Series of eccentrically swinging reducer

A technology of eccentric swing and reducer, which is applied in the direction of mechanical equipment, transmission devices, transmission device parts, etc., can solve the problems of unrealized sharing, and achieve the effect of sharing and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

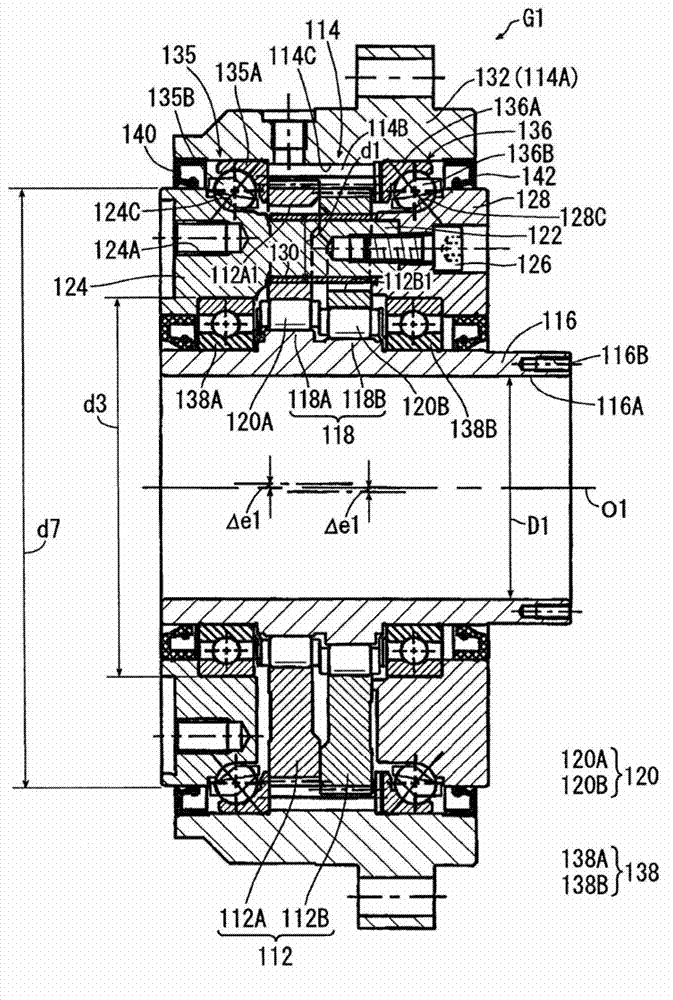

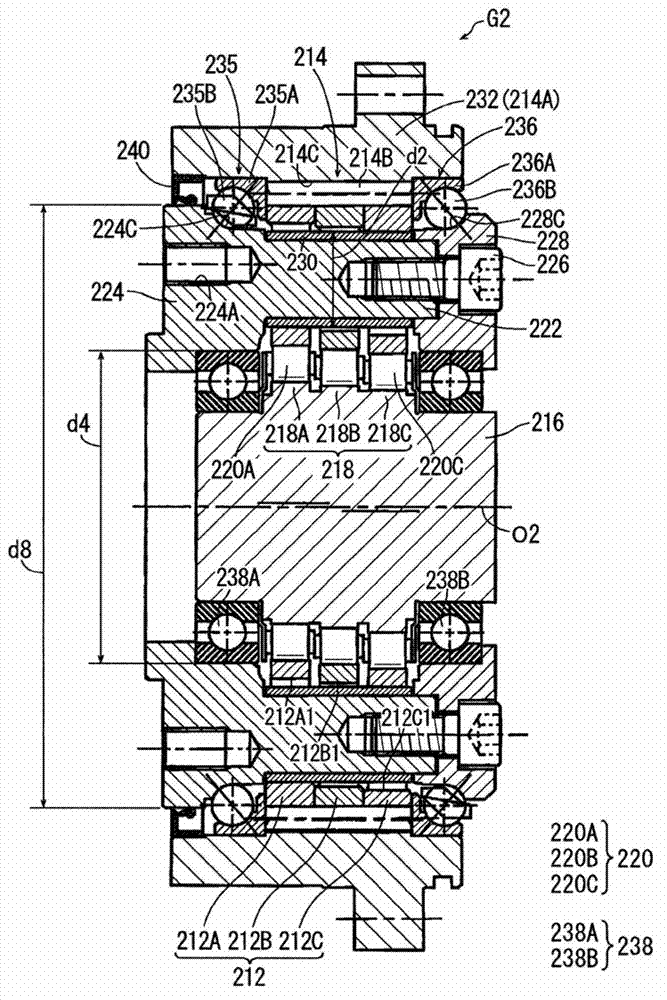

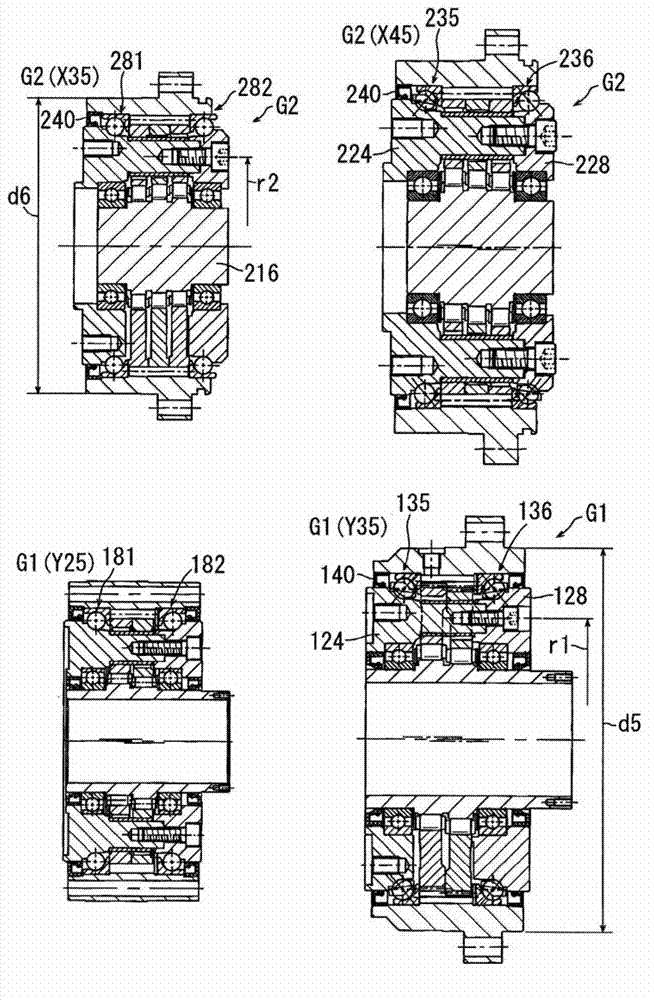

[0021] Hereinafter, a series of eccentric oscillating speed reducers according to an example of an embodiment of the present invention will be described in detail with reference to the drawings.

[0022] The reducer series consists of a first sub-series and a second sub-series, the first sub-series consists of a plurality of reducers with a hollow part with a larger hollow diameter, the second sub-series consists of a A series of hollow parts with a hollow diameter of the hollow part (specifically, the minimum diameter of the hollow part is zero, that is, there is no hollow part) consisting of a plurality of reduction gear units.

[0023] figure 1 It is a cross-sectional view showing an example of a reduction gear having a hollow portion with a large hollow diameter belonging to the first sub-series (hereinafter, appropriately referred to as the first reduction gear G1), figure 2 It is a cross-sectional view showing an example of a reduction gear without a hollow part (hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com