A Calculation Method of Thread Connection Strength Based on Beam-Spring Model

A technology of screw connection and spring model, applied in calculation, special data processing application, instrument, etc., can solve the problem of no theoretical model, etc., and achieve the effect of high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

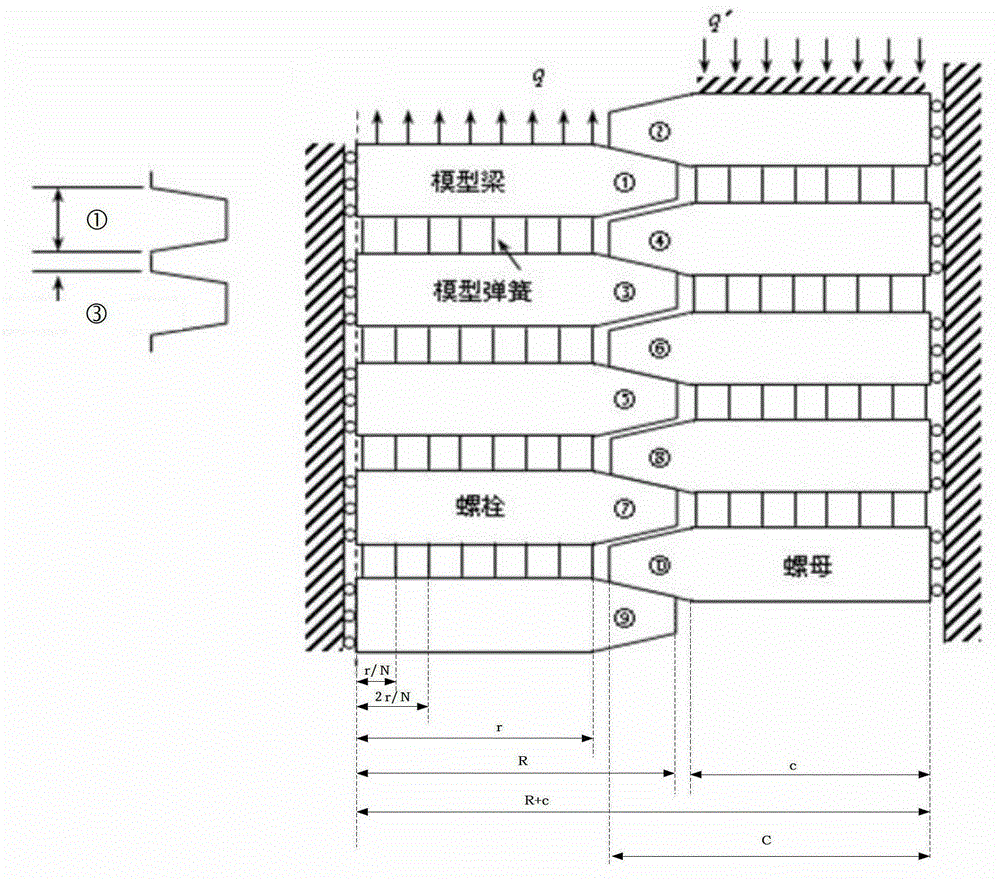

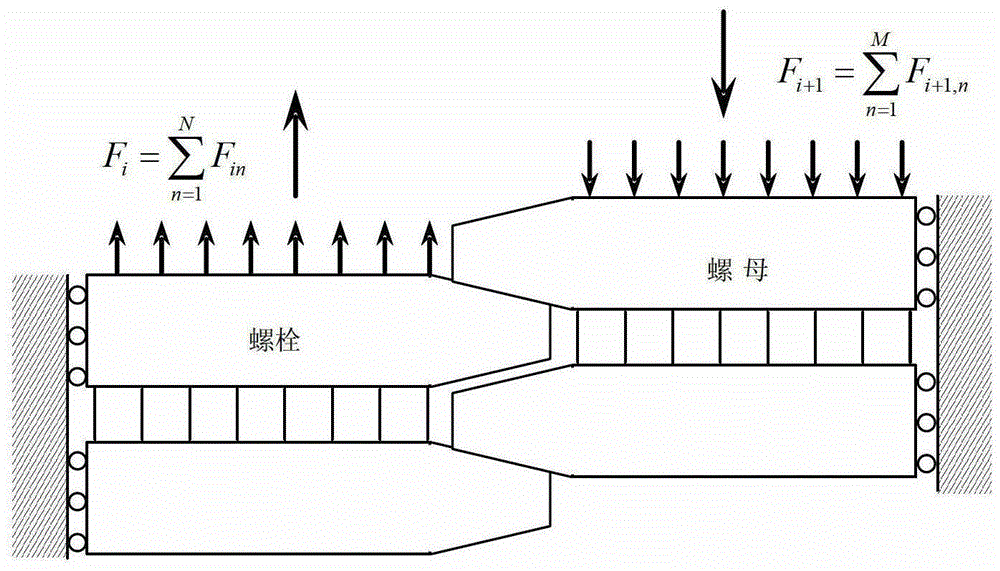

[0134] Take the elastic modulus of the material as E=2.1×10 5 N / m 2 (Ordinary carbon steel), the major and minor diameters of the bolt are R=5.000mm, r=4.026mm, the major and minor diameters of the nut are C=3.97mm, c=3mm, the thickness of the thread teeth h=1.125, the connection part between the teeth Thickness l=0.375, tooth shape half-angle π / 6 (standard M10 threaded connection), the load-bearing ratio of each tooth is calculated by MATLAB. The calculation results are as follows:

[0135] Table 1 Comparison of calculation results

[0136]

[0137] By changing the material elastic modulus of the threaded connection, the tooth profile size parameter, and the tooth profile half-angle, the force distribution of the threaded connection is optimized.

[0138] First, change the elastic modulus of the material to obtain the distribution as shown in Table 2 (E1 is the elastic modulus of the bolt, E2 is the elastic modulus of the nut):

[0139] According to Table 2, by changing the nut mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com