In-mould automatic-shearing pouring gate mechanism

A gate, automatic technology, applied in the field of automatic shear gate mechanism in the mold, can solve the problems of wasting manpower and equipment, and the cutting place is not beautiful, and achieves the effect of beautiful cutting and cutting, saving manpower and equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

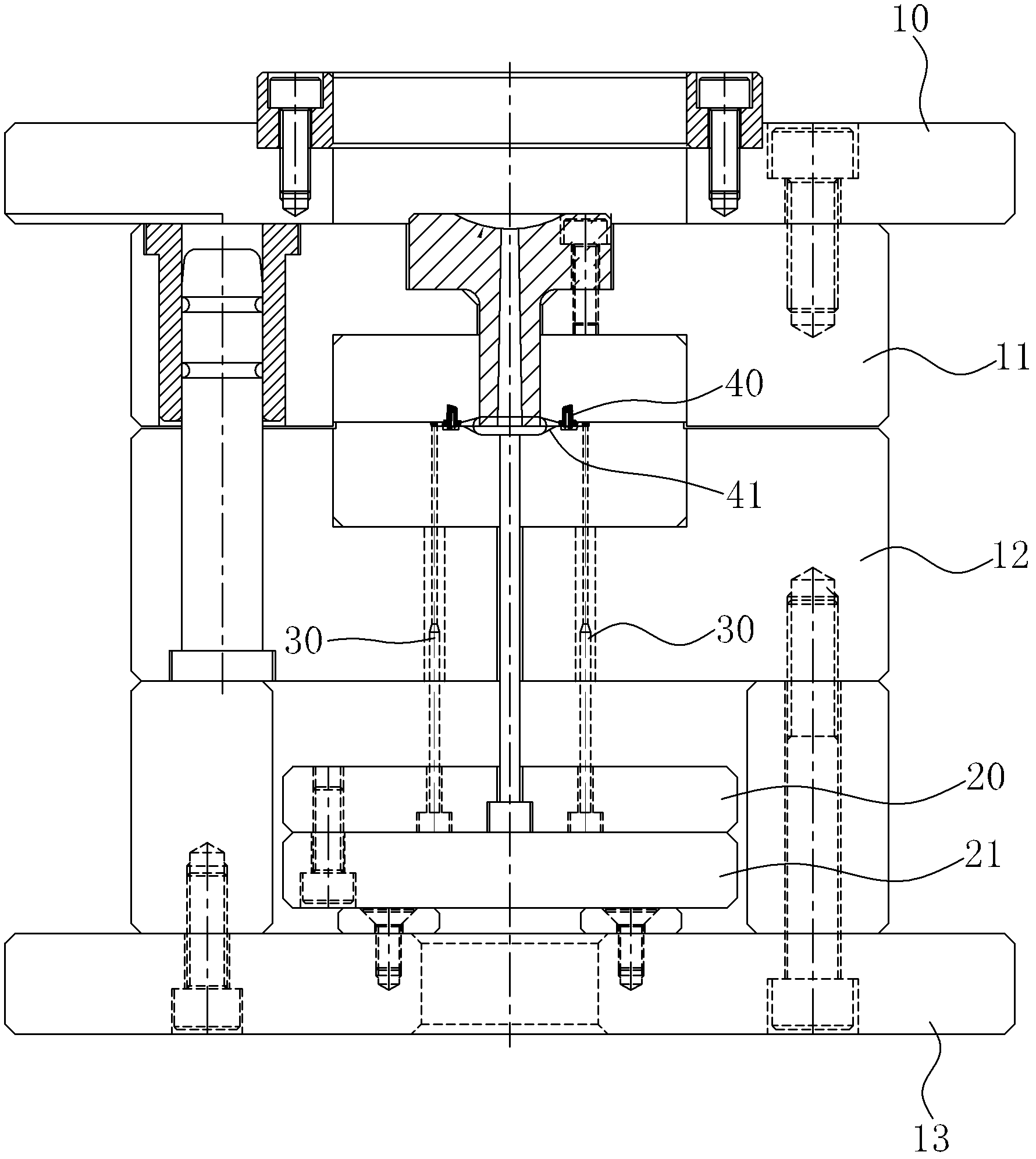

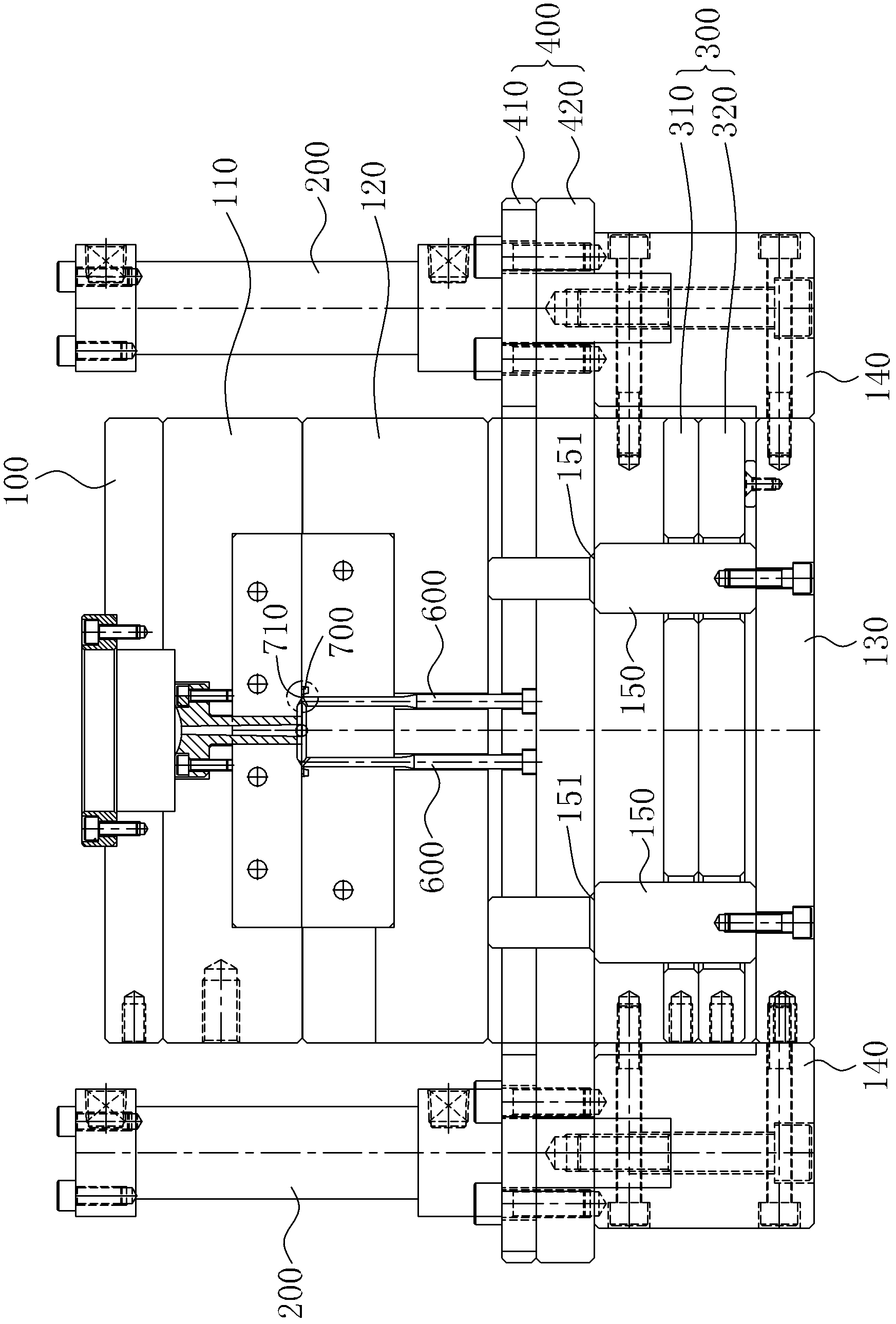

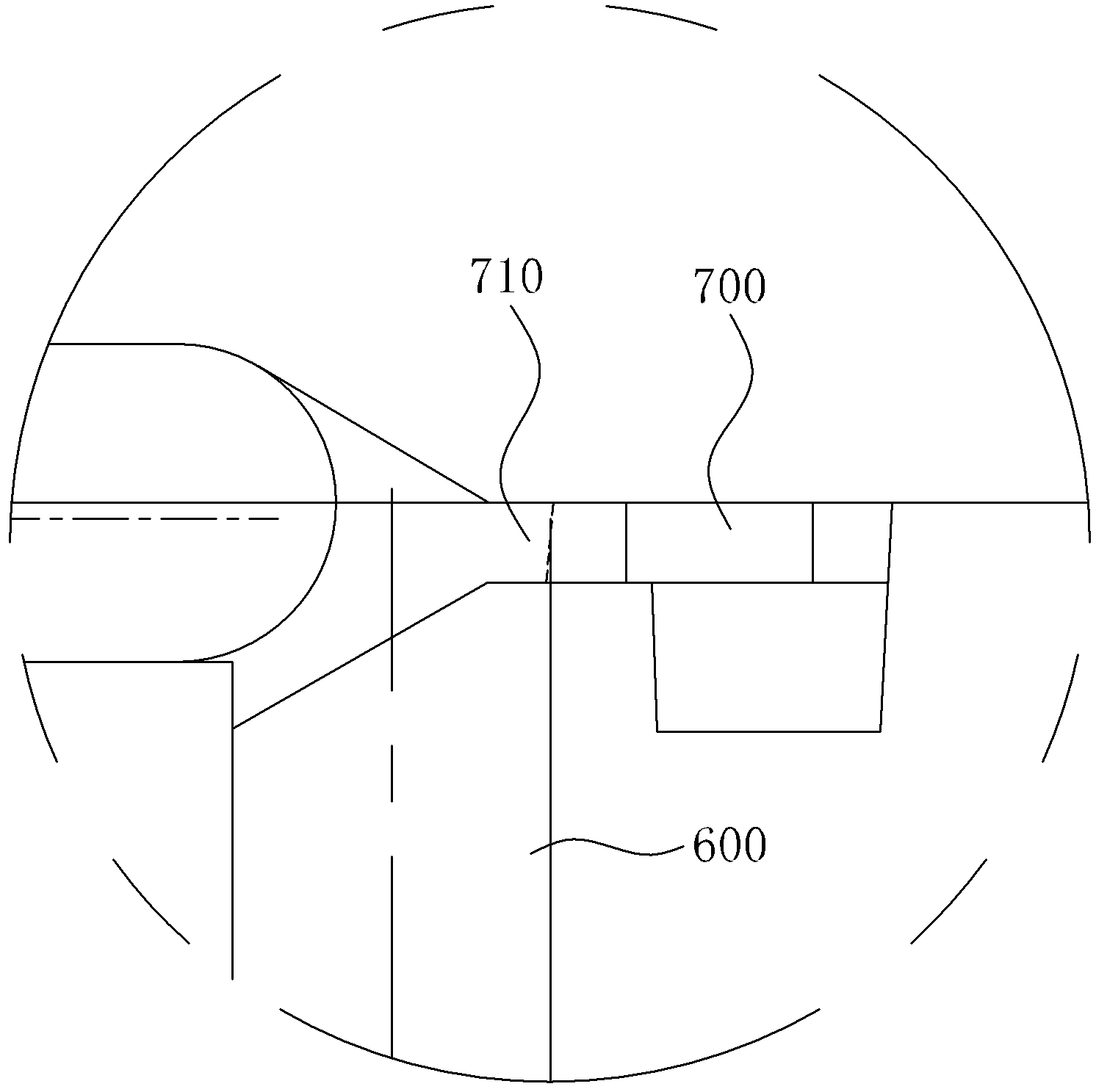

[0018] see figure 2 , image 3 As shown, the in-mold automatic shearing gate mechanism of the present invention is applied in a mould. state, the automatic shear gate mechanism in the mold includes:

[0019] Hydraulic cylinder 200, which is located on both sides of the mold and is fixedly connected with the foot pads 140 on both sides of the mold by screws;

[0020] The first ejector plate 300, which is located above the lower fixing plate 130, the first ejector plate 300 includes a first upper ejector plate 310 and a first lower ejector plate 320, and on the first ejector plate 300 An ejector pin is fixed to eject the product 700;

[0021] The second ejector plate 400 is located above the first ejector plate 300, the second ejector plate 400 is connected to the hydraulic cylinder 200, the second ejector plate 400 includes a second upper ejector plate 410 and The second lower ejector plate 420, the hydraulic cylinder 200 drives the second ejector plate 400 to eject and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com