High-toughness and heat-resistant nodular cast iron for exhaust manifolds and preparation technology of high-toughness and heat-resistant nodular cast iron

A technology of exhaust manifold and ductile iron, which is applied in the field of high-toughness heat-resistant ductile iron and its preparation technology, can solve the problems of low fuel combustion efficiency and low power, and achieve the effect of increasing anti-bending effect and mitigating the reduction of service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

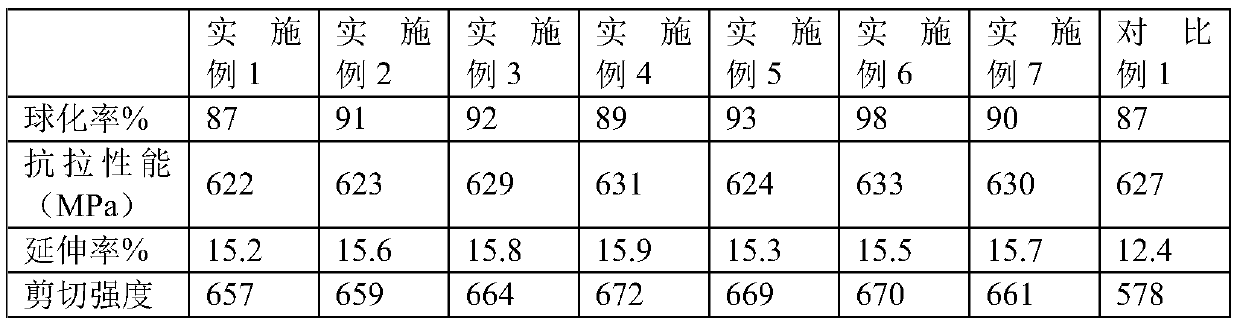

Examples

Embodiment 1

[0029] Embodiment 1, a kind of preparation method of the high-toughness heat-resistant ductile iron that is used for exhaust manifold, comprises the following steps:

[0030] Step 1: Raw material preparation: nodulizers, inoculants, low-sulfur carburizers, slag removers, and alloys are placed on site. The nodulizers use Ca and Ba-containing low rare earth nodulizers: QRMg8Re3; the inoculants use Si- Ba inoculant, the Ba content of the inoculant is 6%;

[0031] Step 2: Preparation of spheroidizing bag and pouring bag: remove the debris in the spheroidizing bag before use, and check whether the refractory material has fallen off in the pouring bag;

[0032] Step 3: Sampling and testing the molten iron after melting;

[0033] Step 4: Nodulization, agent inoculant filling, put nodulizer into the dam of the nodulization bag, cover the top with the inoculant, and then cover the top with the slag remover, put into the nodulization bag once inoculated to be 1.6% of the molten steel q...

Embodiment 2

[0038] Embodiment 2, a kind of preparation method for the high toughness heat-resistant ductile iron of exhaust manifold, comprises the following steps:

[0039] Step 1: Raw material preparation: nodulizers, inoculants, low-sulfur carburizers, slag removers, and alloys are placed on site. The nodulizers use Ca and Ba-containing low rare earth nodulizers: QRMg8Re3; the inoculants use Si- Ba inoculant, the Ba content of the inoculant is 5%; step 2: preparation of the nodularization bag and pouring bag: remove the sundries in the nodularization bag before use, and check whether the refractory material has fallen off in the pouring bag;

[0040] Step 3: Sampling and testing the molten iron after melting;

[0041] Step 4: Nodulization, agent inoculant filling, put the nodulizer into the dam of the nodulization bag, cover the above with the inoculant, and then cover the top with the slag remover, put into the nodulization bag once inoculated to be 1.3% of the molten steel quality, s...

Embodiment 3

[0044] Embodiment 3, a kind of preparation method for the high toughness heat-resistant ductile iron of exhaust manifold, comprises the following steps:

[0045] Step 1: Raw material preparation: nodulizers, inoculants, low-sulfur carburizers, slag removers, and alloys are placed on site. The nodulizers use Ca and Ba-containing low rare earth nodulizers: QRMg8Re3; the inoculants use Si- Ba inoculant, the Ba content of the inoculant is 4%;

[0046] Step 4: Nodulization, agent inoculant filling, put the nodulizer into the dam of the nodulization bag, cover the top with the inoculant, and then cover the top with the slag remover, put into the nodulization bag once inoculated to be 1% of the molten steel mass, so Said nodulizer addition (%)=30a+b, a is sulfur content in molten iron, b is coefficient, b=0.35;

[0047] Step 5: After the molten iron is poured into the spheroidizing bag, add a secondary inoculant, the secondary inoculation is 0.2 times the mass of the spheroidizing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com