Fireproof and explosion-proof varistor

A varistor, explosion-proof technology, used in varistors, overvoltage protection resistors, other resistor networks, etc., can solve problems such as debris splashing, open flame casing, bursting, etc., to avoid open flames, improve safety performance, The effect of solving historic puzzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

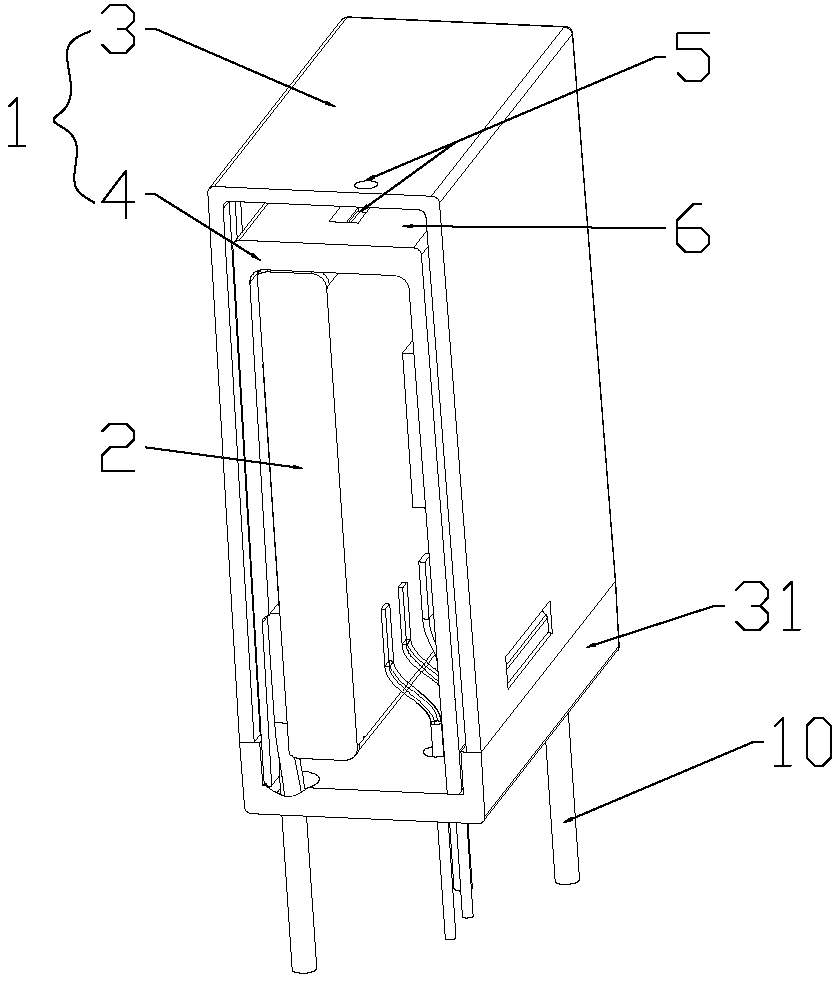

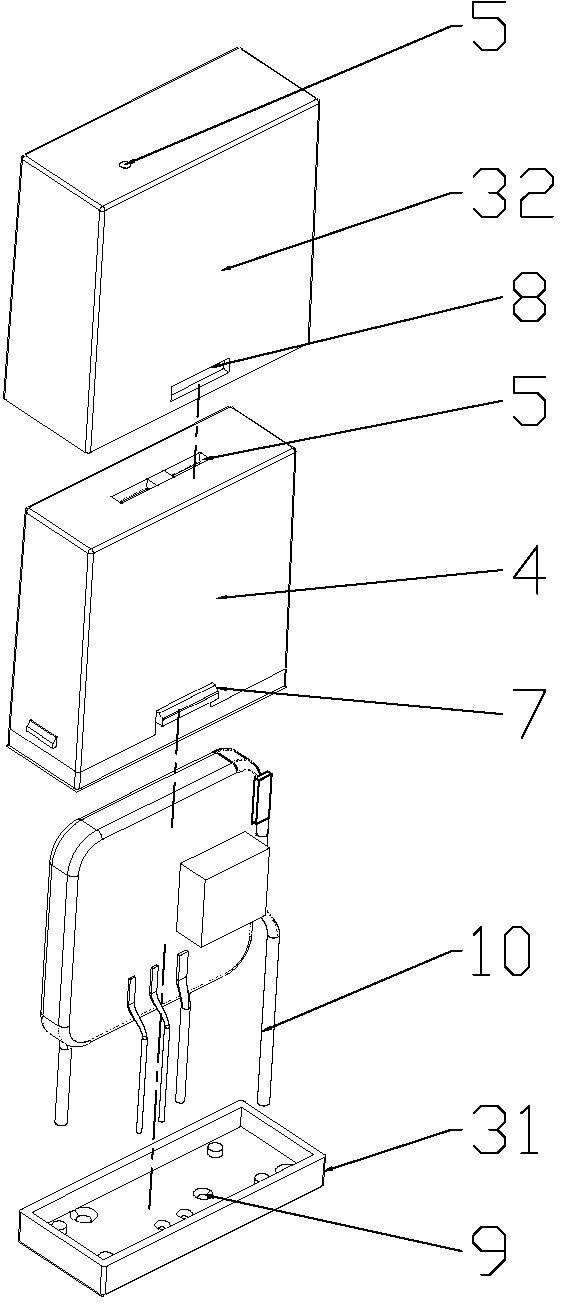

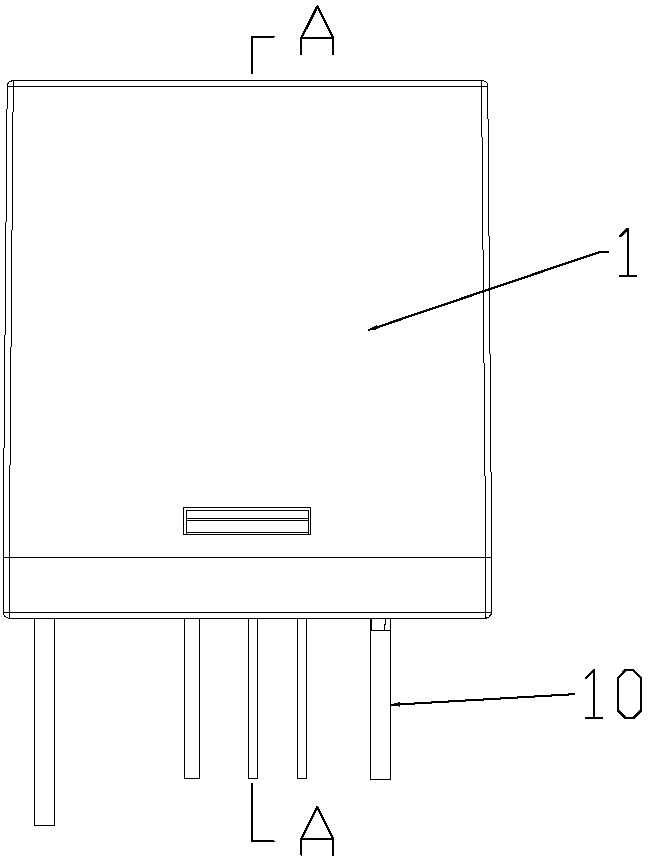

[0025] A fire-proof and explosion-proof varistor, as attached figure 1 , 2 , 3 and 4, comprising a flame retardant shell 1 and a piezoresistive device 2 fixed in the flame retardant shell, the flame retardant shell includes a cylindrical outer shell 3 and an inner shell 4, and the bottom of the inner shell is open It also has an inner cavity for containing the piezoresistive device 2. The outer shell 3 is a cavity structure and is covered outside the inner shell 4 to form a full enclosure for the inner shell; the tops of the outer shell and the inner shell are provided with exhaust hole 5, a gap is reserved between the top of the outer casing and the top of the inner casing to form a gas buffer chamber 6.

[0026] In this embodiment, the air vent at the top of the inner shell is rectangular, and the air vent at the top of the outer shell is circular. The air vent can also be square, oval or other reasonable shapes. Preferably, the area of the air vent at the top of the inn...

Embodiment 2

[0035] The difference between this embodiment and the first embodiment lies in that: the inner side of the bottom of the casing is provided with a protruding step surface or a limit block to limit the vertical displacement of the piezoresistive device 2 . Preferably, the piezoresistor device 2 is suspended in the air on the protruding step surface or the limit block, so that there is a gap between it and the bottom of the casing, which can reduce the impact on the flame-retardant case when the piezoresistor device explodes. impact.

[0036] Positioning posts for fixing the piezoresistive device 2 are provided inside the bottom of the housing 3 to limit the displacement of the piezoresistive device 2 in the horizontal direction.

Embodiment 3

[0038] The difference between this embodiment and Embodiment 1 is that the top surface of the piezoresistive device 2 is against the top inner side of the inner shell 4 and the bottom surface is against the bottom inner side of the outer shell 3, and the inner and outer shell walls are applied together. The pressure in the vertical direction realizes the limit; or, the piezoresistive device 2 and the inner shell 4 or the outer shell 3 are fixed by glue.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap