Method of manufacturing electron-emitting device, electron source, and image display device

一种图像显示装置、电子发射的技术,应用在放电管/灯的制造、电气元件、电极系统制造等方向,能够解决元件电子发射特性降低、元件破坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

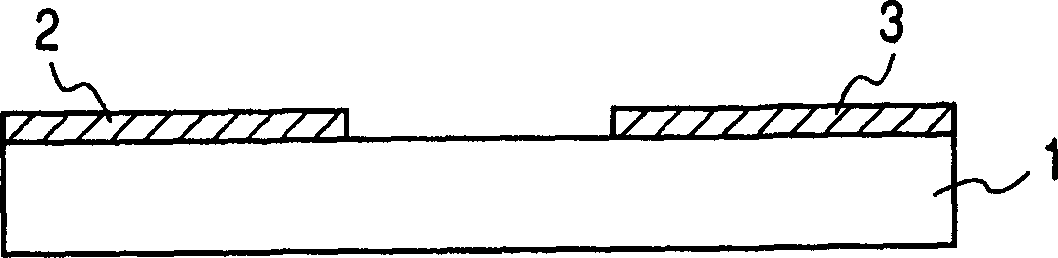

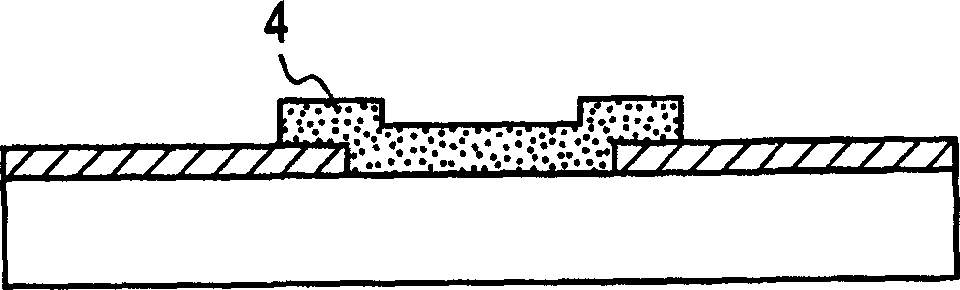

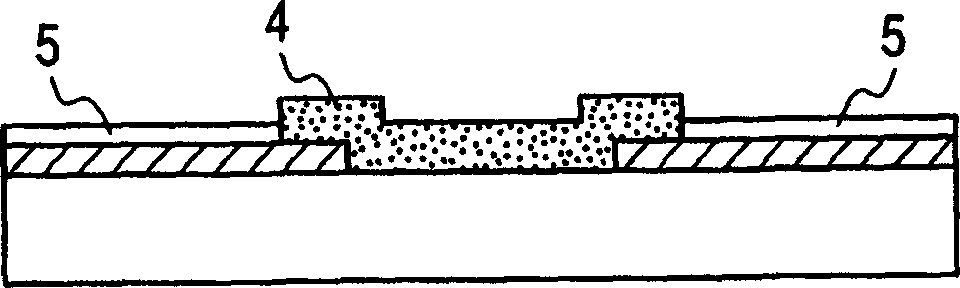

[0083] A PD200 (glass substrate) used in a plasma display was used as a substrate, and Pt with a film thickness of 0.5 μm was deposited by sputtering and photolithography to form a plurality of electrode pairs. After that, use Ag-based photosensitive paste to form a film by screen printing, dry it at a temperature of about 100°C, expose it using a mask, perform a wet development process, and sinter it at a weak temperature of 500°C to make a film thicker. Column wiring around 8μm. In addition, using a PbO-based (lead glass) photosensitive paste, the same method as the above-mentioned column wiring process was performed three times to form a film / dry / exposure / development / sintering process, and finally an insulating layer with a film thickness of about 30 μm was obtained. In addition, row wiring is formed on the insulating layer by Ag-based screen printing method and sintering at about 430°C. Thereafter, a Pd-based organic solvent was discharged by an inkjet method to form an i...

Embodiment 2

[0086] As in Example 1, after forming a plurality of electrode pairs, wiring lines, and a conductive film on a glass substrate, an antistatic film was formed on the entire substrate when the conductive film remained. The antistatic film is to be made on the SnO x A solution in which microparticles doped with antimony and the like are dispersed in a mixture of isopropanol (IPA) and ethanol is applied by sputtering, dried and sintered at 250°C.

[0087] Thereafter, in the same manner as in Example 1, the cleaning process was performed while changing the hydraulic pressure, and the effect of foreign matter removal was confirmed. The method of confirmation is to compare with the method of counting the number of foreign substances larger than about 1 μm with an electron microscope. The results are shown in Figure 7 . Figure 7 The vertical axis of is the number of foreign matter per unit area. Compared with the case where the cleaning process is not performed, when the cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com