Method for measuring pH value of high-temperature high-pressure water solution

A technology of high temperature and high pressure, measurement method, applied in measurement devices, material analysis by electromagnetic means, instruments, etc., can solve problems such as unknown composition and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

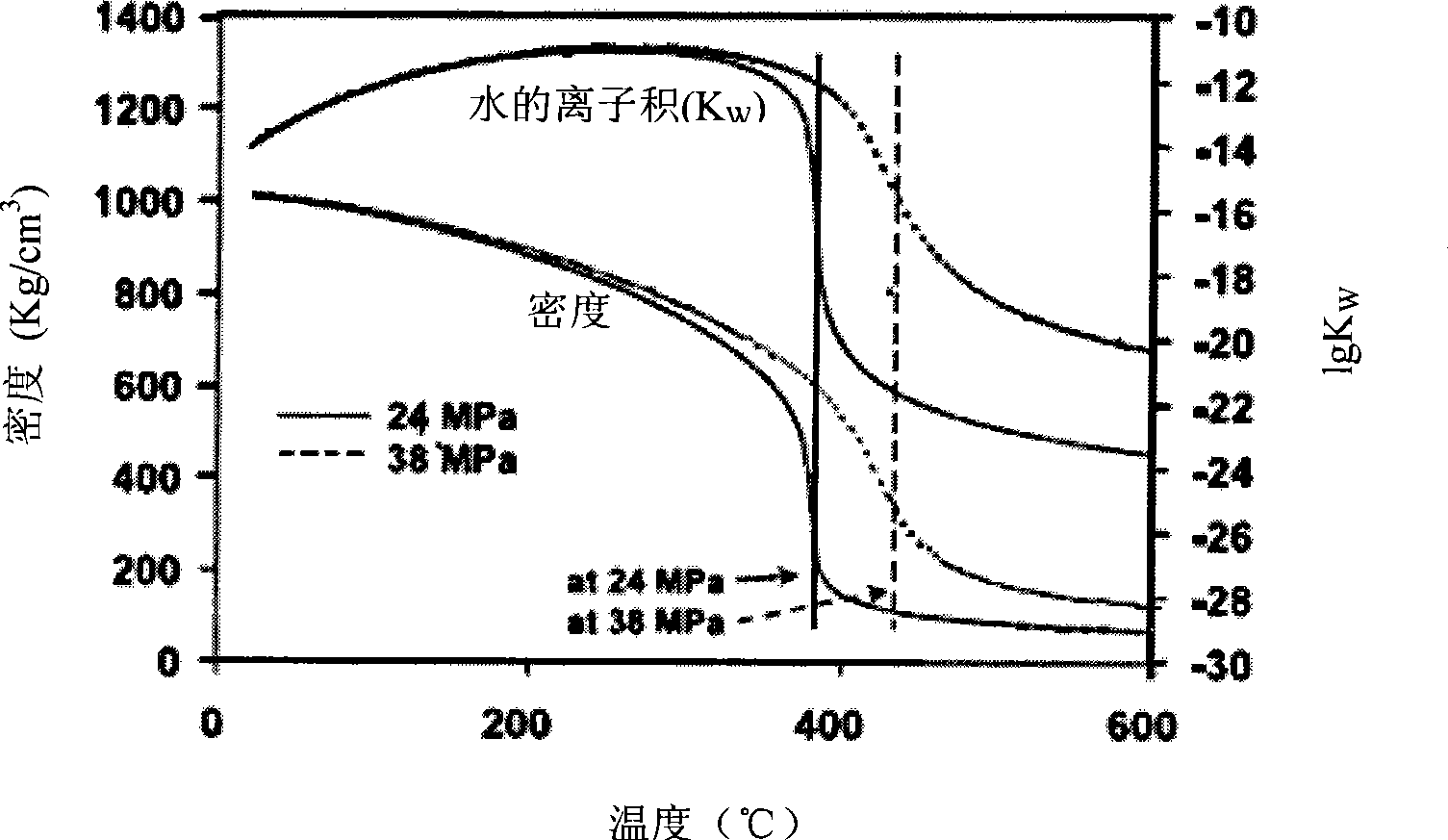

Problems solved by technology

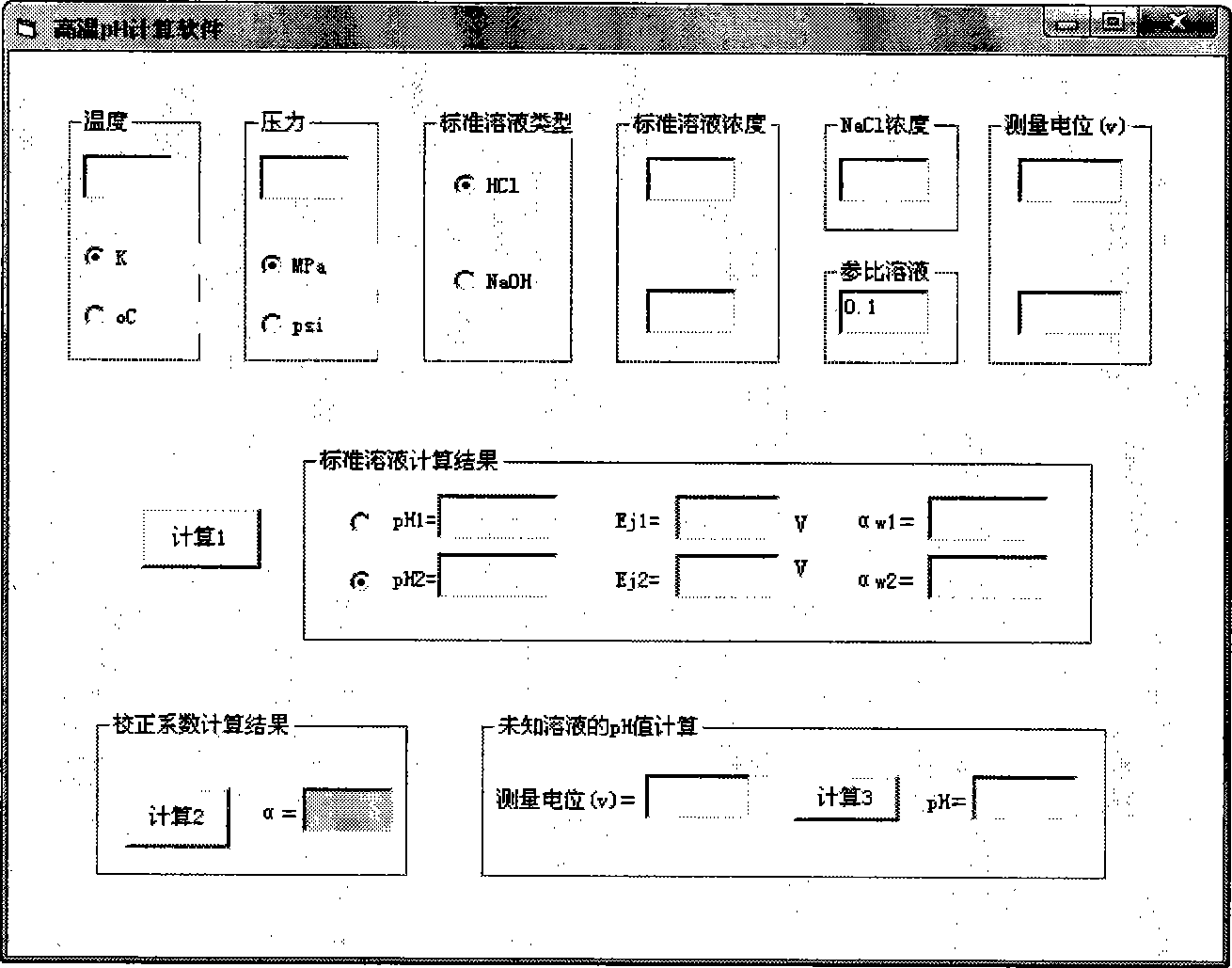

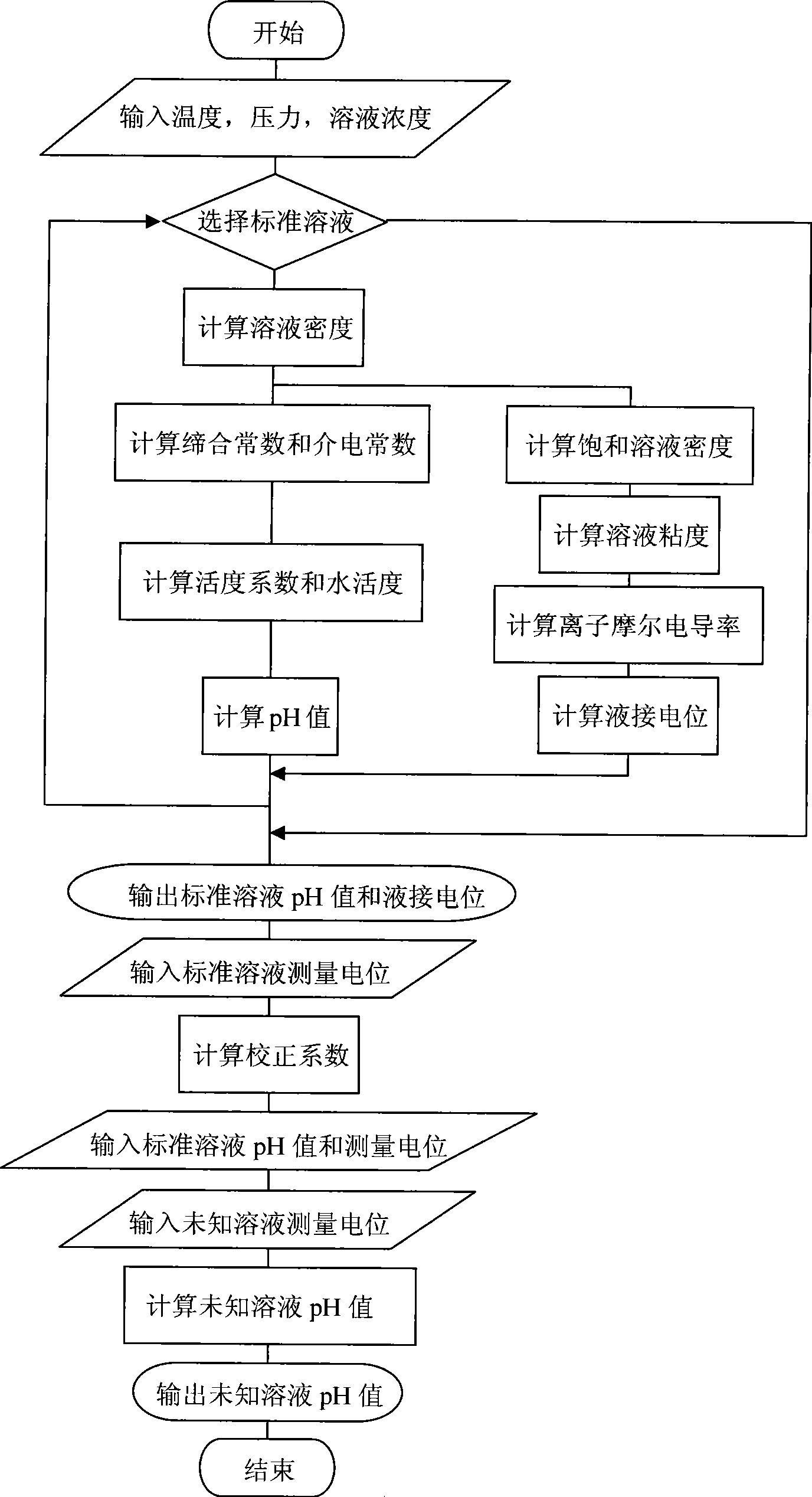

Method used

Image

Examples

Embodiment 1

[0105] Measurement of the pH value of the mixed solution of NaOH and NaCl with three concentrations at 150℃ and 7MPa

[0106] 1. Pump the standard solution 1 (0.01mol / KgNaOH+0.1mol / KgNaCl) into the autoclave, the flow rate is 1ml / min, when the temperature T=150°C and the pressure P=7MPa, measure the YSZ pH sensor in the solution relative to The potential of the reference electrode is E 1 = -0.03876v;

[0107] 2. Pump the standard solution 2 (0.1mol / Kg NaOH+0.1mol / Kg NaCl) into the autoclave, the flow rate is 1ml / min, when the temperature T=150°C and the pressure P=7MPa, measure the YSZ pH sensor in the solution The potential with respect to the reference electrode is E 2 = -0.04775V;

[0108] 3. Three solutions to be tested (0.02mol / Kg NaOH+0.1mol / Kg NaCl; 0.08mol / KgNaOH+0.1mol / Kg NaCl; 0.3mol / Kg NaOH+0.1mol / Kg NaCl) (in order to make the pH measurement result Can be compared with theoretical calculation results and GE commercial pH software calculation results and imagina...

Embodiment 2

[0114] 230℃, 28MPa, 0.01mol / Kg HCl+0.1mol / Kg NaCl solution pH value test

[0115] 1. Pump the standard solution 1 (0.001mol / Kg HCl+0.1mol / Kg NaCl) into the autoclave, the flow rate is 1ml / min, when the temperature T=230°C and the pressure P=28MPa, measure the YSZ pH sensor in the solution The potential with respect to the reference electrode is E 1 =0.186v;

[0116] 2. Pump the standard solution 2 (0.1mol / Kg HCl+0.1mol / Kg NaCl) into the autoclave, the flow rate is 1ml / min, when the temperature T=230°C and the pressure P=28MPa, measure the YSZ pH sensor in the solution The potential with respect to the reference electrode is E 2 =0.311v;

[0117] 3. The solution to be tested is 0.01mol / Kg HCl+0.1mol / Kg NaCl (an imaginary acidic unknown solution to be tested in order to make the pH measurement result can be compared with the theoretical calculation result and the calculation result of GE commercial pH software) into the autoclave , when the flow rate is 1ml / min, the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com