Methods of forming graphene

A graphene and graphene technology, applied in the field of graphene formation, can solve problems such as inability to obtain high-yield graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

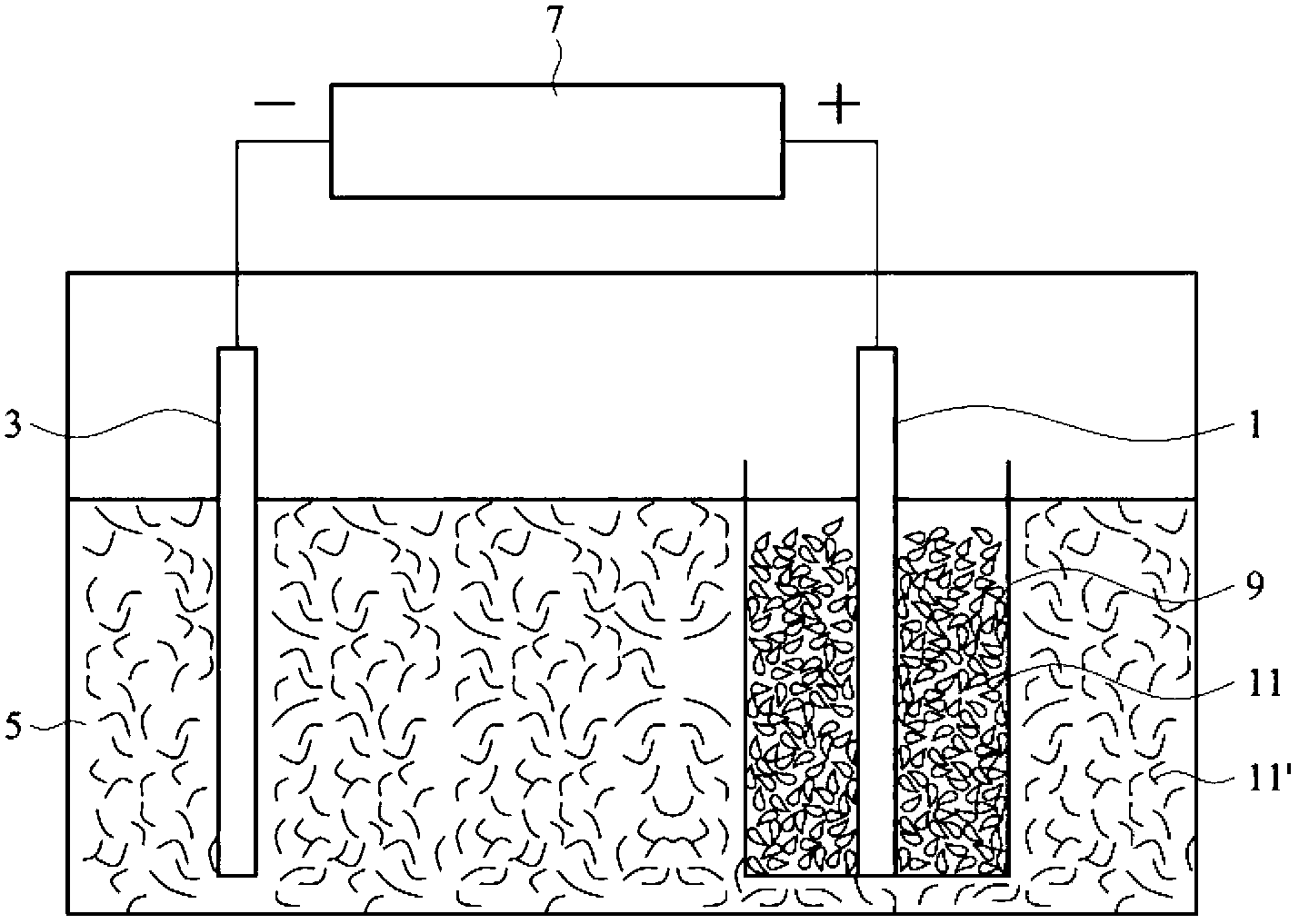

[0036] Prepare 100ml of 0.24M sulfuric acid aqueous solution as acidic electrolyte, its pH value is about 0.7. After coating a graphite plate (purchased from Central Carbon, 20×20×2mm, 1.44g) with a semipermeable membrane (single-layer polypropylene, purchased from Celgard) with a pore size of about 40 nm, the graphite plate was connected to the positive electrode of the DC power supply. After the platinum wire is connected to the negative electrode of the DC power supply, the graphite plate covered by the semi-permeable membrane and the platinum wire are immersed in the acid electrolyte. The DC power supply first conducts pre-electrolysis at a constant voltage of 2.5V for one minute, so that the graphite plate is fully soaked in the electrolyte. Then the voltage was adjusted to 10V for 3 hours of electrolysis, and it was observed that the graphite plate gradually peeled off, and a black solid diffused through the semipermeable membrane into the acidic electrolyte. Collect th...

Embodiment 2

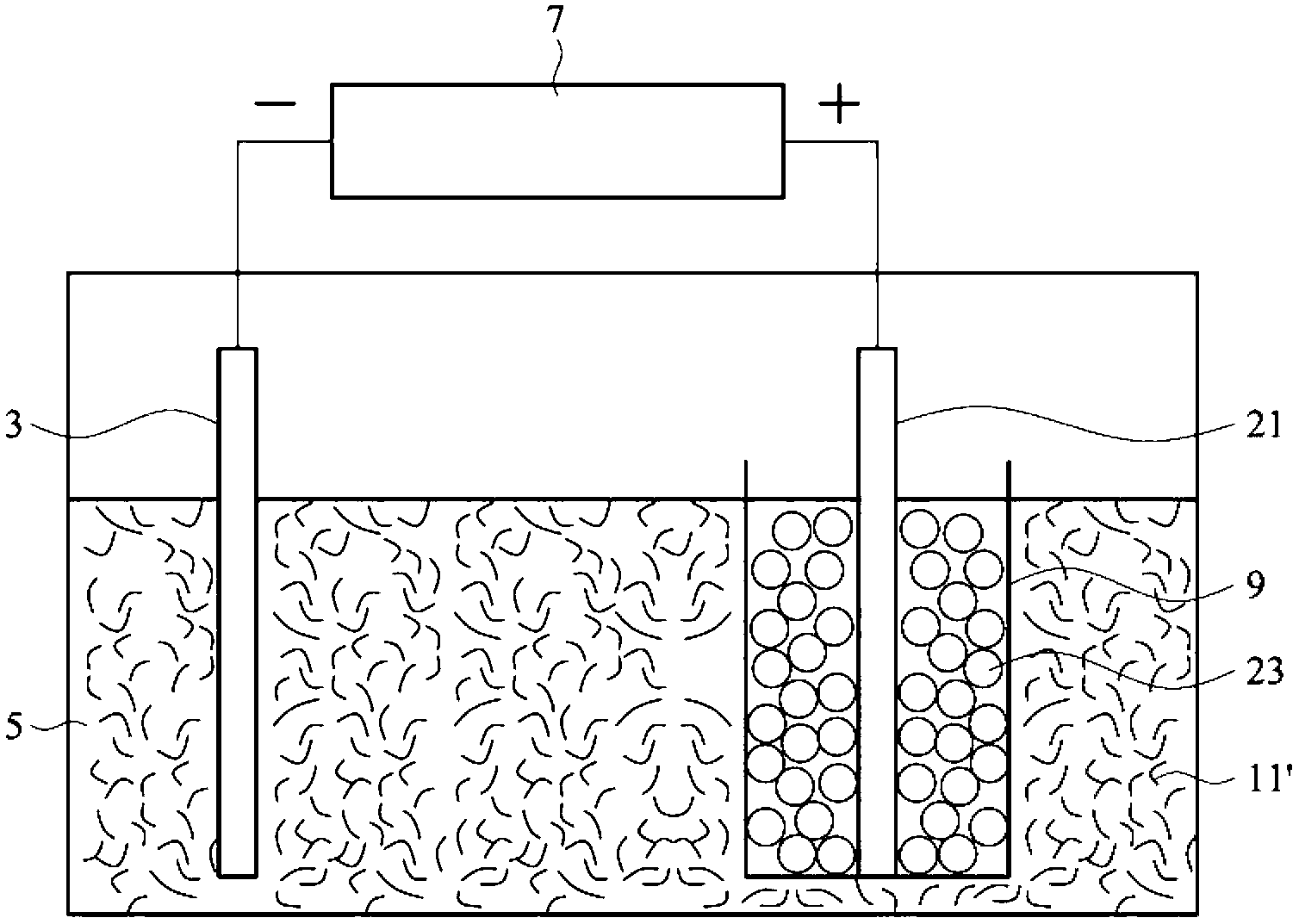

[0038] Prepare 100ml of 0.24M sulfuric acid aqueous solution as acidic electrolyte, its pH value is about 0.7. A semipermeable membrane with a pore size of about 40 nm (single-layer polypropylene, purchased from Celgard) was coated with platinum wire and graphite particles (purchased from Central Carbon, with a particle size of 3 μm, a total of 2 g), and the platinum wire coated with the semipermeable membrane Connect the positive terminal of the DC power supply. After another platinum wire is connected to the negative pole of the DC power supply, the platinum wire covered by the semi-permeable membrane and the other platinum wire are immersed in the acid electrolyte. The DC power supply first performs a one-minute pre-electrolysis at a constant voltage of 2.5V, so that the graphite particles are fully infiltrated with the electrolyte. Then, the voltage was adjusted to 10V for 3 hours of electrolysis, and it was observed that the graphite particles peeled off gradually, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap