Fluid connector devices and methods of making and using the same

A technology of connectors and connector components, applied in chemical instruments and methods, supporting appliances, laboratory appliances, etc., can solve problems such as increasing pressure and restricting the applicability of microfluidic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

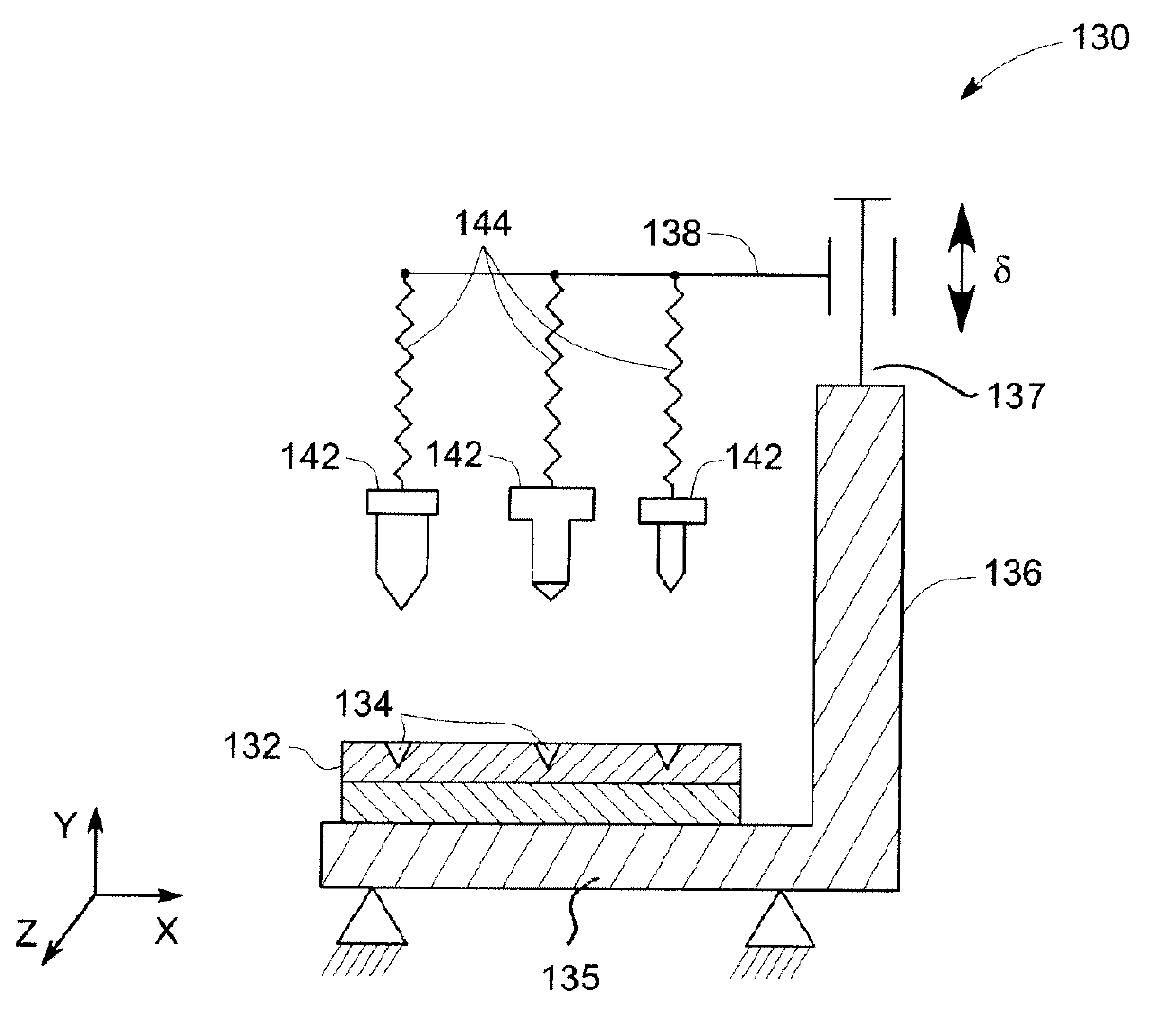

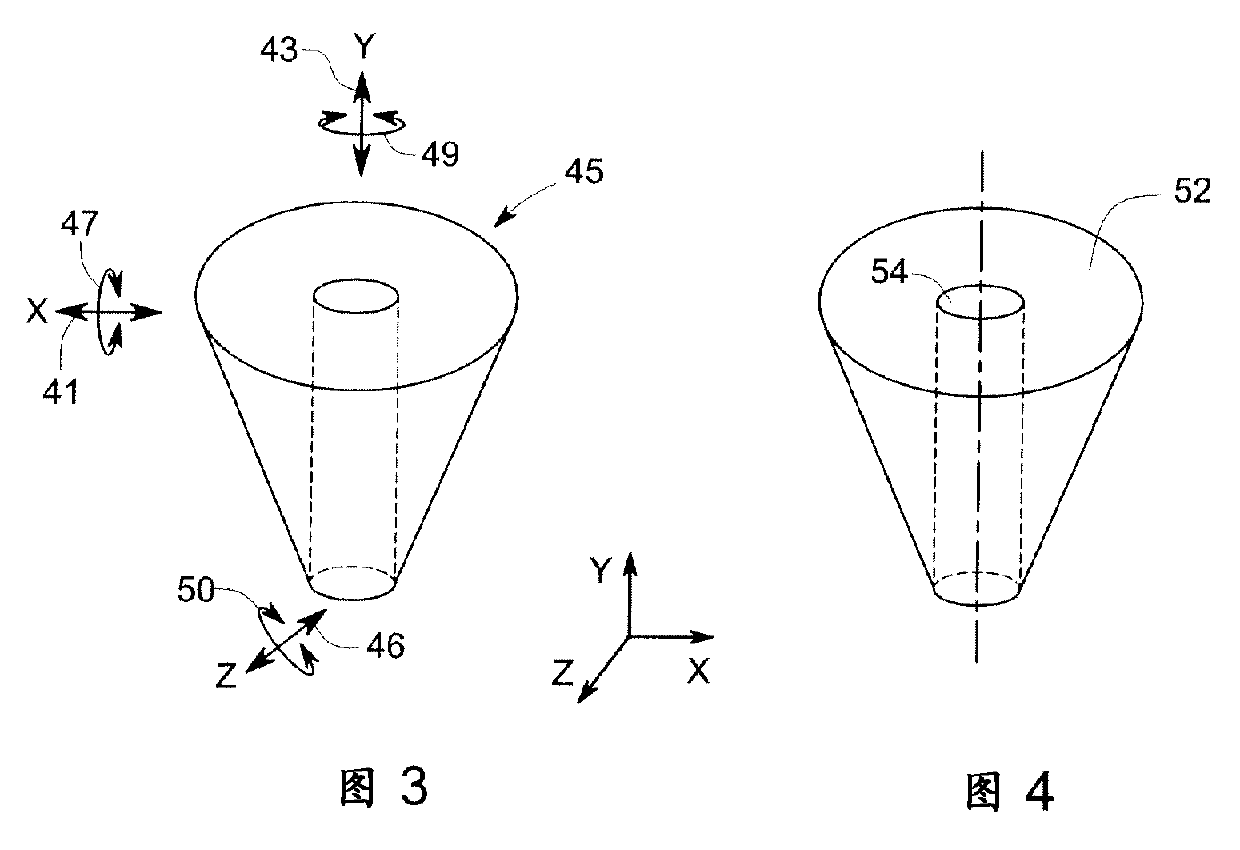

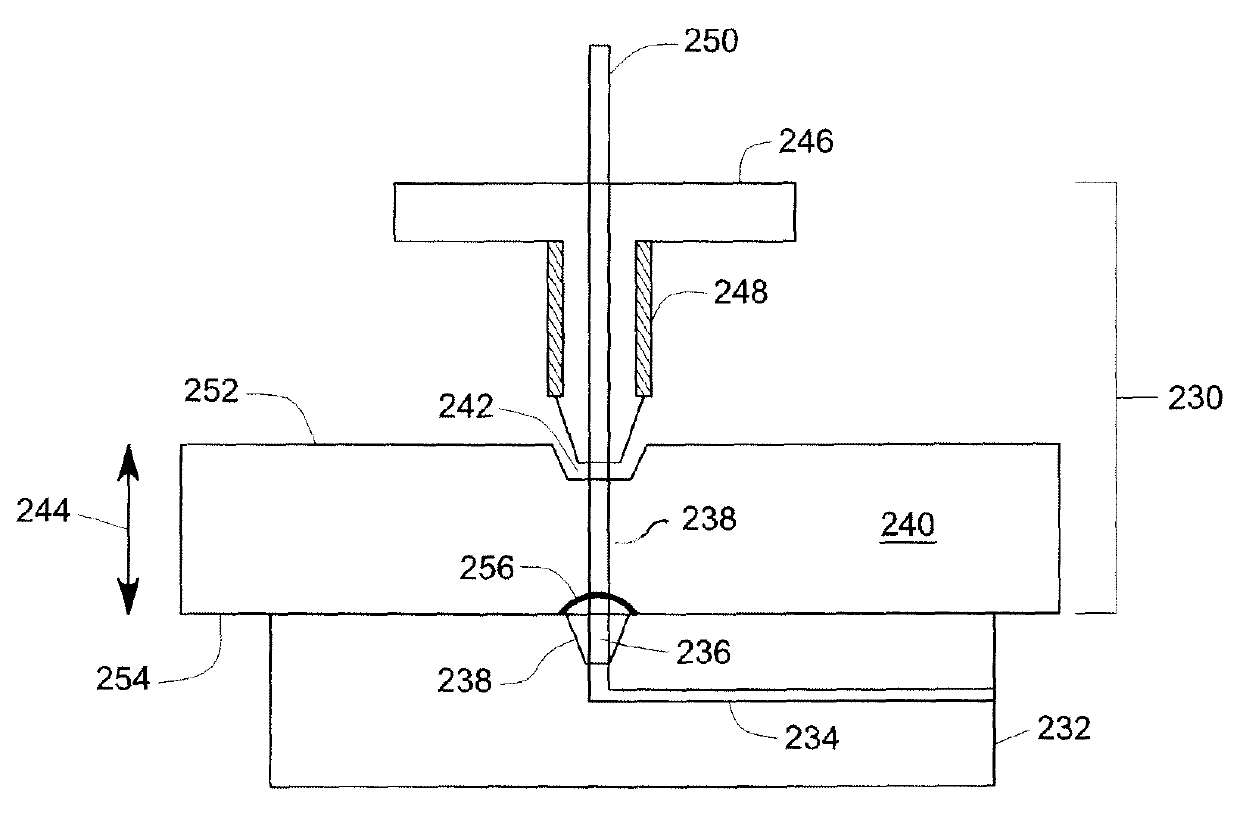

[0023] The present invention relates to microfluidic interconnect devices for introducing or extracting fluids (liquid or gas) into or from microfabricated fluidic devices, such as microfluidic devices. In certain embodiments, the fluidic connector device functions as a microfluidic interconnection device to introduce or extract fluids from the microfluidic device. Fluidic connector devices can be used to interface microfluidic devices with each other or with other fluidic components and systems such as, but not limited to, pumps, filters, syringes, aerosol collectors, flow cytometers, and chemical analyzers. In one embodiment, a fluidic connector arrangement can couple at least one fluidic conduit to a corresponding port of the microfluidic device.

[0024] In certain embodiments, the fluidic connector devices can be used for synthetic or analytical operations. As described in detail below, the present technology offers several advantages for use in chemical analysis or synt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com