Curling preventor of axial compression fatigue experiment

A fatigue test and axial compression technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problem that the anti-curve device has poor anti-curve effect, affects the accuracy of test results, and hinders the sample. telescopic deformation and other problems, to prevent slippage, good anti-bending effect, and avoid vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

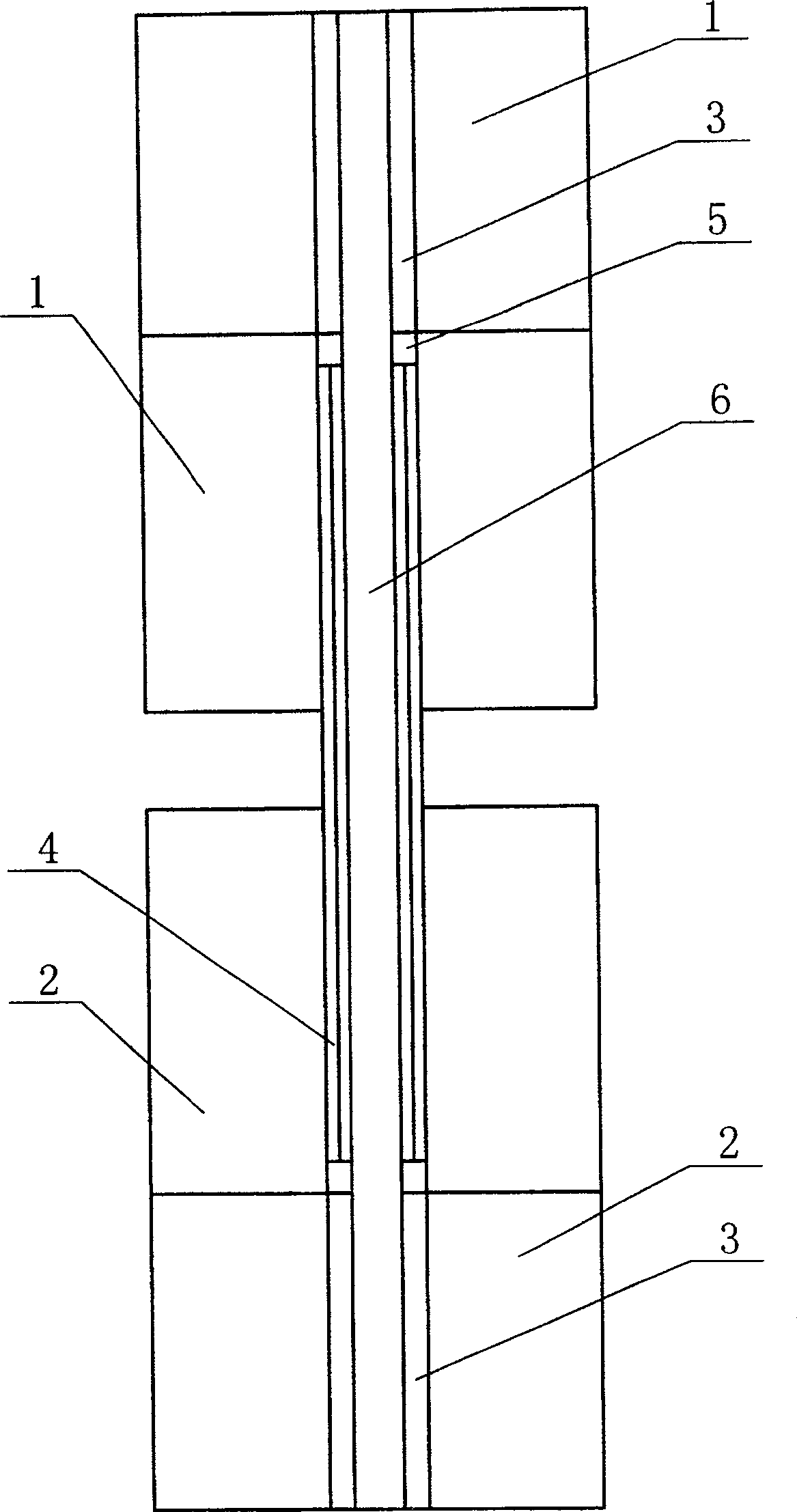

Embodiment : pic 1, 1 specific Embodiment approach

[0010] Example: figure 1 Shown is a specific embodiment of the present invention: an anti-bending device for axial compression fatigue test, including a pair of anti-bending splints, which are used for anti-bending of sample 6. The paired anti-bending splints are upper and lower pairs 1 and 2, and the upper pair of anti-bending splints 1 and the lower pair of anti-bending splints 2 respectively clamp the upper half and the lower half of the sample 6.

[0011] The inner surfaces of the upper and lower pairs of anti-bending splints 1 and 2 that are in contact with the sample 6 are lined with anti-slip linings 3 along the axial direction near the end of the sample, and anti-bending linings are placed near the middle of the sample Plate 4, the coefficient of friction of the anti-skid lining 3 is greater than that of the anti-bending lining 4.

[0012] The anti-bending liner 4 is more than two layers (including two layers).

[0013] The anti-skid liner 3 is made of polyester cott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com