Identification method and equipment of compressive strength of rock and rotary rock drilling method

A technology of compressive strength and identification equipment, which is applied in the direction of earthwork drilling, drilling equipment, drilling automatic control system, etc., and can solve the problem of being unable to effectively identify the compressive strength of the rock to be broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

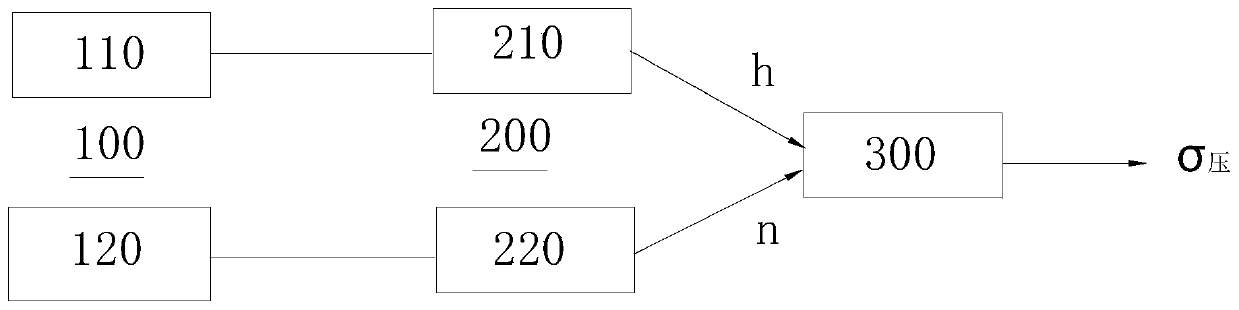

[0042] According to an embodiment of the present invention, the rotary drilling device 100 includes a drill bit with a circular rock fracture surface, where P is the pressure output by the rotary drilling device 100, and M is the output pressure of the rotary drilling device 100. The output torque of 100, h is the depth that the drill bit drills into the rock within the predetermined time t, n is the number of circles that the drill bit rotates within the predetermined time t, μ is the friction coefficient between the drill bit and the rock, A is the cross-sectional area of the drill bit.

[0043] Among them, W=2πM+Ph / n, W1=σ 压 Ah / n, Combined with energy conservation W=W1+W2, the control device 300 can be based on the formula Calculate the compressive strength σ in compression.

[0044] According to another embodiment of the present invention, the rotary drilling device 100 includes a barrel drill, wherein, P is the pressurizing force output by the rotary drilling devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com