Combined structure of combination fan

A combination of structure and fan technology, applied to parts of pumping devices for elastic fluids, liquid fuel engines, non-variable pumps, etc., can solve the problem of poor applicability of integrated fans, hindering the transmission and assembly of fan air volume Inconvenience and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the accompanying drawings.

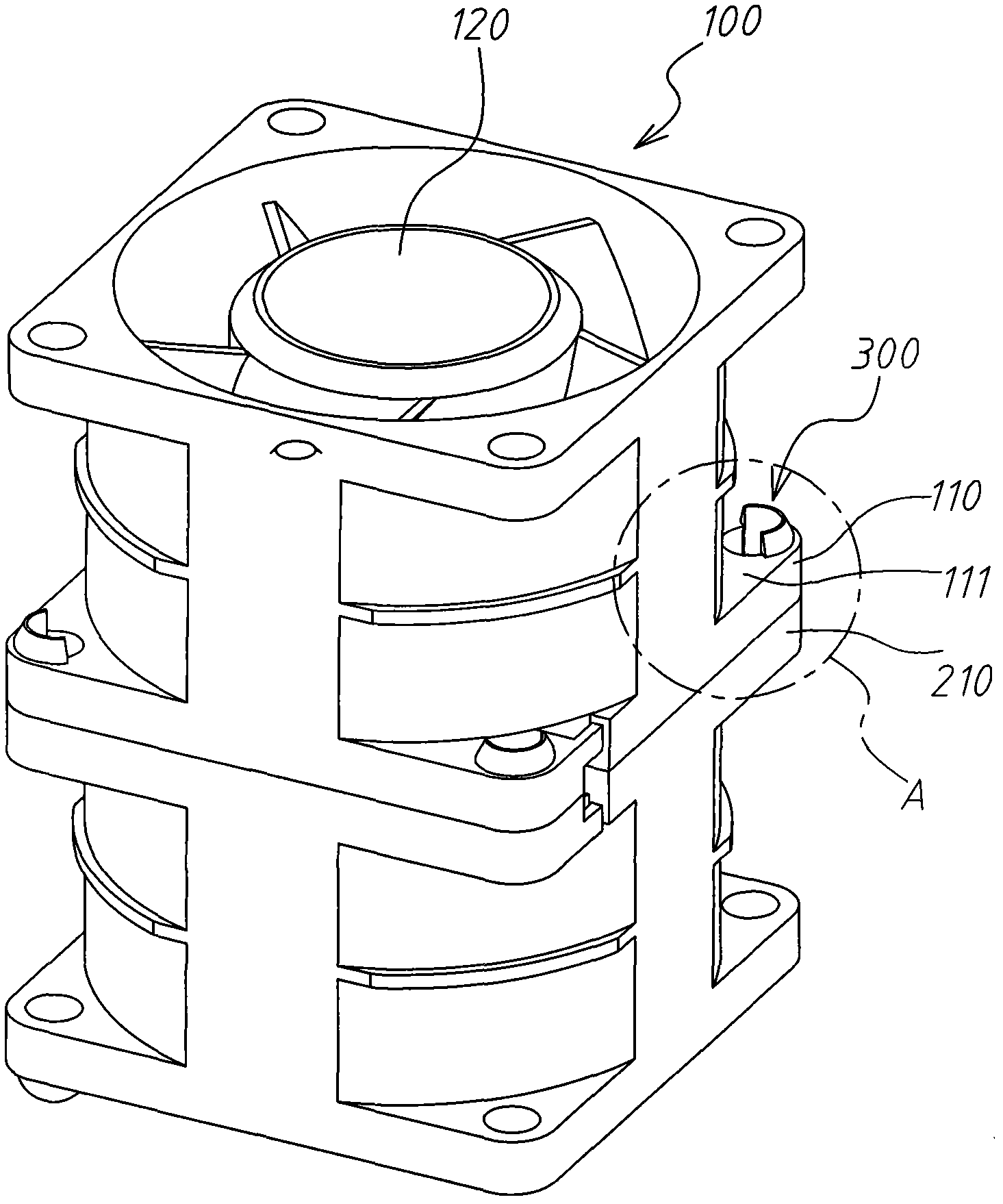

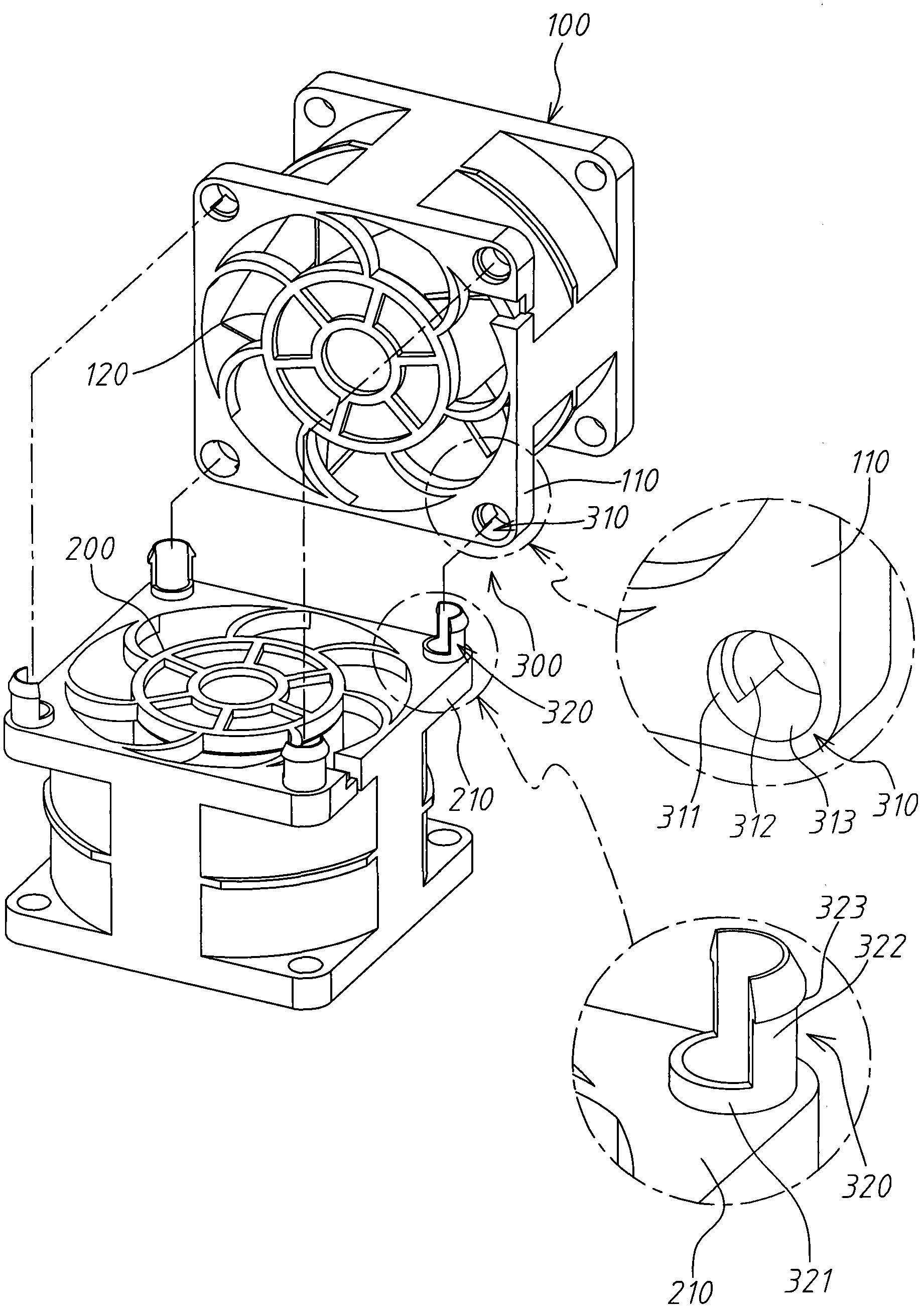

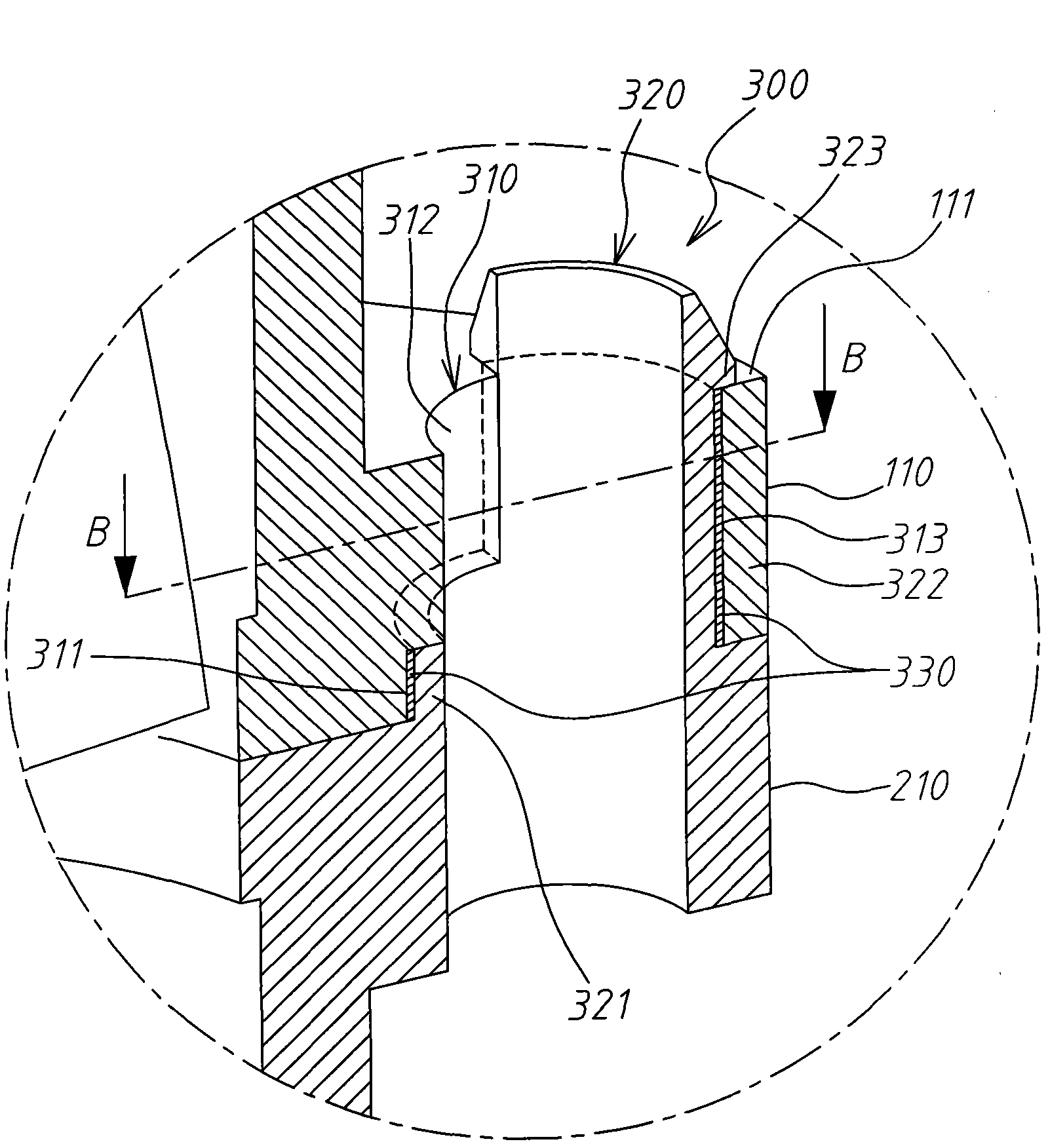

[0028] see Figure 1 to Figure 4 , which respectively show an appearance view, an exploded view, a longitudinal sectional view, and a transverse sectional view of the combined structure of the integrated fan according to an embodiment of the present invention. As shown in the figure, the combination structure of the integrated fan according to an embodiment of the present invention is used to combine two fans as a first fan 100 and a second fan 200. The combination structure 300 includes four combination holes 310, and The four combining holes match the four combining posts 320 of corresponding configuration, and the adhesive layer 330 is glued between the combining holes and the combining posts.

[0029] The size of the first fan 100 is, for examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com