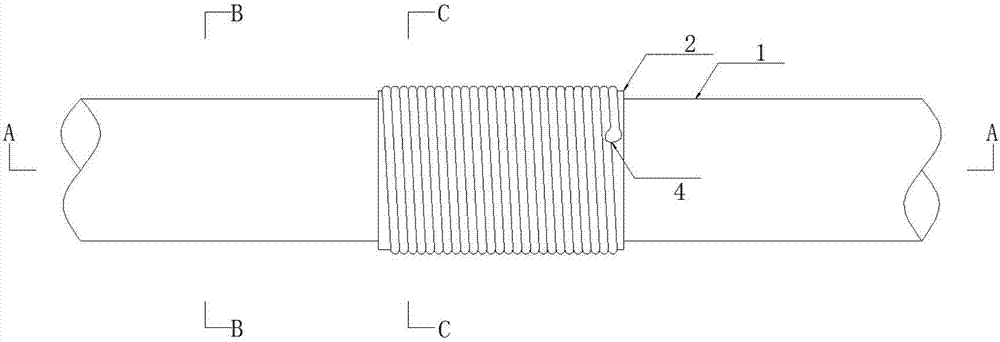

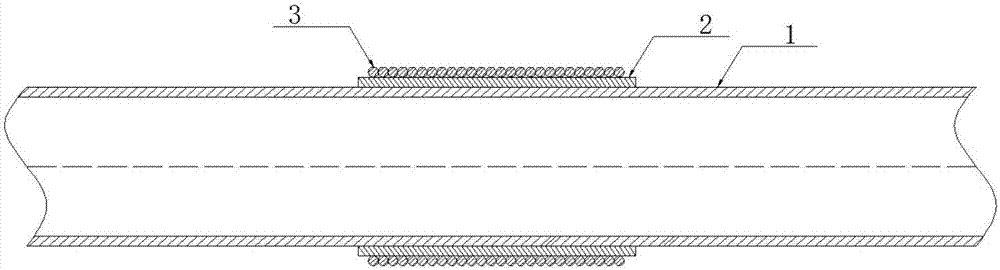

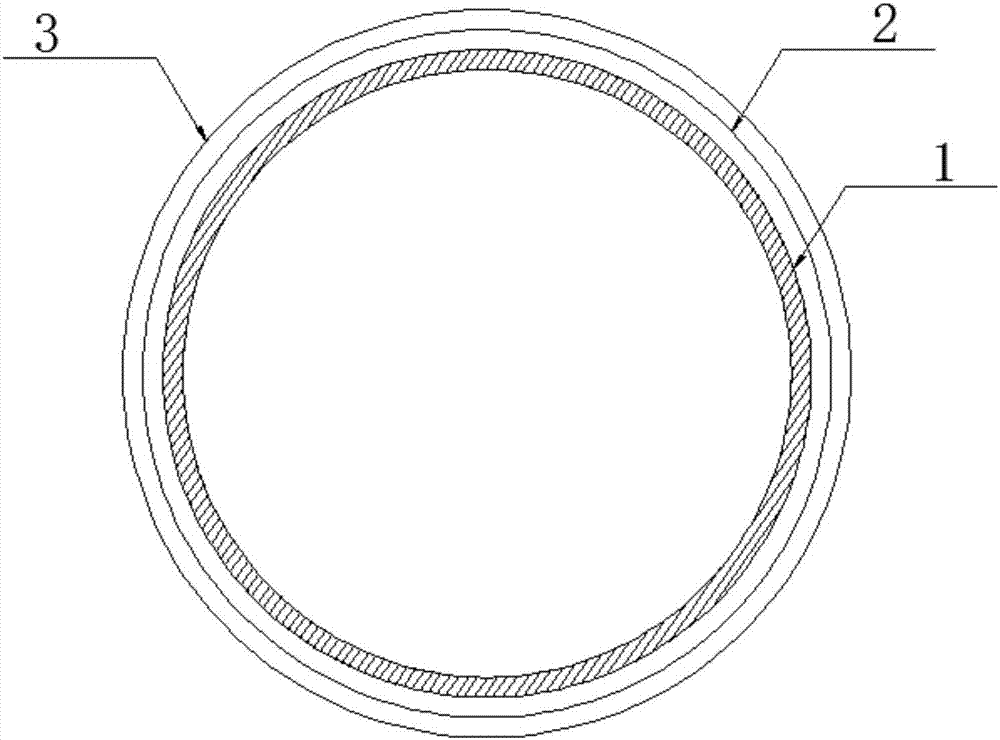

[0022] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0023] Such as figure 1 As shown, the present invention includes a snap-in buckle arrester 2 , a wrap-around buckle arrester 3 and a subsea pipeline 1 . The material of the buckle arrester is API 5L X65 or higher grade steel that is the same material as the subsea pipeline 1. The function of the winding-type buckle arrester 3 is to reinforce and maintain the structure of the submarine pipeline 1 and the snap-in buckle arrester 2 that are likely to be deformed or have already been deformed by using the flexible installation method of the buckle arrester 3 during winding, so as to The local hoop stiffness of the submarine pipeline 1 is improved, buckling propagation of the submarine pipeline 1 is prevented, and stability and safety are improved.

[0024] Such as figure 1 with figure 2 As shown, the snap-in buckle arrester 2 is a cylindrical shell structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com