Device and method for in situ characterization of quality parameters and/or properties of inorganic binder systems

A technology of inorganic adhesives and adhesive systems, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems such as large errors and expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

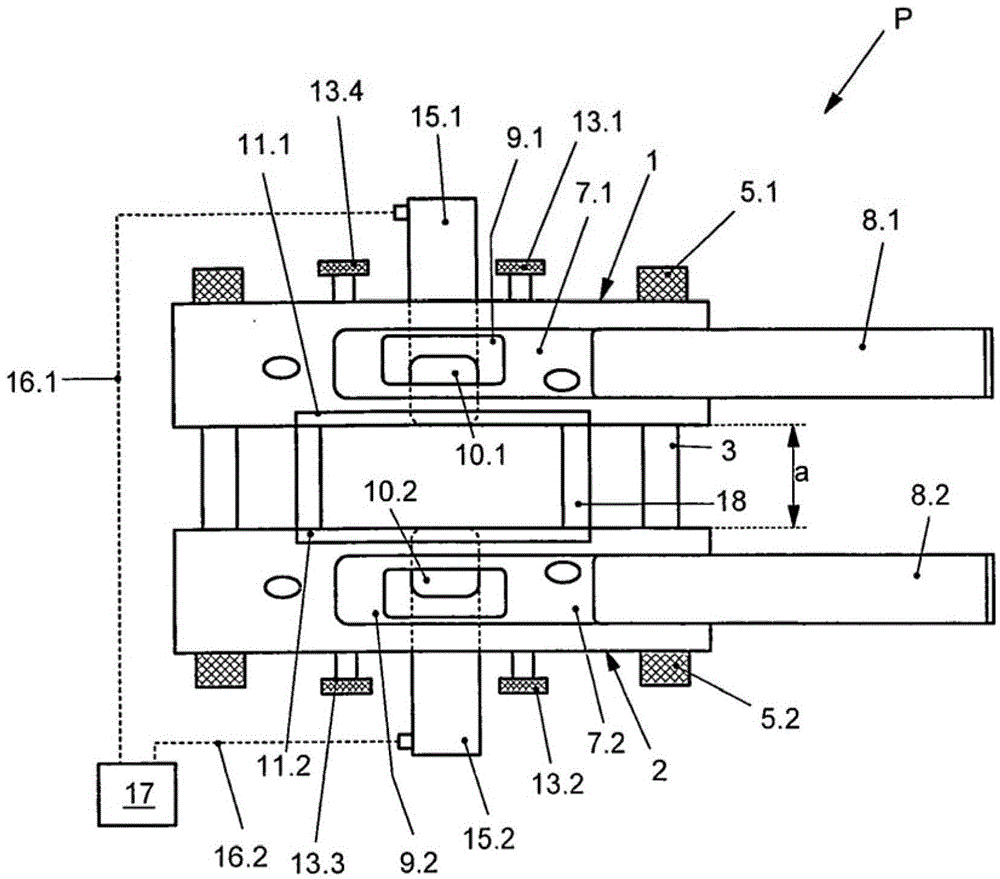

[0027] according to figure 1 , the device P according to the invention for the in situ description of quality parameters and / or properties of inorganic binder systems has two walls 1 and 2 which are arranged at a distance a apart. This distance a is determined by the stop sleeves 3 which are pushed onto the bolts 4 in each case. Four screws 4 of this type pass through the walls 1 and 2 in each case, knurled nuts 5 . 1 and 5 .

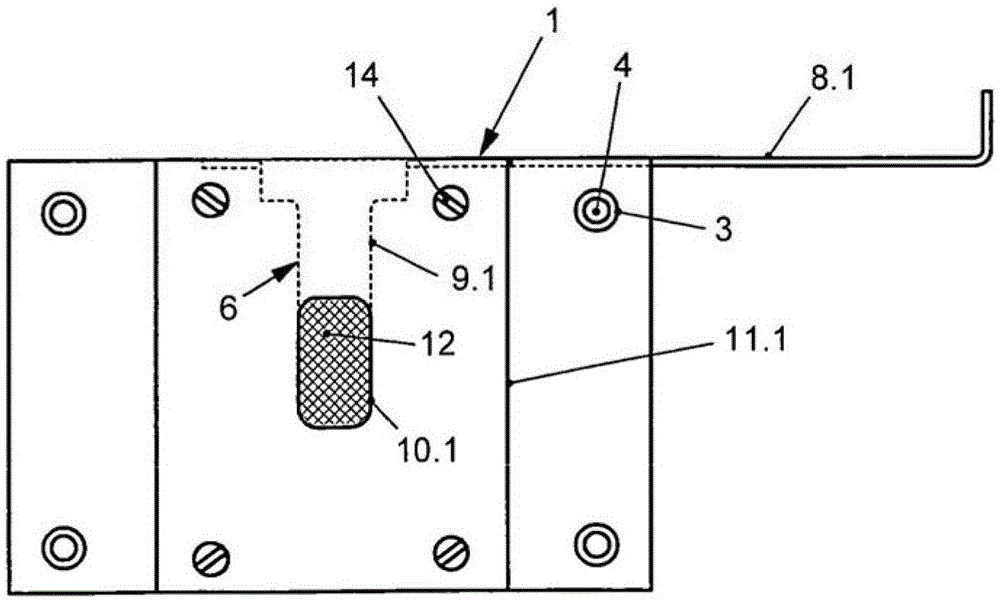

[0028] Each wall 1 and 2 respectively has a figure 2 The step-shaped recess 6 is shown in dashed lines and can be seen. Viewed from above, the first part of the stepped recess 6 is designed as a flat guide 7.1 or 7.2 for the slide 8.1 or 8.2. With this slide 8.1 or 8.2, the stepped recess 6 can be closed off as a whole.

[0029] A funnel-shaped well 9.1 or 9.2 adjoins the flat guide 7.1 or 7.2, which leads into the oval cavity 10.1 or 10.2. The elliptical cavity 10.1 or 10.2 also opens out through the walls 1 and 2 in this elliptical shape and eve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com