Applicator ram having a ram adaptor

An adapter and applicator technology, applied in the direction of circuit/collector parts, electrical components, connections, etc., which can solve the limitation of crimp height adjustment dial placement, difficulty in supplying the end of the terminator punch, and small dial size. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

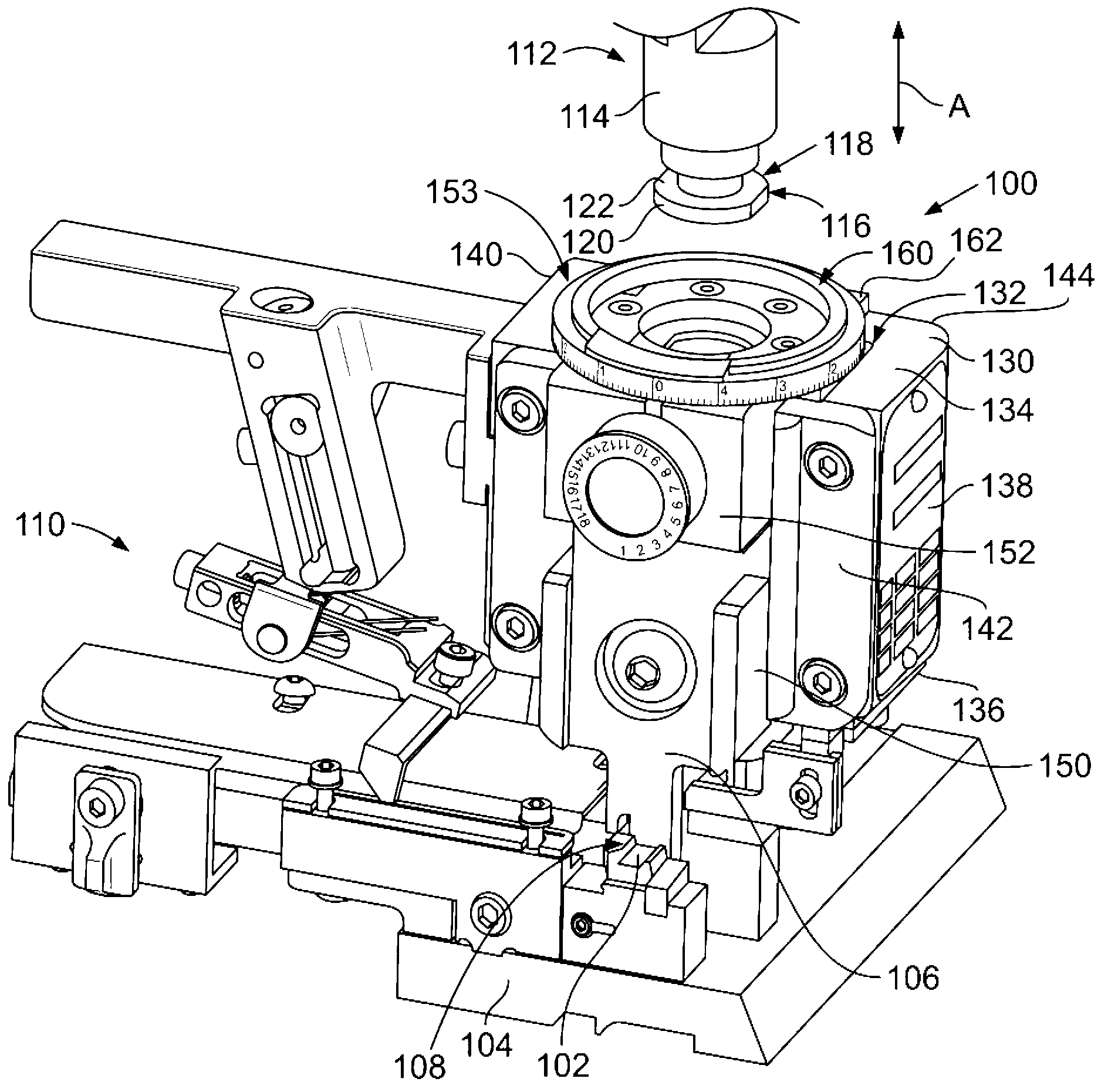

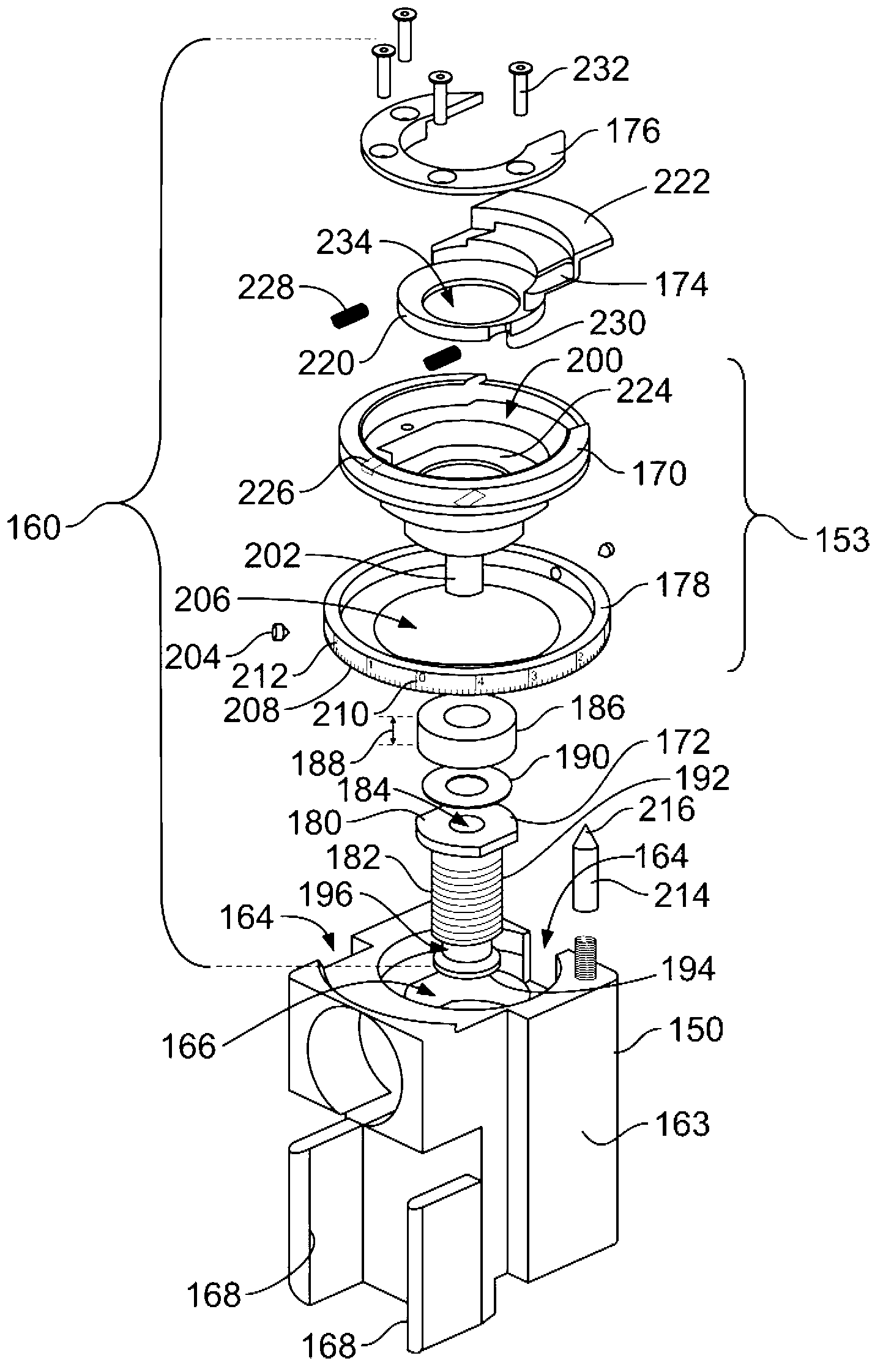

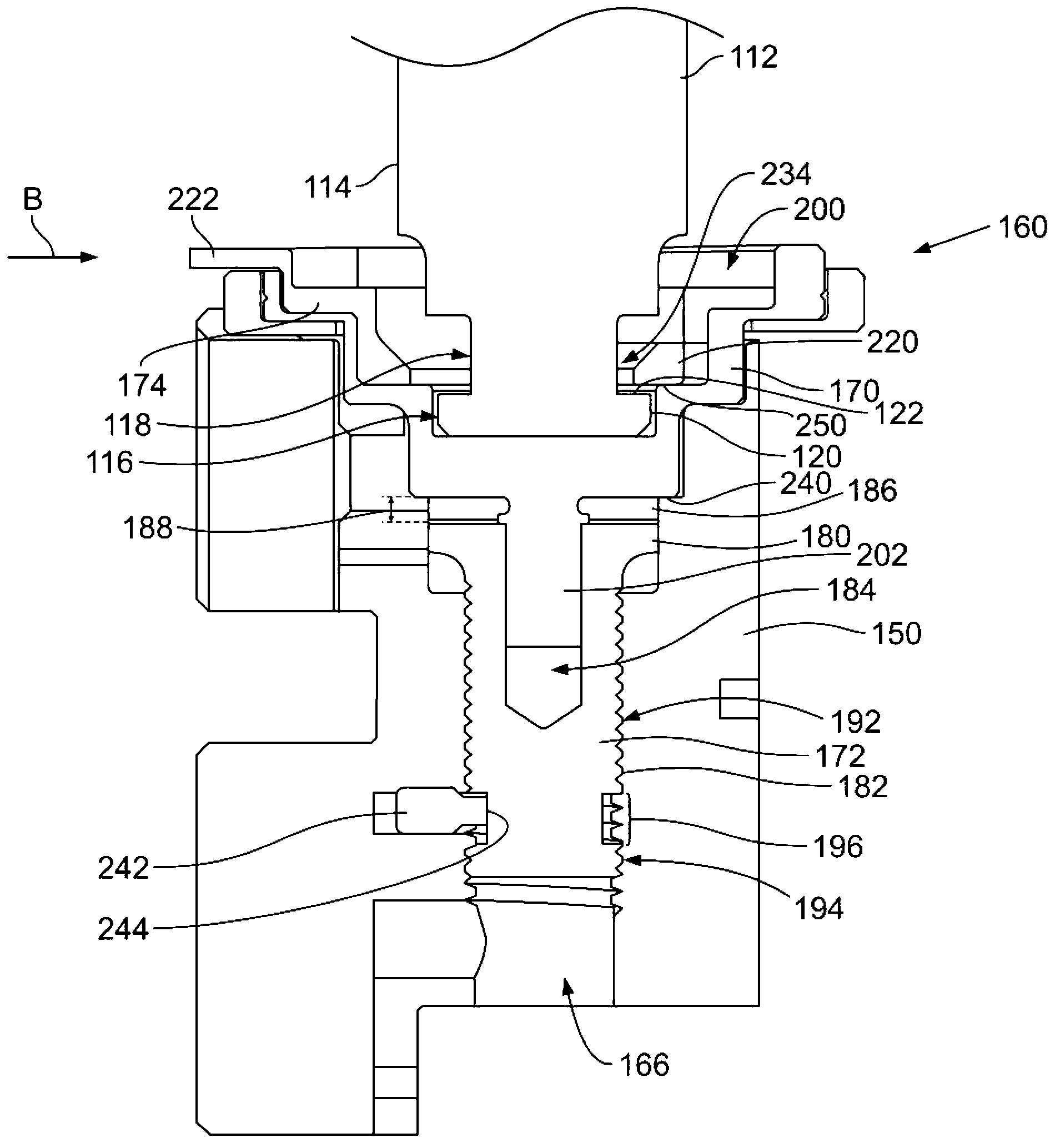

[0009] figure 1 is a front perspective view of an applicator 100 formed in accordance with an exemplary embodiment. The applicator 100 is used to crimp a terminal to the end of an electrical wire. The applicator 100 includes an anvil 102 secured in place on a base 104 supporting the applicator 100 . The applicator 100 includes a crimping tool 106 that is driven toward and away from the anvil 102 along a crimping stroke to crimp the terminal to the wire. A crimping region 108 is defined between the anvil 102 and the crimping tool 106 . The terminals are crimped to the wires within the crimp area 108 . In an exemplary embodiment, the applicator 100 includes a feeder 110 that feeds the terminals to the crimping area 108 during the crimping process.

[0010] In an exemplary embodiment, the applicator 100 is configured to be coupled to a terminator ram 112 of a terminator or termination machine (not shown). The terminator punch 112 is driven through the termination stroke by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com