Coating device and coating film forming system

A coating device and coating film technology, which is applied to the surface coating liquid device, coating, electrode rolling/calendering, etc., can solve the problem that the coating position of the coating film cannot be consistent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

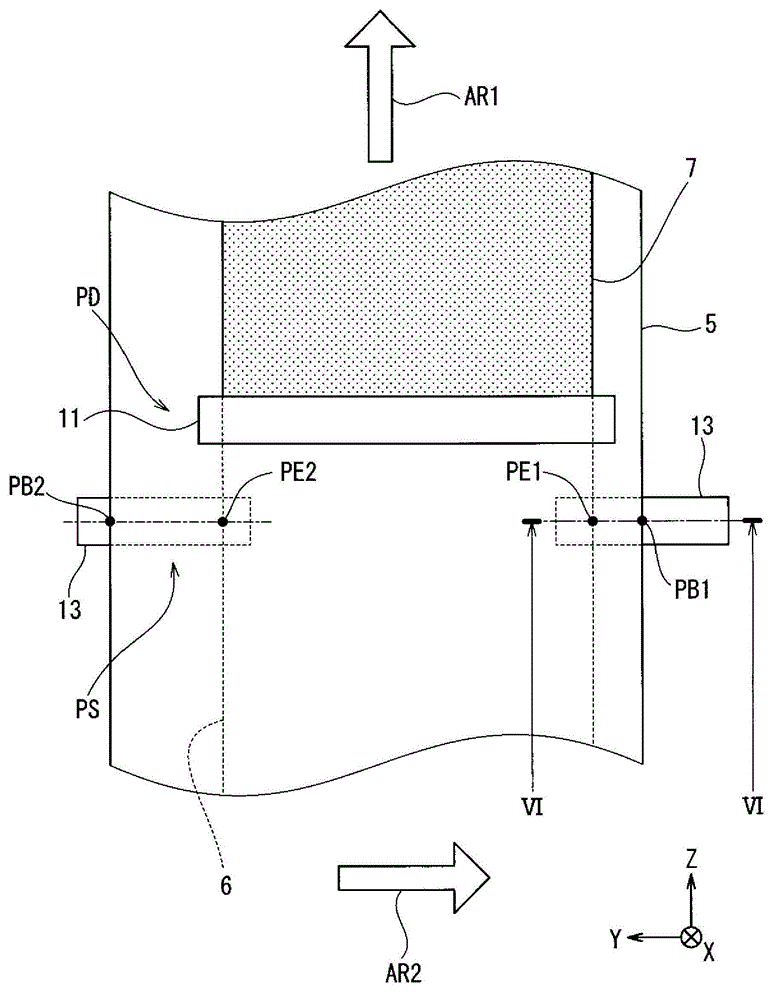

[0026] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0027]

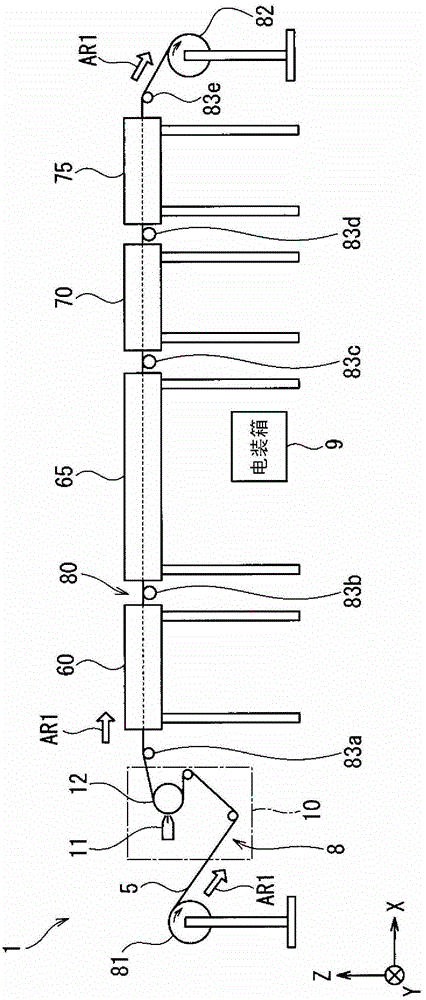

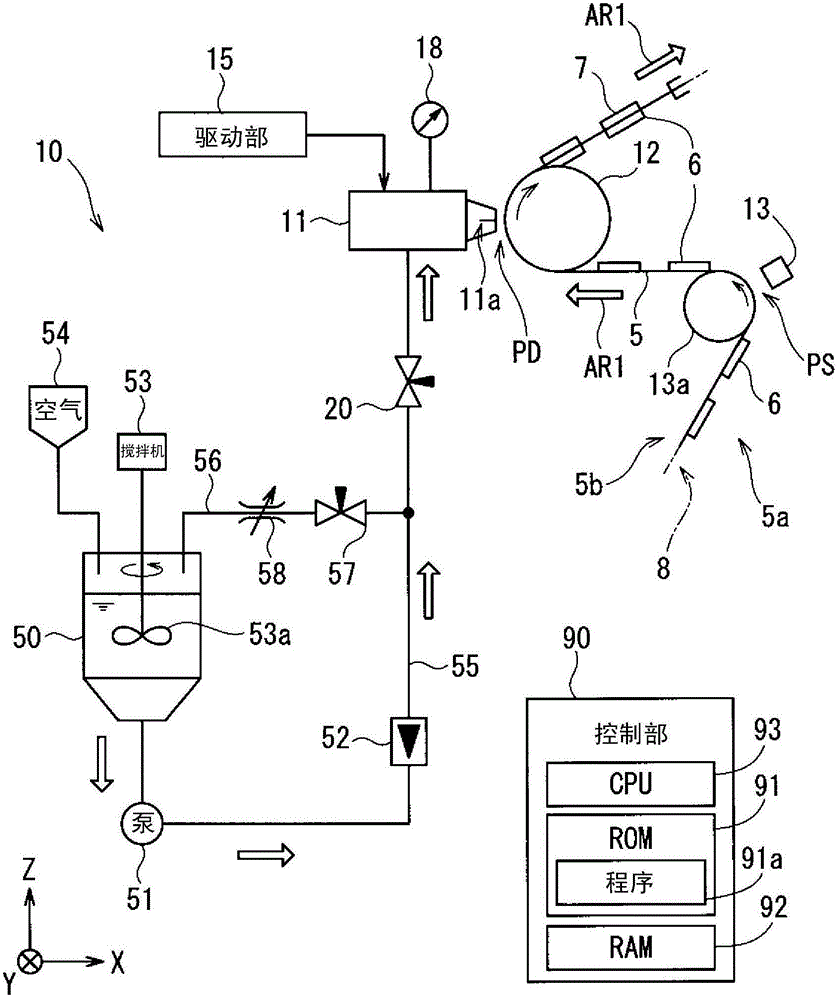

[0028] figure 1 It is a figure which shows the whole structure of the coating film forming system 1 which incorporates the coating apparatus of this invention. In addition, in figure 1 In each of the following figures, in order to clarify the direction relationship, the XYZ rectangular coordinate system is marked, the Z-axis direction is taken as the vertical direction, and the XY plane is taken as the horizontal plane. In addition, in figure 1 In each of the following figures, the size and number of each part are enlarged or simplified as necessary for easy understanding.

[0029] The coating film forming system 1 forms a coating film of an active material on a base material 5 and dries the formed coating film, thereby manufacturing an electrode of a lithium ion secondary battery. Such as figure 1 As shown, the coating film forming system 1 ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com