Wear sensing device for graphene carbon motor carbon brush component and use method of wear sensing device

A graphene carbon and sensing device technology, applied in the direction of brush manufacturing and the like, can solve problems such as waste and wasted labor, and achieve the effects of accurate judgment results, reduced difficulty and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

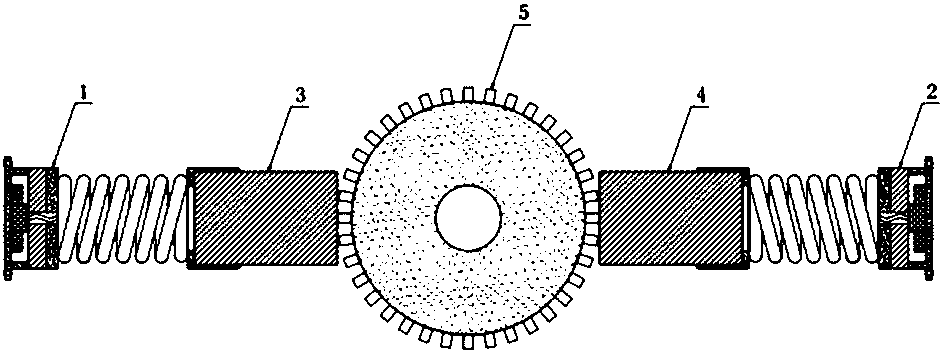

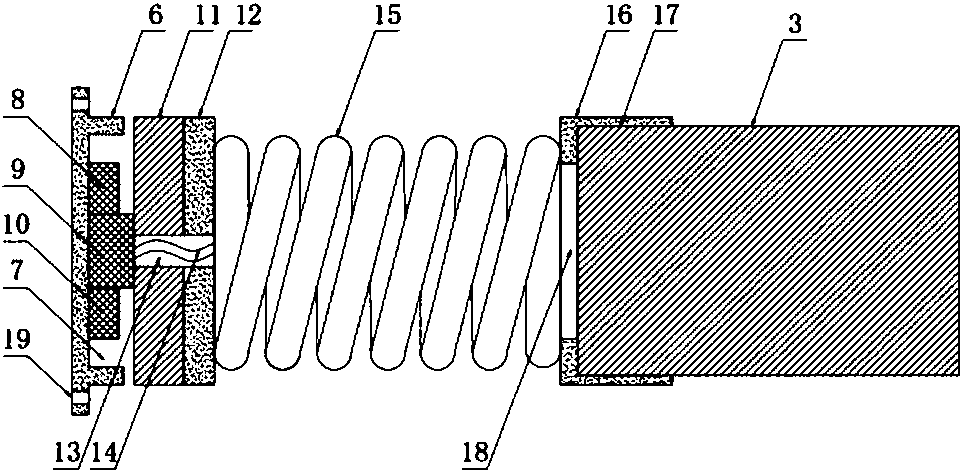

[0031] The present invention provides such as Figure 1-3 The wear sensing device of a kind of graphene carbon motor carbon brush assembly shown, comprises first sensing mechanism 1 and second sensing mechanism 2, and described second sensing mechanism 2 is located at first sensing mechanism 1- Side, the first sensing mechanism 1 is provided with a first carbon brush 3, the second sensing mechanism 2 is provided with a second carbon brush 4, the first sensing mechanism 1 and the second sensing mechanism 2 each includes a first mounting seat 6, the side of the first mounting seat 6 is provided with an accommodation groove 7, and the interior of the accommodation groove 7 is fixed with a control mechanism 8, a pressure detection mechanism 9 and an alarm mechanism 10, and the pressure detection mechanism 9. A cover plate 11 is fixed on the side, and an elastic plate 12 is provided on the side of the cover plate 11. A cable hole 13 is formed on the cover plate 11 and the elastic p...

Embodiment 2

[0034] Further, in the above-mentioned embodiment 1, a commutator 5 is provided between the first carbon brush 3 and the second carbon brush 4, and the ends of the first carbon brush 3 and the second carbon brush 4 are both Adhere to the edge of the commutator 5 so that the first carbon brush 3 and the second carbon brush 4 can work normally.

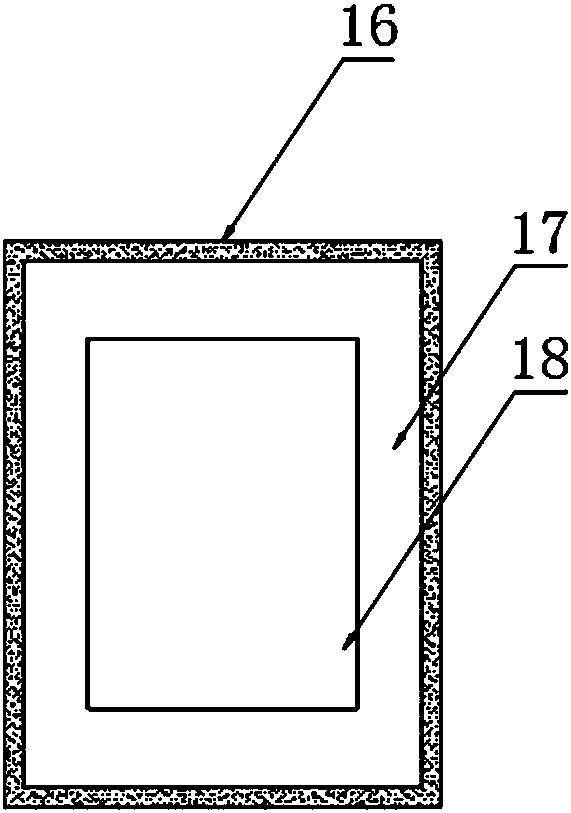

[0035] The first carbon brush 3 is arranged inside the installation groove 17 of the first sensing mechanism 1, the second carbon brush 4 is arranged inside the installation groove 17 of the second sensing mechanism 2, and the first carbon brush 3 and the second carbon brush 4 are matched with the installation groove 17, so that the first carbon brush 3 and the second carbon brush 4 are put into the installation groove 17.

[0036] The opening of the mounting groove 17 is provided with a smooth surface, the elastic plate 12 is made of rubber material, the spring 15 and the second mounting seat 16 are all made of aluminum, so that the wi...

Embodiment 3

[0042] The present invention also provides a method for using a wear sensing device of a graphene carbon motor carbon brush assembly, specifically comprising the following steps:

[0043] Step 1: Install the first sensing mechanism 1 and the second sensing mechanism 2 on the outside of the first carbon brush 3 and the second carbon brush 4 inside the motor through the threaded hole 19, and then install the first carbon brush 3 and the second carbon brush The brushes 4 are put into the cable holes 13 on the first sensing mechanism 1 and the second sensing mechanism 2 respectively, and the spring 15 is in a compressed state at this time;

[0044] Step 2: When the commutator 5 inside the motor is rotating, both the first carbon brush 3 and the second carbon brush 4 rub against the commutator 5 and conduct the current on the commutator 5;

[0045] Step 3: When the first carbon brush 3 and the second carbon brush 4 are in contact with the commutator 5 and conduct electricity, since...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com