Method for extracting schisandra volatile oil with 9, 12-octadecadienoic acid serving as principal component through low temperature evaporation

A technology of octadecadienoic acid and volatile oil of Schisandra chinensis, which is applied in the directions of essential oils/spice, fat generation, etc., can solve the problems that the effective components cannot be further effectively separated and purified, cannot be separated, and the purification cost is high, and the improvement of medical Medicinal value, optimized control of process parameters, improved energy conservation and emission reduction, and reduced purification costs

Inactive Publication Date: 2013-07-03

CHANGCHUN UNIV OF TECH

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

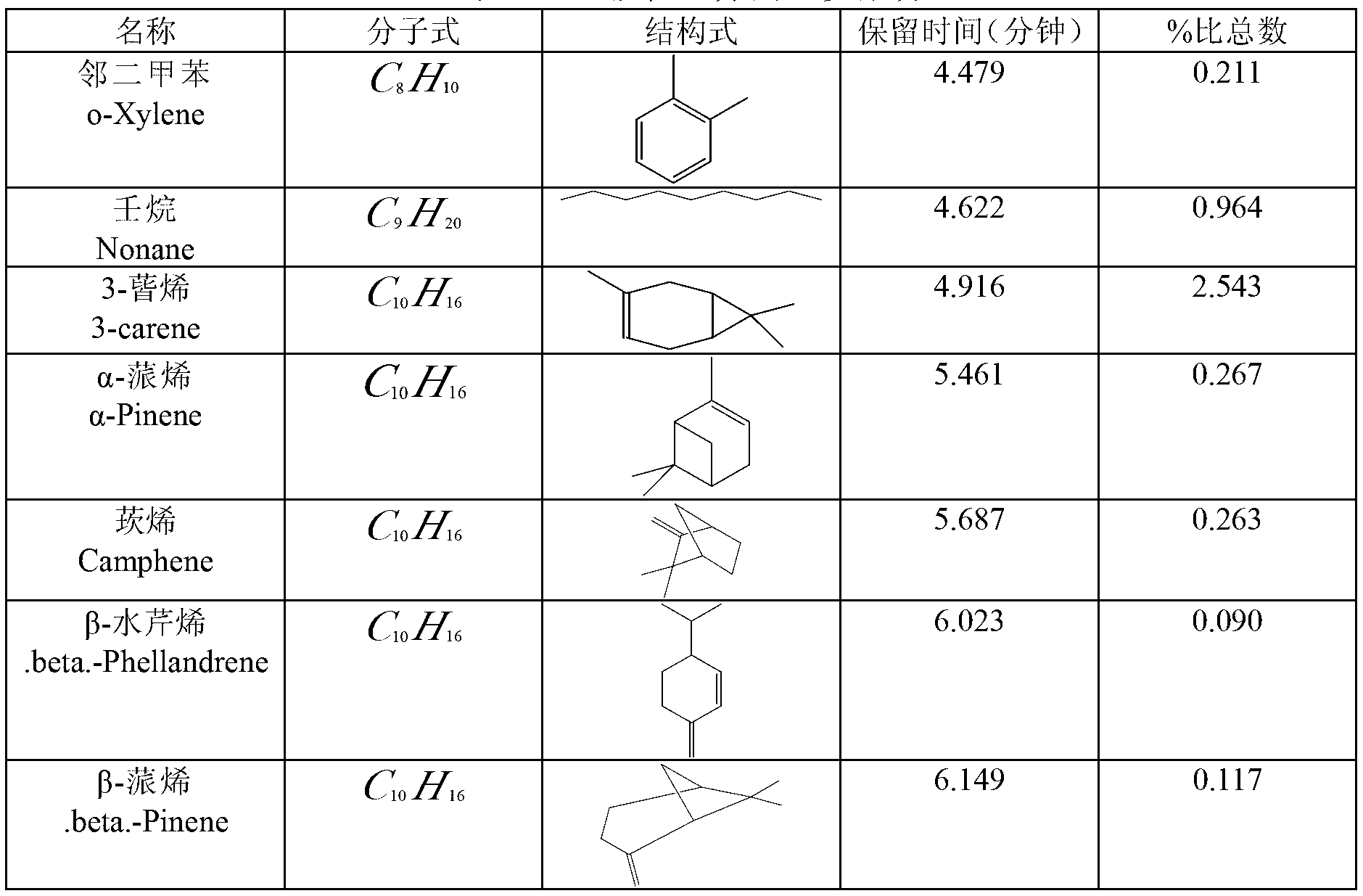

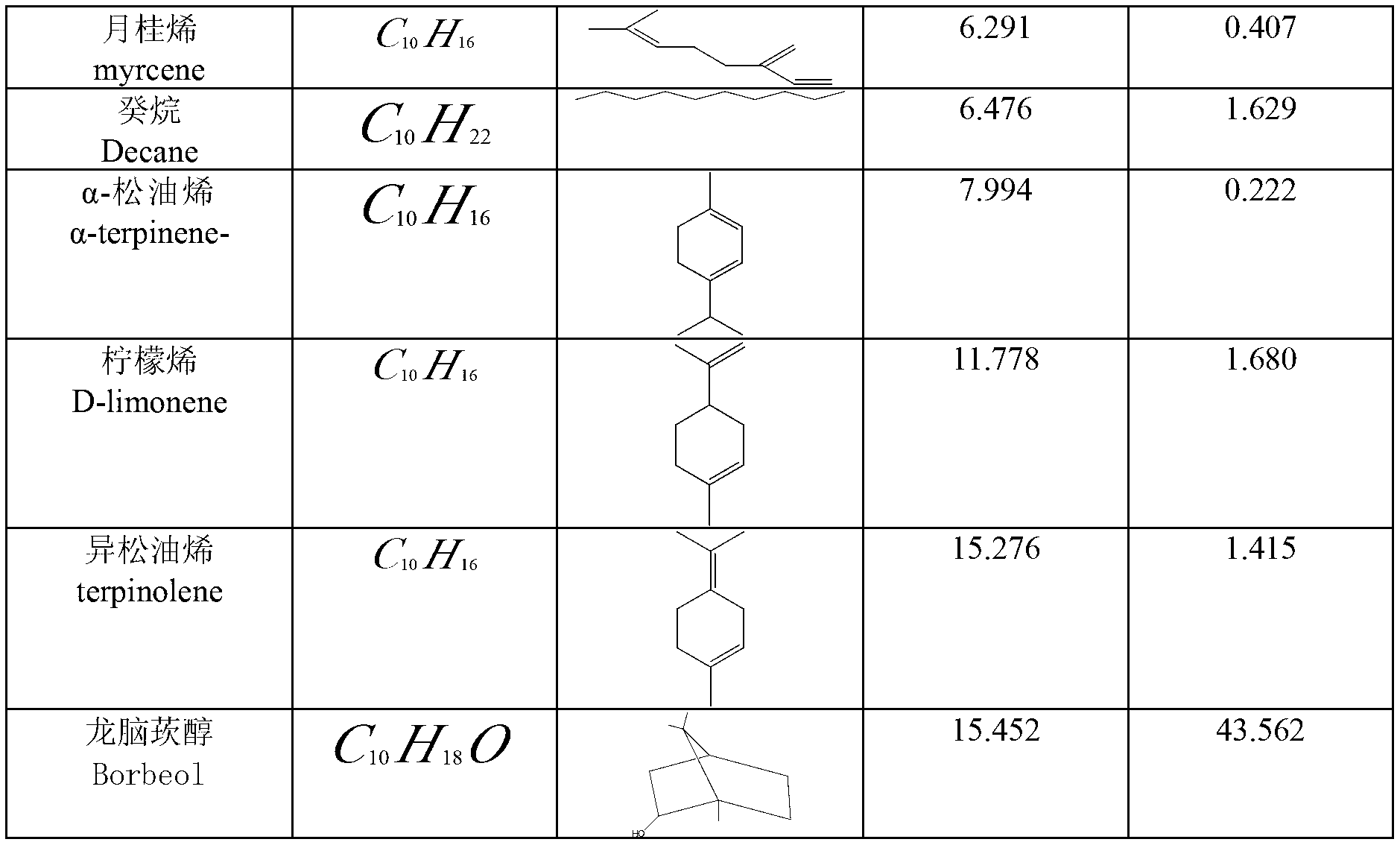

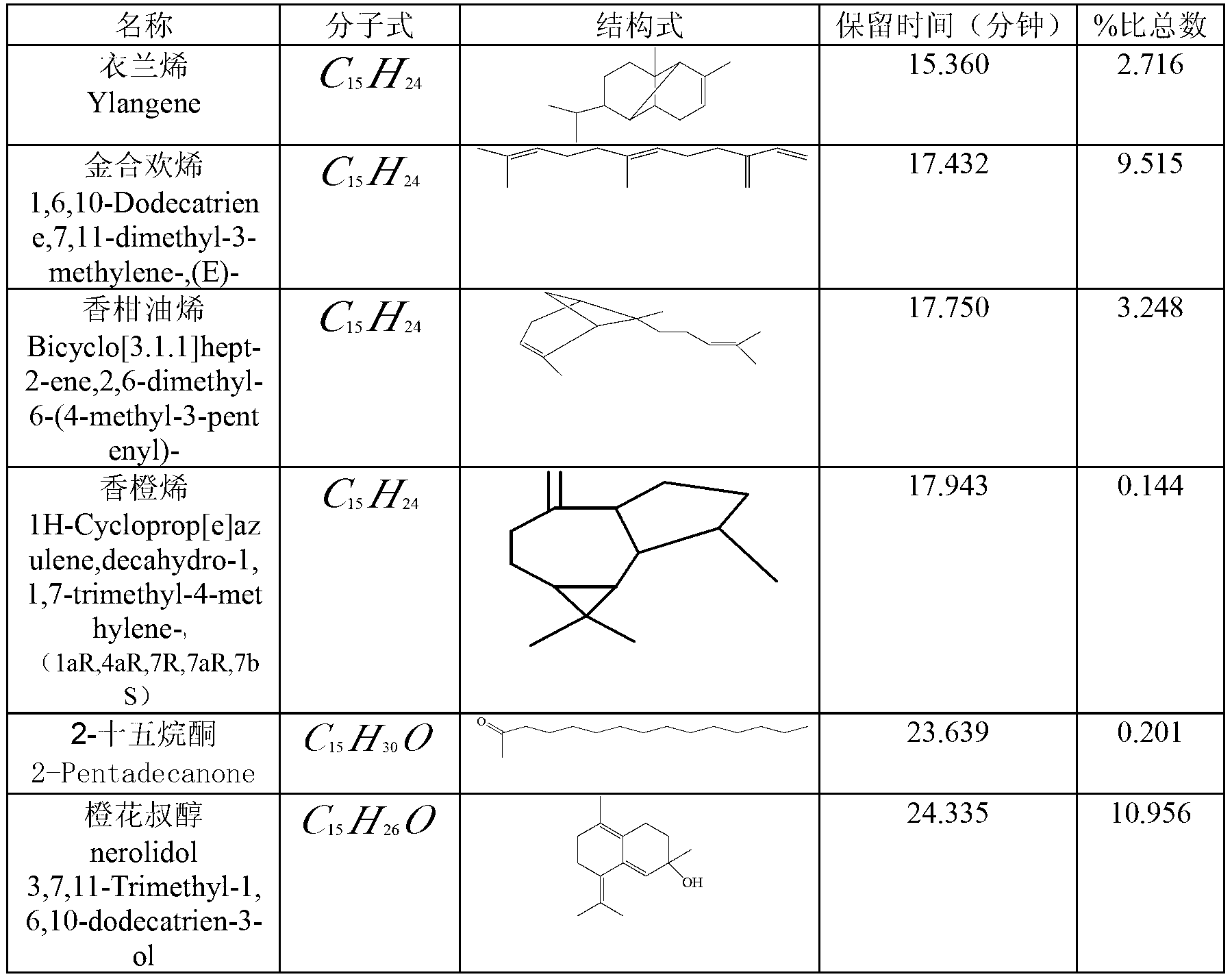

[0003] In order to solve the problem that various effective components with high content in the volatile oil of Schisandra chinensis cannot be further effectively separated and purified, and its purification cost is high and the practicability is poor (only methods such as GC-MS can be used for component detection, and effective separation cannot be achieved. Especially for technical problems such as industrialized separation and purification), the present invention provides a method for extracting active ingredients in Schisandra volatile oil by using low-temperature evaporation molecular distillation technology, which can quickly and effectively further separate and purify Schisandra volatile oil, extract The different components of Schisandra are used in different health foods and pharmaceutical products according to their functions, which increases the medical value of Schisandra chinensis

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a method for extracting schisandra volatile oil with 9, 12-octadecadienoic acid serving as a principal component through low temperature evaporation and belongs to the technical field of schisandra purification. According to the method, a molecular distillation device is used for performing first-stage, second-stage and third-stage molecular distillation on schisandra volatile oil which is obtained with a supercritical carbon dioxide extraction method sequentially. The conditions for the first-stage molecular distillation is that the distillation temperature is 80 DEG C, the pressure ranges from 500 Pa to 10000 Pa, and the rotation speed of a film wiping motor is 245 revolutions per minute; the conditions for the second-stage molecular distillation is that the distillation temperature is 150 DEG C, the pressure ranges from 10 Pa to 500 Pa, the rotation speed of the film wiping motor is 250 revolutions per minute; and the conditions for the third-stage molecular distillation is that the distillation temperature is 170 DEG C, the pressure ranges from 10 Pa to 50 Pa, and the rotation speed of the film wiping motor is 360 revolutions per minute. Finally 9, 12-octadecadienoic acid and the like are obtained, and the schisandra volatile oil is purified. The method can rapidly and effectively purify the schisandra volatile oil, the purification cost is reduced, medical and medicinal values of schisandra are increased, and the technology is energy-saving and environment-friendly.

Description

technical field [0001] The invention relates to the technical field of purification of schisandra volatile oil, in particular to a method for purifying schisandra volatile oil by using low-temperature evaporation molecular distillation technology. Background technique [0002] Schisandra chinensis has obvious sedative effect in the central nervous system, has the effect of dilating blood vessels in the cardiovascular system, increases the activity of myocardial metabolic enzymes, improves the nutrition and function of the myocardium, and its volatile components have anti-oxidation and anti-convulsant effects. At present, there are few domestic studies on the volatile oil of Schisandra chinensis. The existing method of separation and purification of volatile oil of Schisandra chinensis is atmospheric distillation, which has a low purification rate and high energy consumption. Many medicinal ingredients cannot be effectively purified, resulting in increased purification costs. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C11B9/02

Inventor 李慧尤文张德江娄利峰李颖李秀歌韩金历高冷

Owner CHANGCHUN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com