Device and method for detecting keyboard defects

A defect detection and keyboard technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of simple hardware, detection is greatly affected by external light sources, manual processing of keyboard characters, etc., and achieves wide application range and software The rapid effect of the detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

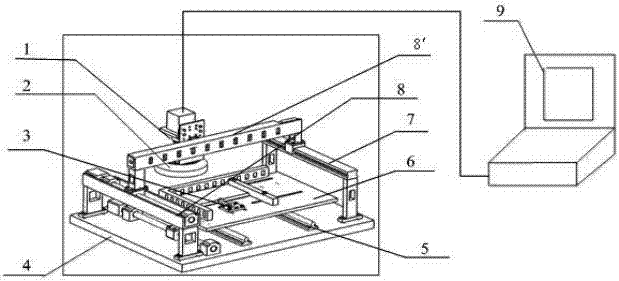

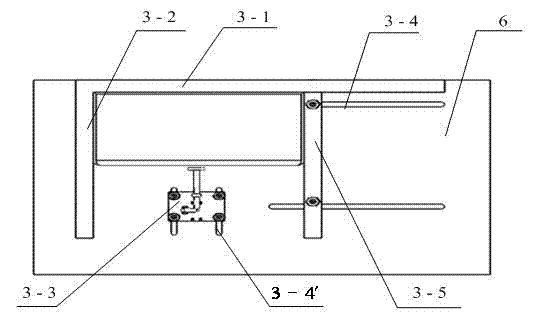

[0022] Embodiment 1: Reference figure 1 and figure 2 , the keyboard defect detection device, including camera (1), light source (2), keyboard fixing device (3), base (4), round rod guide rail (5), tray (6), linear guide rail (7), longitudinal ball screw (8), horizontal ball screw ( ) and computer (9). Two bases are fixedly installed on the left and right edges of the base (4), and two round bar guide rails (5) are installed in parallel in the middle; the camera (1) is located above the light source (2), and both are fixed on the horizontal ball screw ( ) to form a left and right moving pair; the longitudinal ball screw (8) and the linear guide (7) are respectively located on the base of the left and right edges, and the horizontal ball screw ( ) are respectively screwed with the longitudinal ball screw (8) through nuts and slipped with the linear guide (7) to form a longitudinal movement pair. The keyboard fixing device (3) is installed on the tray (6), and the tray (...

Embodiment 2

[0026] Embodiment 2: The camera adopts a 500-megapixel industrial camera and is placed above the light source (2). There is a camera hole on the light source (2). Moving the camera through the hole can ensure that the entire area of the keyboard image can be extracted. In order to ensure uniform illumination, LED ring light source should be used. The collected images are transmitted between the camera and the computer through the USB communication interface.

[0027] The positioning accuracy requirement of the keyboard fixing device (3) means that the rotation angle is kept within the range of 1 degree, and at the same time, the movement accuracy of 2.5 mm is guaranteed in the horizontal and vertical directions.

[0028] In order to facilitate the placement of the keyboard, when the tray (6) moves to the end point on the round bar guide rail (5), a part can protrude beyond the range covered by the base (4).

Embodiment 3

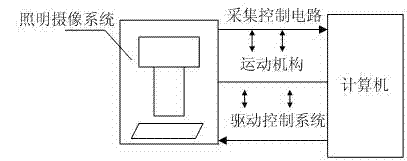

[0029] Embodiment three: as Figure 4 , this keyboard character defect detection method adopts above-mentioned device to detect, and the step of detection is as follows:

[0030] 1) Image preprocessing. The preprocessing includes grayscale, binarization and filtering processing, the purpose is to remove irrelevant pixels and highlight the difference between the keyboard characters and the background;

[0031] 2) Obtain the region of interest: Use mathematical morphology to obtain the entire region of interest. First, the expansion operation is used to obtain the approximate area of the character; then, the closed operation is performed to remove some small holes in the character area to prevent it from interfering with the image area. Acquisition; finally, an opening operation is performed to ensure that there can only be one character area on a keycap, and then edge extraction is performed to obtain the entire area;

[0032] 3) Tilt correction: first calculate the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com