Method of computing threaded connection strength based on beam-spring model

A threaded connection and strength calculation technology, applied in calculation, special data processing applications, instruments, etc., can solve problems such as no theoretical model, and achieve high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

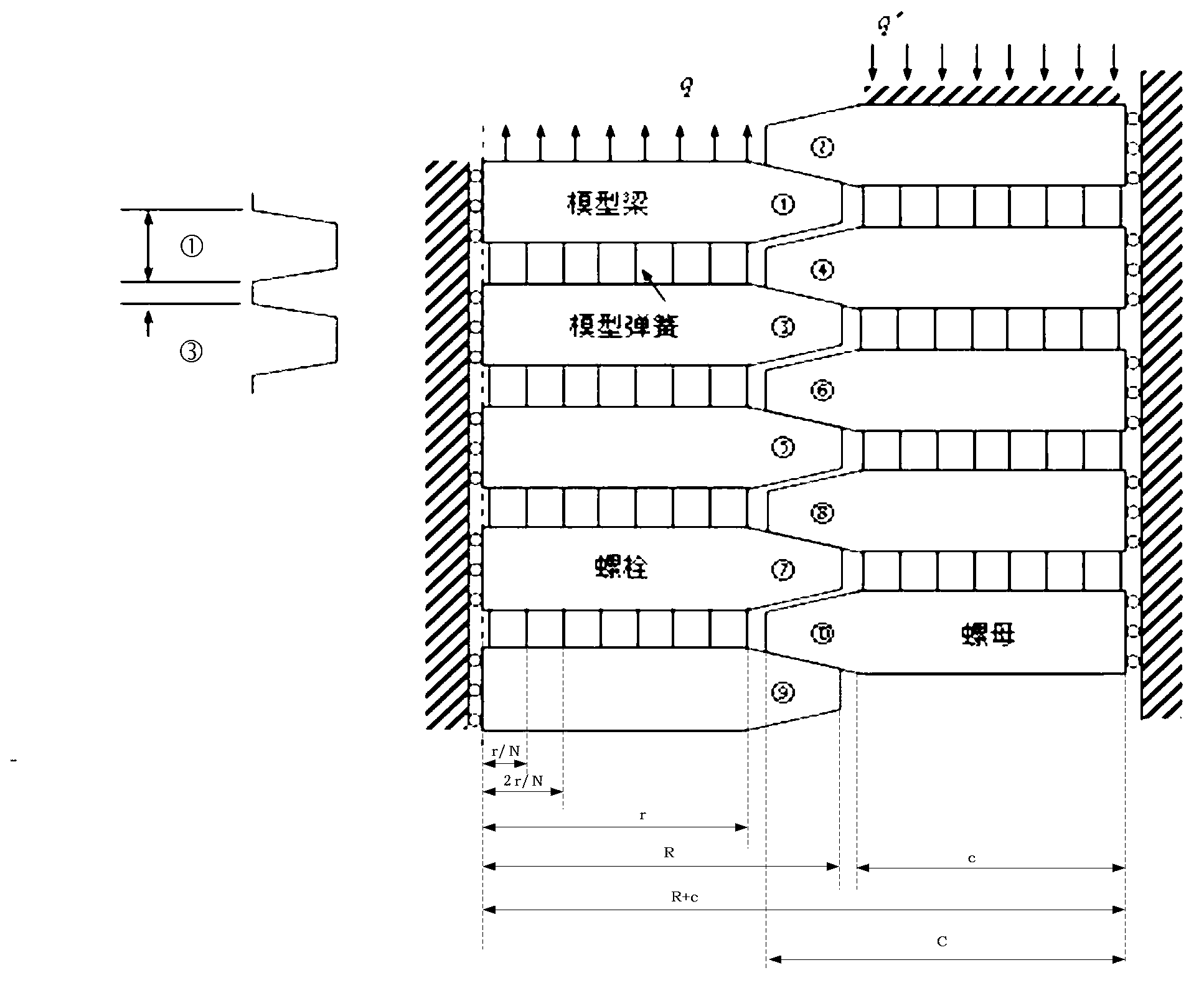

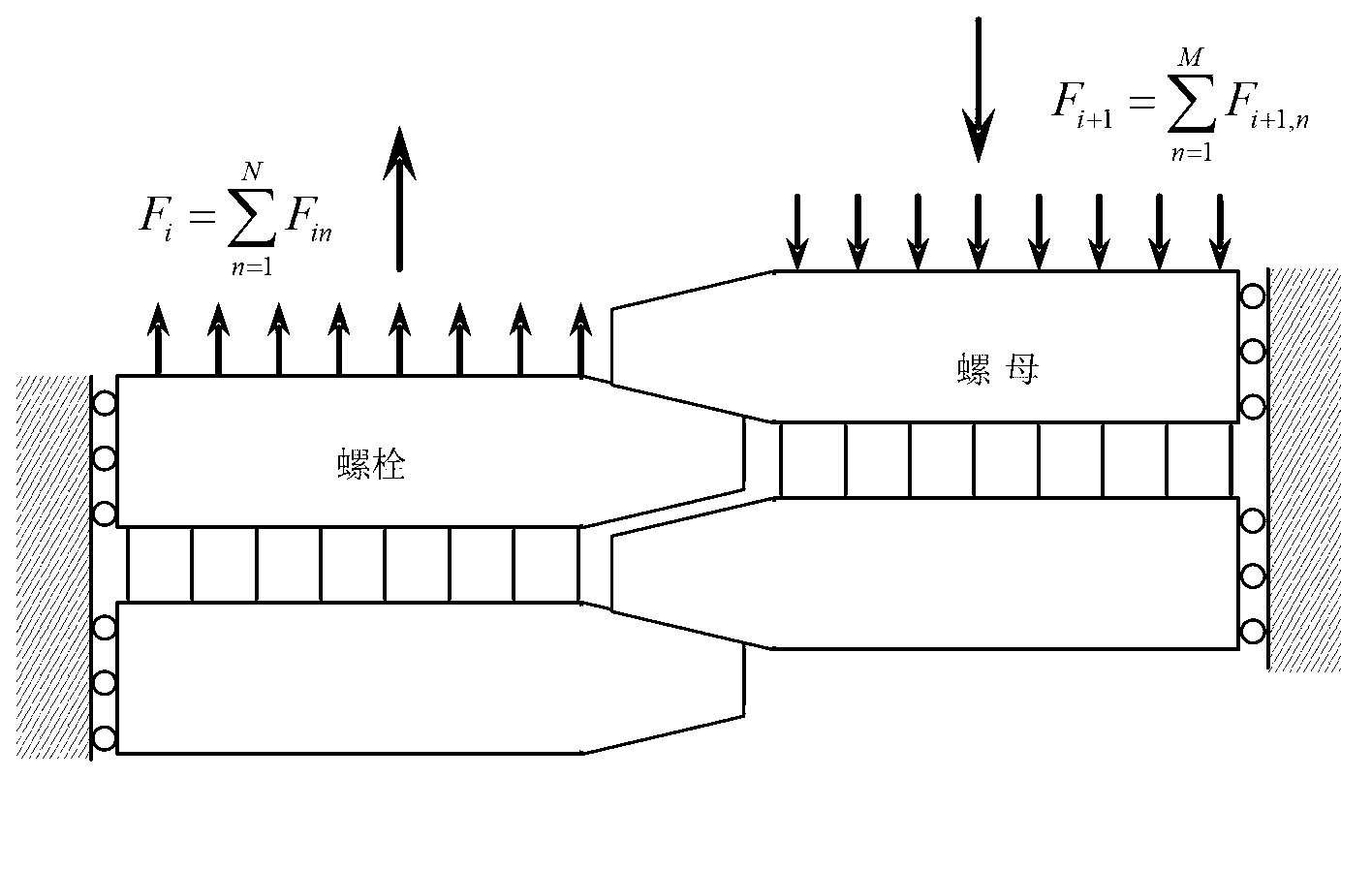

[0134] Take the elastic modulus of the material as E=2.1×10 5 N / m 2 (Ordinary carbon steel), the major and minor diameters of bolts are R=5.000mm, r=4.026mm respectively, the major and minor diameters of nuts are C=3.97mm, c=3mm respectively, the thickness of the thread teeth h=1.125, the connecting part between the teeth Thickness l=0.375, tooth half-angle π / 6 (standard M10 threaded connection), the bearing ratio of each tooth is calculated by MATLAB. The calculation results are as follows:

[0135] Table 1 Comparison of Calculation Results

[0136]

[0137] By changing the elastic modulus of the threaded connection material, the size parameters of the tooth shape, and the half-angle of the tooth shape, the force distribution of the threaded connection is optimized.

[0138] First, change the elastic modulus of the material, and the distribution is shown in Table 2 (E1 is the elastic modulus of the bolt, and E2 is the elastic modulus of the nut):

[0139] According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com