A preparation method of electric dry distillation tobacco sheet

A technology of tobacco sheet and tobacco, which is applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problem that the thickness concentrate of the regenerated tobacco sheet cannot meet the needs of electric dry distillation type cigarettes, etc., and achieves avoiding secondhand smoke, reducing harm, and strengthening The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

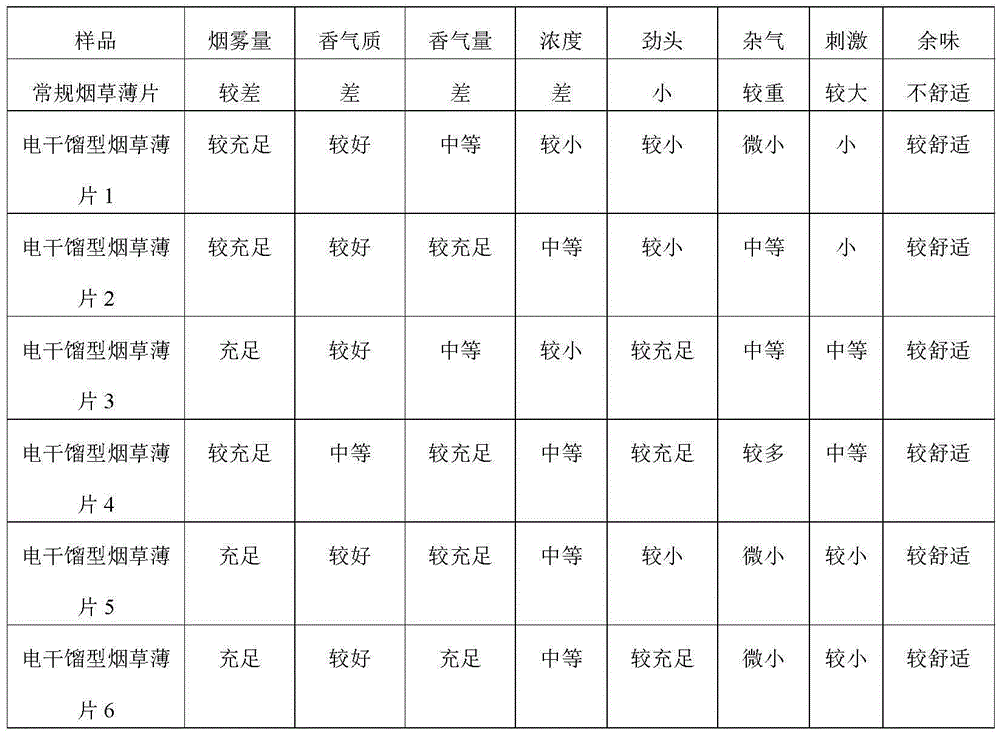

Examples

Embodiment 1

[0018] (1) Weigh 100g of flue-cured tobacco leaves, add 300g of 95% ethanol, and soak at room temperature for 1 week. Then filter out the tobacco leaves and concentrate below 50°C to obtain tobacco extract.

[0019] (2) Coat the extracted tobacco extract on the tobacco sheet base with a thickness of 0.2mm, coat 400g of the tobacco sheet base per 100g of tobacco extract, and dry at 40°C to obtain the tobacco sheet base spray The content is 200g / m 2 , a thickness of 0.35mm, and a moisture content of 11%.

[0020] (3) Percentage by weight: 65% propylene glycol, 15% glycerin, 3% deionized water, 5% alcohol, 6% natural flavor, and 6% tobacco extract are mixed to obtain an atomizer flavor. Then the atomizing agent spice is sprayed on the tobacco sheet base that has been coated with tobacco extract, and the coating amount is 100g tobacco sheet base spraying the amount of atomizer spice being 15g, i.e. the amount of 15% atomizer spice .

[0021] (4) The tobacco sheet base sprayed ...

Embodiment 2

[0023] (1) Weigh 100g of air-cured tobacco leaves, add 200g of 75% ethanol, and soak at room temperature for 1 week. Then filter out the tobacco leaves and concentrate below 50°C to obtain tobacco extract.

[0024] (2) Coat the extracted tobacco extract on the tobacco sheet base with a thickness of 0.1mm, coat 100g of the tobacco sheet base per 100g of tobacco extract, and dry at 50°C to obtain the tobacco sheet base spray The content is 250g / m 2 , a thickness of 0.3mm, and a moisture content of 10%.

[0025] (3) Percentage by weight: 75% propylene glycol, 10% glycerin, 1% deionized water, 10% alcohol, 1% artificial flavor, and 5% tobacco extract are mixed to obtain an atomizer flavor. Then the atomizing agent flavoring is sprayed on the tobacco sheet base that has been coated with tobacco extract, and the coating amount is 100g tobacco sheet base spraying the amount of atomizing agent flavoring as 50g, i.e. the amount of 50% atomizing agent flavoring .

[0026] (4) The to...

Embodiment 3

[0028] (1) Weigh 100g of Burley tobacco leaves, add 200g of 95% ethanol, and extract for 1-4 hours under the condition of heating, condensing and reflux. Then filter out the tobacco leaves and concentrate below 50°C to obtain tobacco extract.

[0029] (2) Coat the extracted tobacco extract on the tobacco sheet base with a thickness of 0.4mm, coat 1000g of the tobacco sheet base per 100g of tobacco extract, and dry at 70°C to obtain the tobacco sheet base spray The content is 150g / m 2 , a thickness of 0.4mm, and a moisture content of 12%.

[0030] (3) Percentage by weight: 20% propylene glycol, 45% glycerin, 10% deionized water, 5% alcohol, 10% natural flavor, and 10% tobacco extract are mixed to obtain an atomizer flavor. Then the atomizing agent spice is sprayed on the tobacco sheet base that has been coated with tobacco extract, and the amount of spraying atomizer spice on the 100g tobacco sheet base is 2g, i.e. the amount of 2% atomizer spice .

[0031] (4) The tobacco ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com