Doorframe connecting piece

A technology for connectors and door frames, applied in the direction of corner joints/side joints, etc., can solve problems such as loopholes, material melting, and inconvenient installation, and achieve the effects of broad market prospects, long service life, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

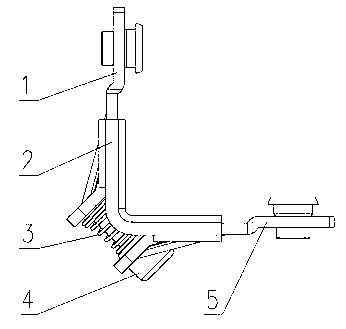

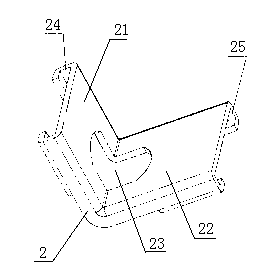

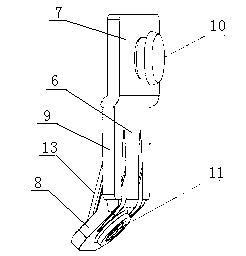

[0015] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment is a door frame connecting piece, including a main connecting piece 1, a corner 2 and a secondary connecting piece 5, and its feature is that both the main connecting piece 1 and the secondary connecting piece 5 include an upper platform connected to the middle connecting plate 6 7 and the lower inclined plate 8, side arms 9 are respectively provided on both sides of the middle connecting plate 6, T-shaped bosses 10 are arranged on the upper platform 7; the lower inclined plate 8 of the main connector 1 is provided Threaded hole 11, round hole 12 is provided on the lower slant plate 8 of the secondary connector 5; locking bolt 4 and spring 3 are arranged between the main connector 1 and the lower slant plate 8 of the secondary connector 5; The corner 2 includes an upper plate 21 and a lower plate 22 , and upper chute 24 and lower chute 25 are respectively provided on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com