Jig for detecting concentricity of jet nozzle

A technology for detecting jig and concentricity, applied in measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of low utilization rate and low efficiency of measuring beds, and achieve time-saving, convenient detection, and friction reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

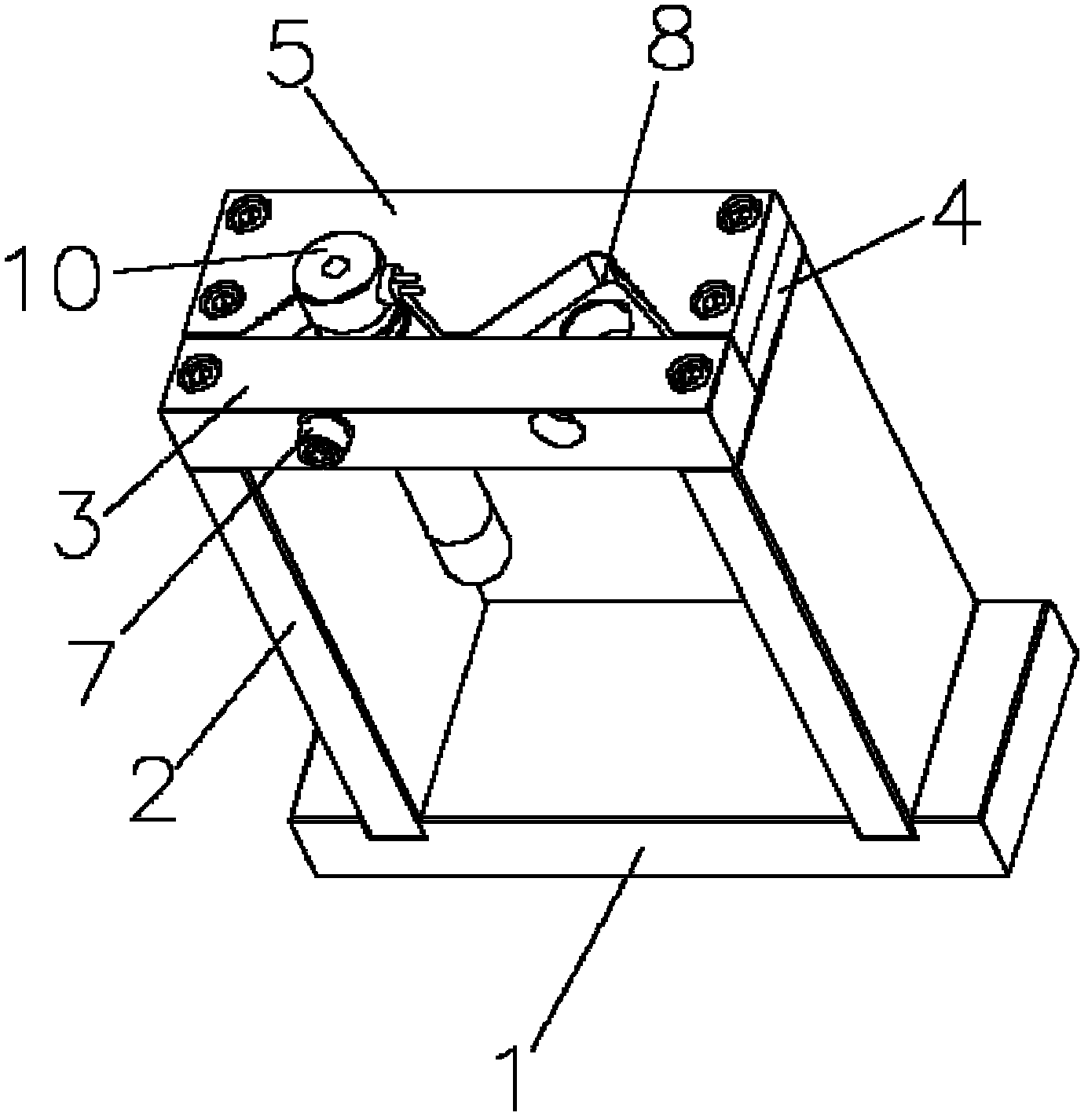

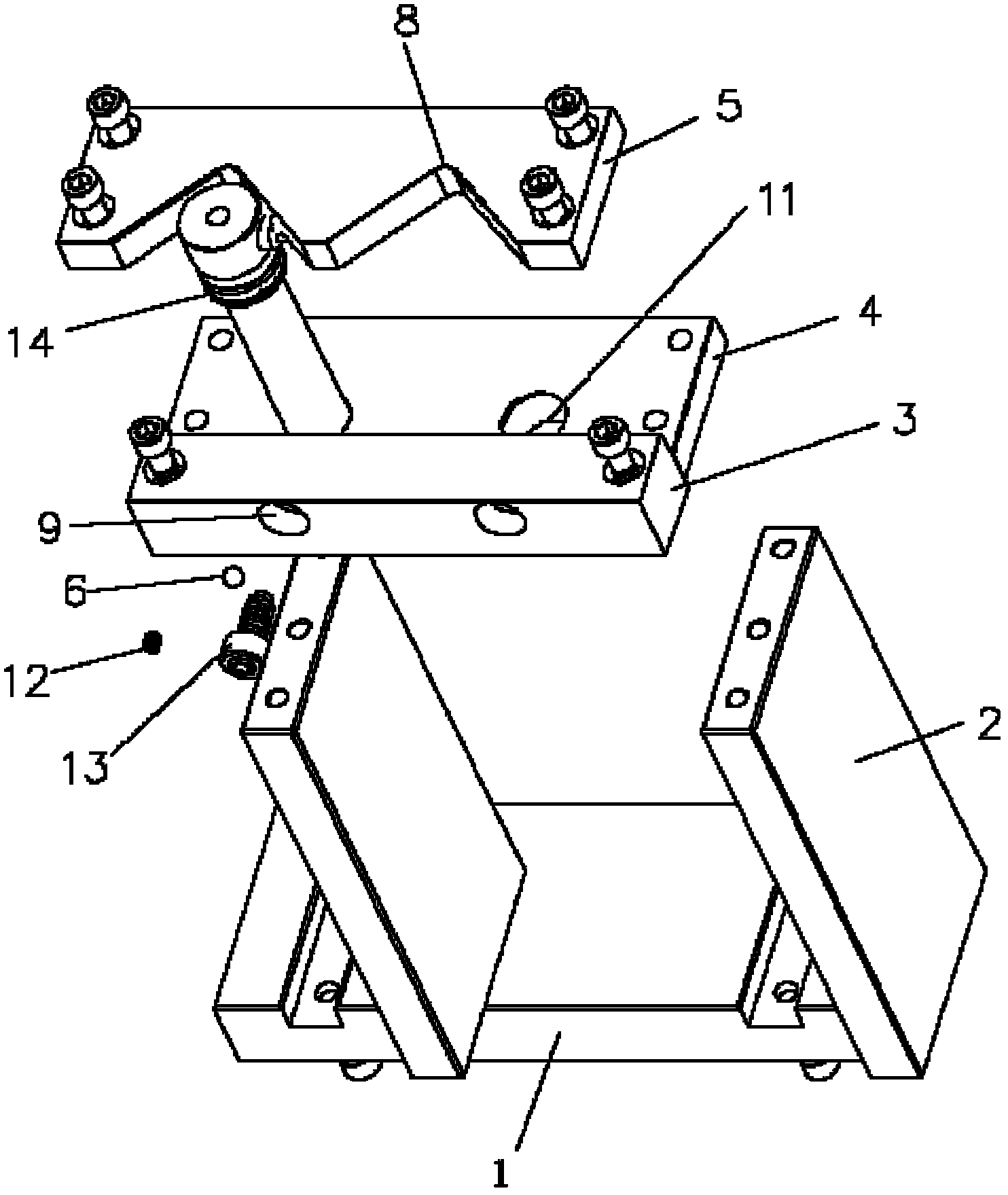

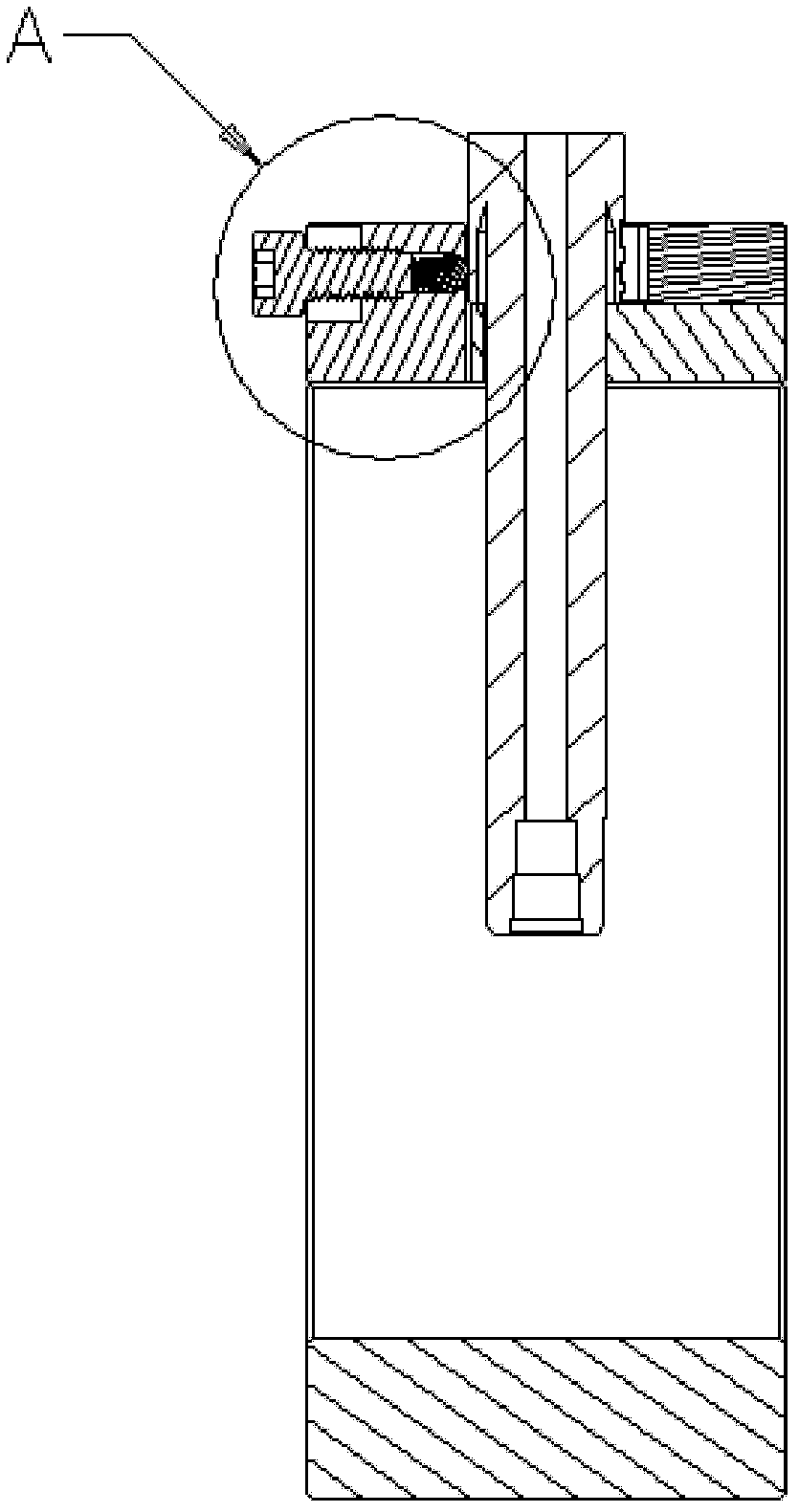

[0022] A nozzle concentricity detection jig, comprising a base plate 1, a support plate 2, a marble adjustment plate 3, a workpiece carrying plate 4, a positioning plate 5, a marble 6 and a pressing mechanism 7, the support plates are two pieces, and The interval is fixed above the base plate; the workpiece carrying plate is fixed above the two pillar plates; the marble adjustment plate is fixed on the upper side of the workpiece carrying plate, and the positioning plate is fixed on the The other side above the workpiece carrying plate; the positioning plate is provided with at least one V-shaped notch 8 near the end of the pinball adjusting plate, and a V-shaped notch is provided on the pinball adjusting plate facing the V-shaped notch. The through hole 9 that can just accommodate the marbles, and the pressing mechanism can just drive the marbles to move in the through hole; A workpiece hole 11 having a larger outer diameter than the nozzle 10 to be tested. When in use, one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com