Material taking hole opening and closing device, coal cake sampling measurement device and coal cake sampling measurement method

A technology of opening and closing devices and retrieving devices, which is applied in the direction of measuring devices, sampling devices, and specific gravity measurements, can solve the problems of inability to monitor the density of briquettes in real time, the accuracy of measurement density is not high, and the density of tamping is not high. Avoid the influence of measurement results, realize real-time monitoring, and reduce the effect of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the invention is capable of various changes in different embodiments without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

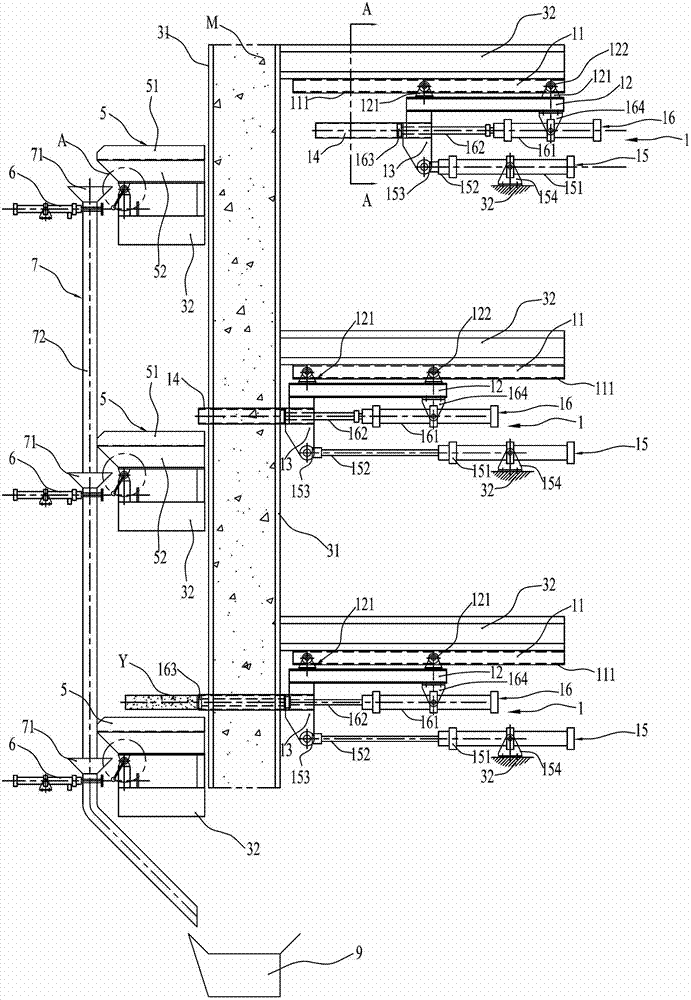

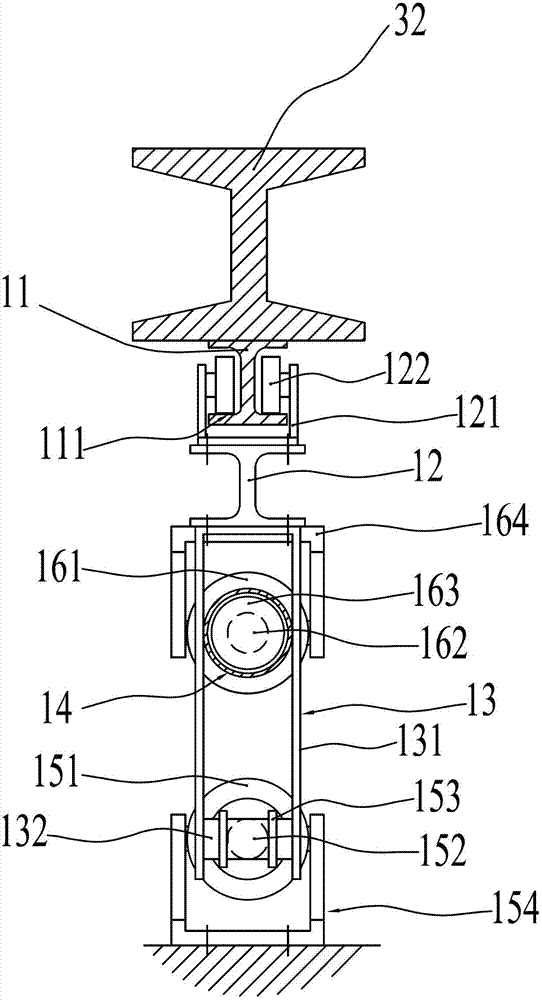

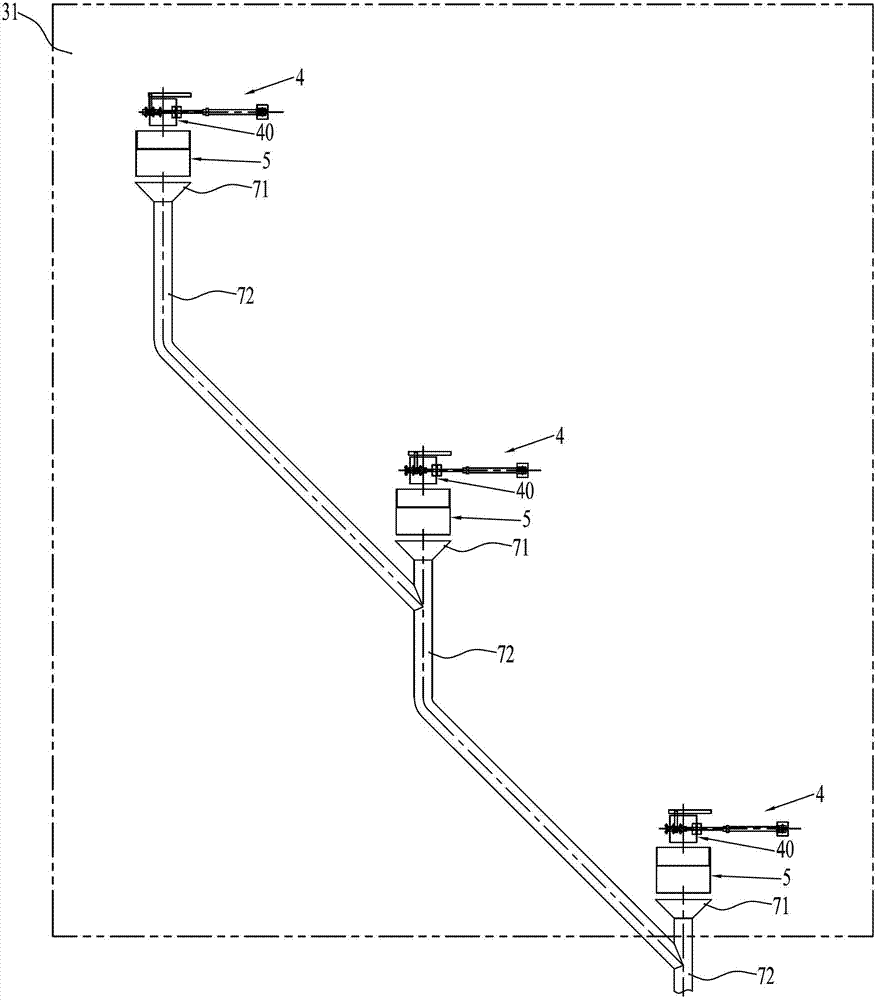

[0040] Such as figure 1 , image 3 As shown, the present invention provides a kind of briquette sampling and measuring device, comprising: a material taking device 1, a material taking hole opening and closing device 4 and a briquette density measuring device 5; The material device 1 and the briquette density measuring device 5 are installed under the reclaiming device 1 , and the briquette density measuring device 5 can weigh a specified volume of coal sample taken out by the reclaiming device 1 .

[0041] Such as figure 1 As shown, the coal cake retrieving device 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com