A device and method for measuring the compactness of rockfill concrete

A rockfill concrete and measurement method technology, which is applied in the field of engineering construction, can solve problems such as unsatisfactory detection results, technical level and judgment method influence, and achieve simple and easy-to-understand working principle, low comprehensive use cost, and small workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

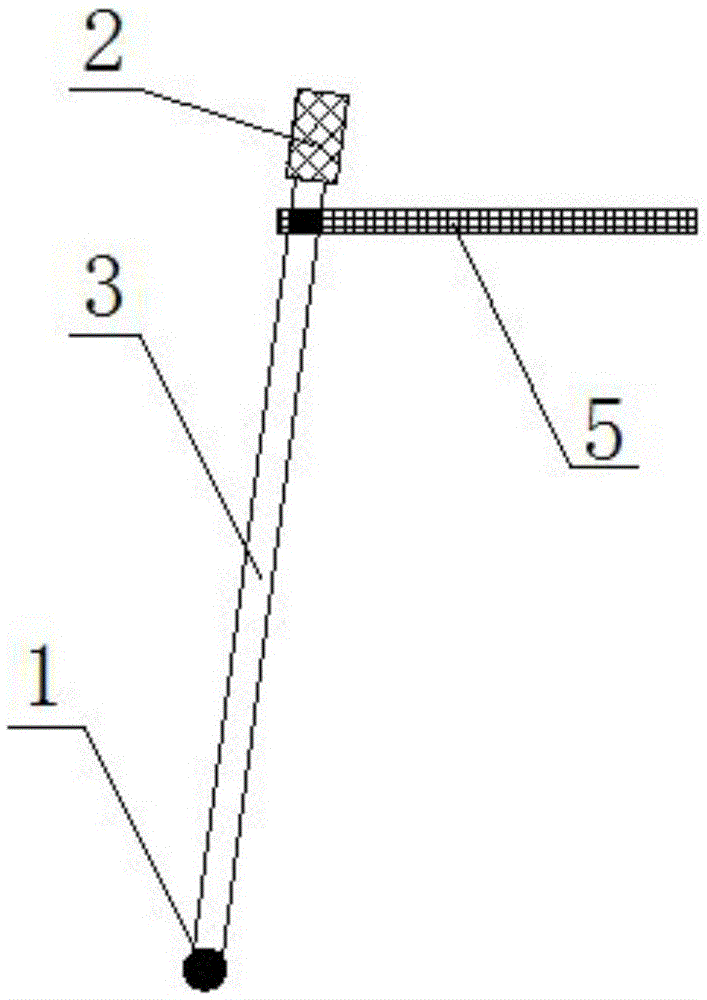

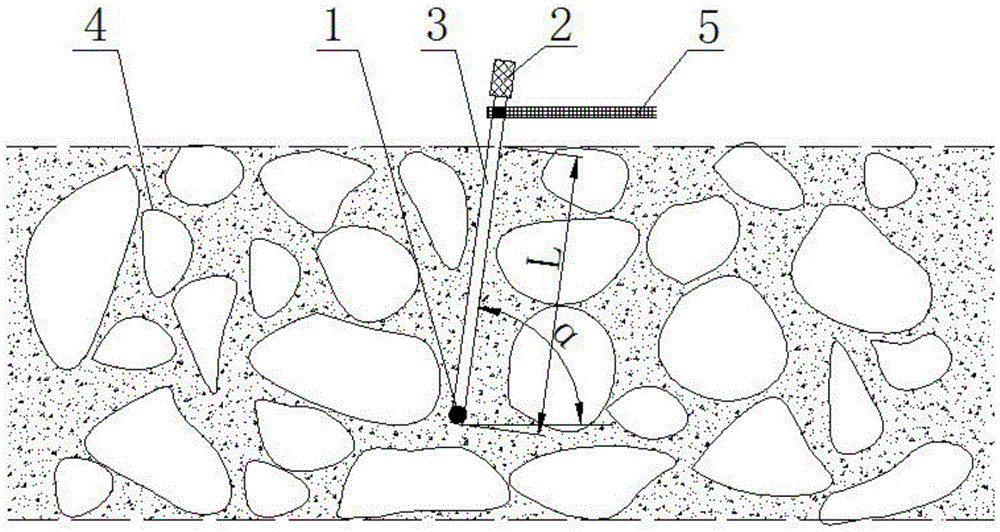

[0024] Such as figure 1 As shown, a rockfill concrete compactness detection device according to the present invention includes a test rod 3 and a fixed arm 5 sleeved on the upper part of the test rod 3, a pressure gauge 1 is installed at the lower end of the test rod 3, and a tester Instrument 2; the fixed arm 5 is parallel to the horizontal plane and is used to fix the pressure gauge 1 at the test point during testing.

[0025] Such as figure 2 As shown, using the figure 1 The method for measuring the compactness of rockfill concrete by the measuring device mainly includes the following steps:

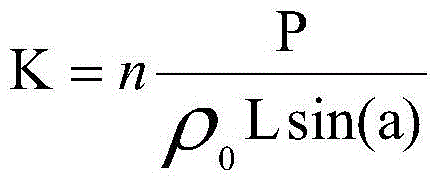

[0026] (1) After the rockfill concrete 4 has piled up the rocks, determine the test point, use the fixed arm 5 to fix the pressure gauge 1 and the test rod 3 at the test point, and measure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com