Automobile brake shoe wing plate bending die

An automobile braking and wing plate technology, applied in the field of stamping die, can solve the problem that the brake shoe wing plate is prone to bending and rebound, affecting the braking effect of the brake shoe wing plate, etc., so as to eliminate the rebound and prevent the material from running. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

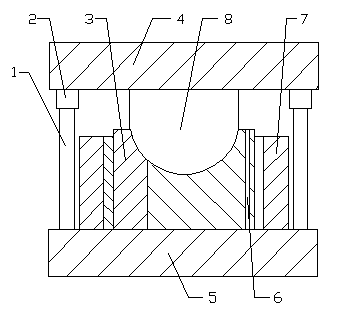

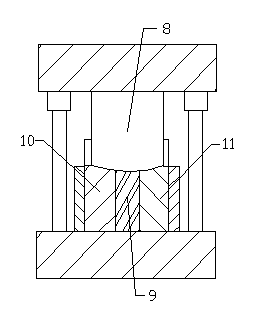

[0009] The automobile brake shoe wing plate bending mold as shown in the figure includes an upper mold and a lower mold. The material block 9, the left part 10 of the die and the right part 11 of the die are composed of the upper die mainly consisting of the guide sleeve 1, the upper template 4 and the punch 8, the left part 10 of the die, the right part 11 of the die and the The die ejector block 9 is combined into a shape with a cross-section of "︺", the ejector block is installed in the middle of the left part 10 of the die and the right part 11 of the die, the left part 10 of the die, and the right part 11 of the die And the die ejector block 9 is fixed on the lower formwork 5 by the fixing plate 7, the guide post 2 is installed on the lower formwork, the positioning block 3 and the positioning pin 6 are fixedly installed on the lower formwork 5; the upper formwork 4 is provided with a guide sleeve 1, The position of the guide sleeve 1 corresponds to the position of the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com