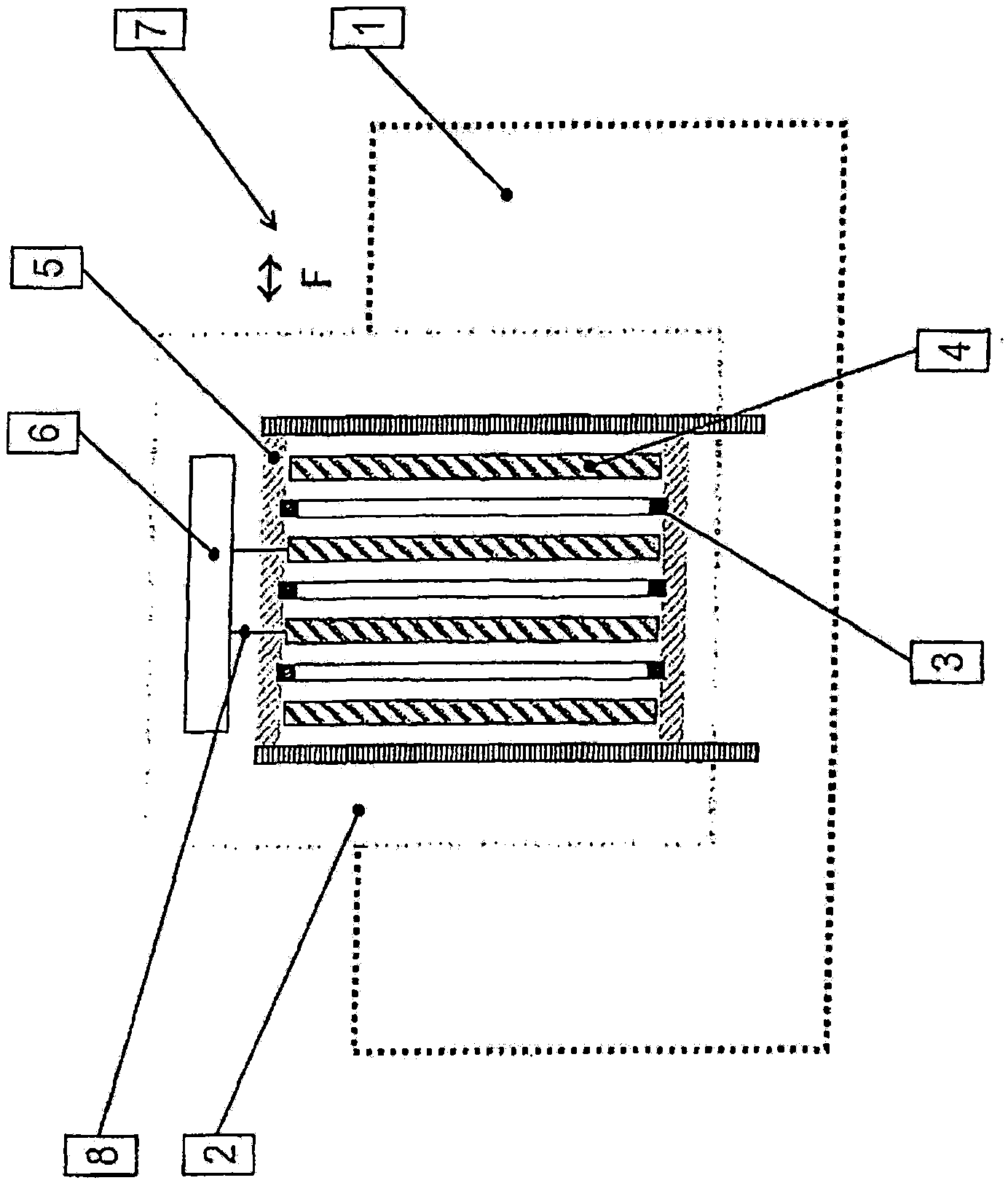

Spark gap with a plurality of single spark gaps connected in series in a stacked arrangement

A technology of single spark gap and series connection, applied in the field of spark gap, can solve the problems of rising protection level, insufficient thermal coupling of protection devices, short circuit of separation gap, etc., and achieve the effect of residual voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

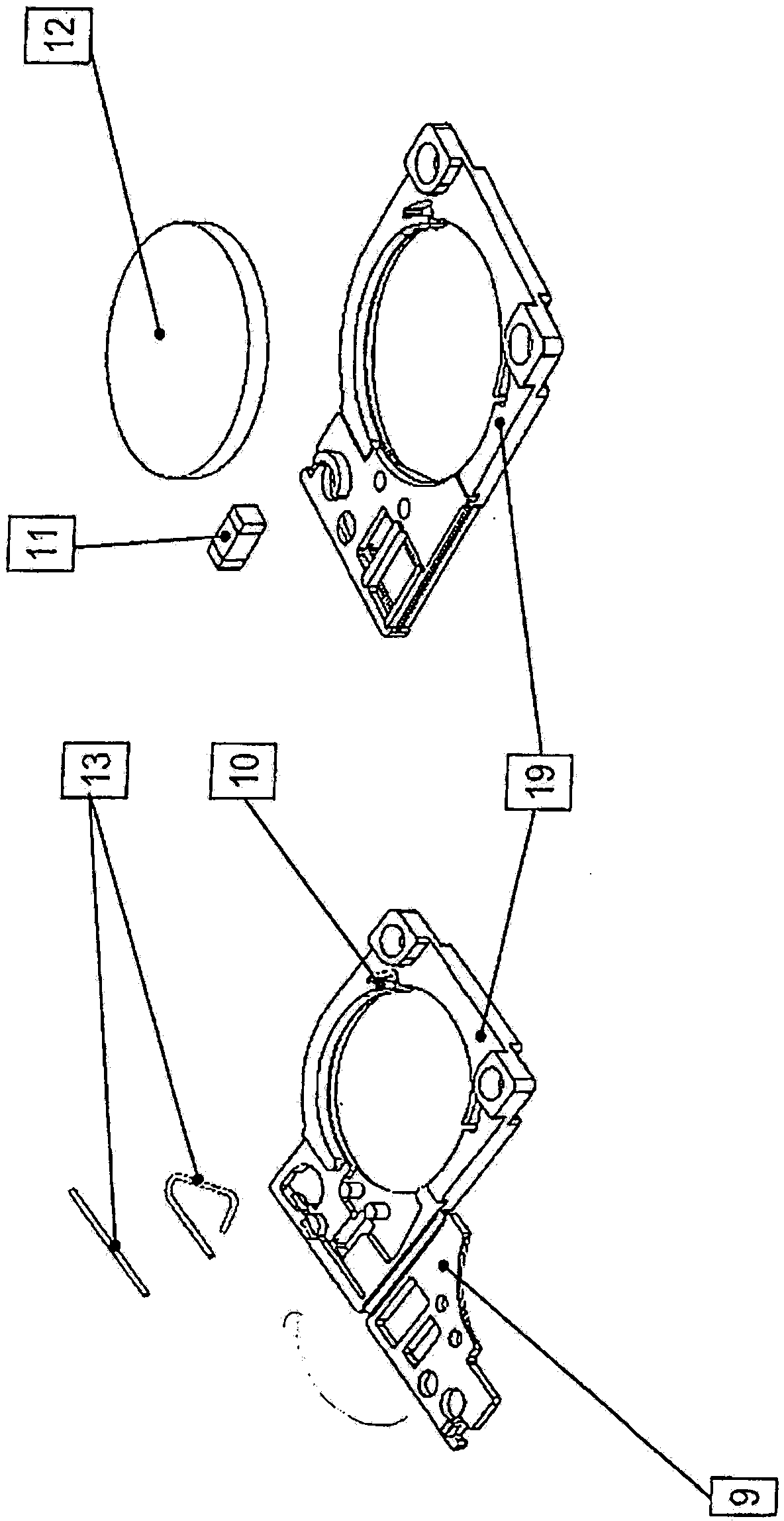

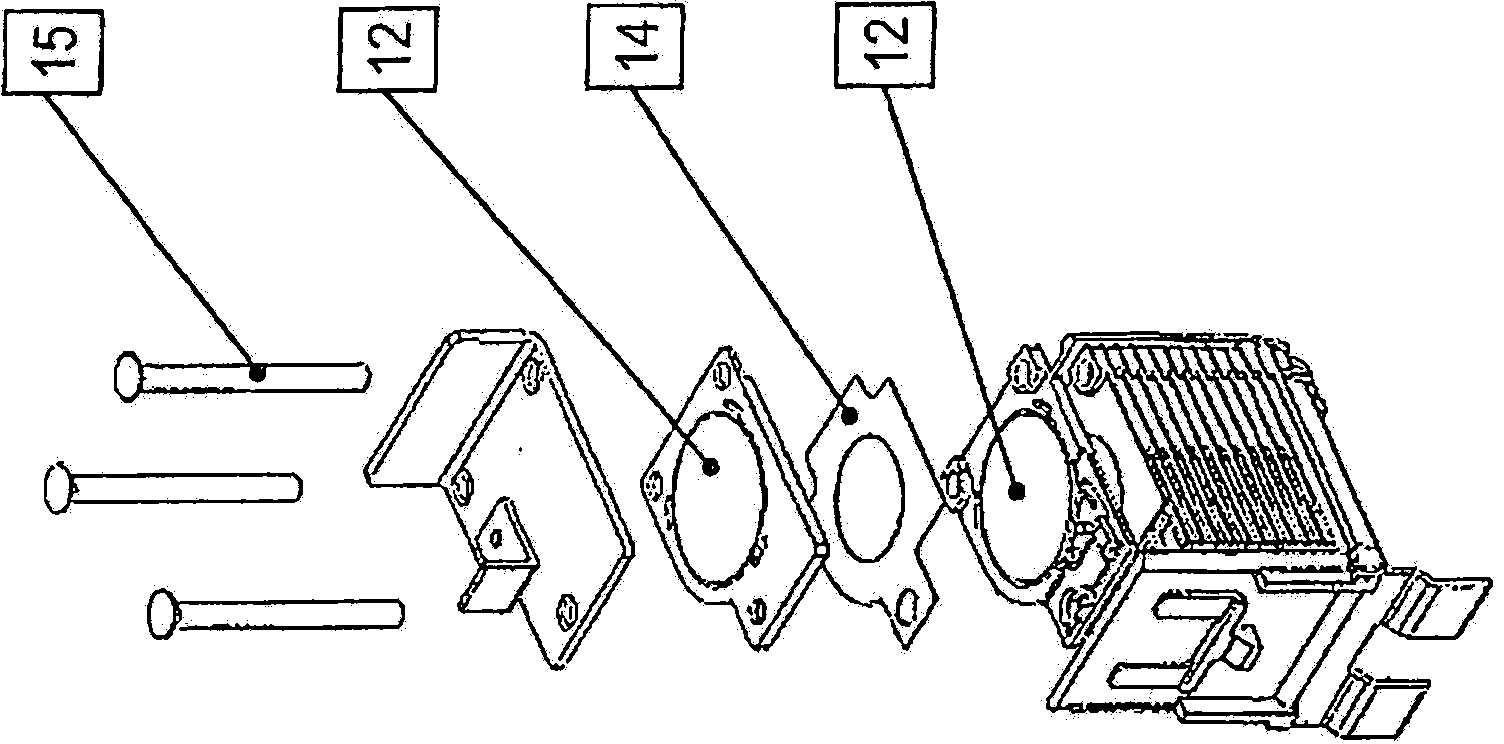

[0058] In order to eliminate the disadvantages of the prior art, an aging-resistant lightning current arrester is proposed according to the invention, which is implemented in a freewheeling manner and has a low response voltage and a residual voltage at the same time. The functional elements (such as graphite sheets), control elements and separation gaps of the individual spark gaps are designed as a single module and are separated from other loads such as pressure and soot and are therefore not compromised.

[0059] The embodiment without freewheeling is based on a series connection of the individual spark gaps with an additional control element. It is thus possible to obtain a spark arrester in which no freewheeling flow occurs, even in the presence of surge current loads, since the existing reverse voltage of the spark gap is always higher than the applied supply voltage.

[0060] A number of advantages are obtained by the freewheeling embodiment of the arrester according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com