Single-layer multi-point capacitive touch screen

A capacitive touch screen, single-layer multi-point technology, applied in electrical digital data processing, instruments, data processing input/output process and other directions, can solve the problems of high ITO square resistance, inability to carry out medium and large size structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

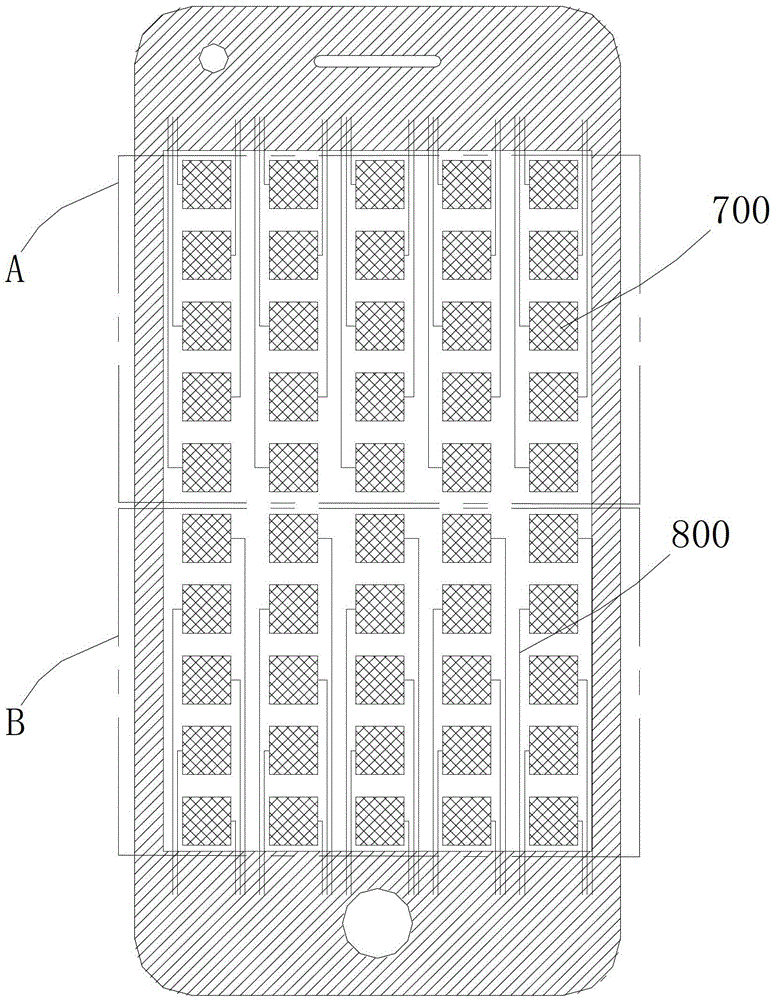

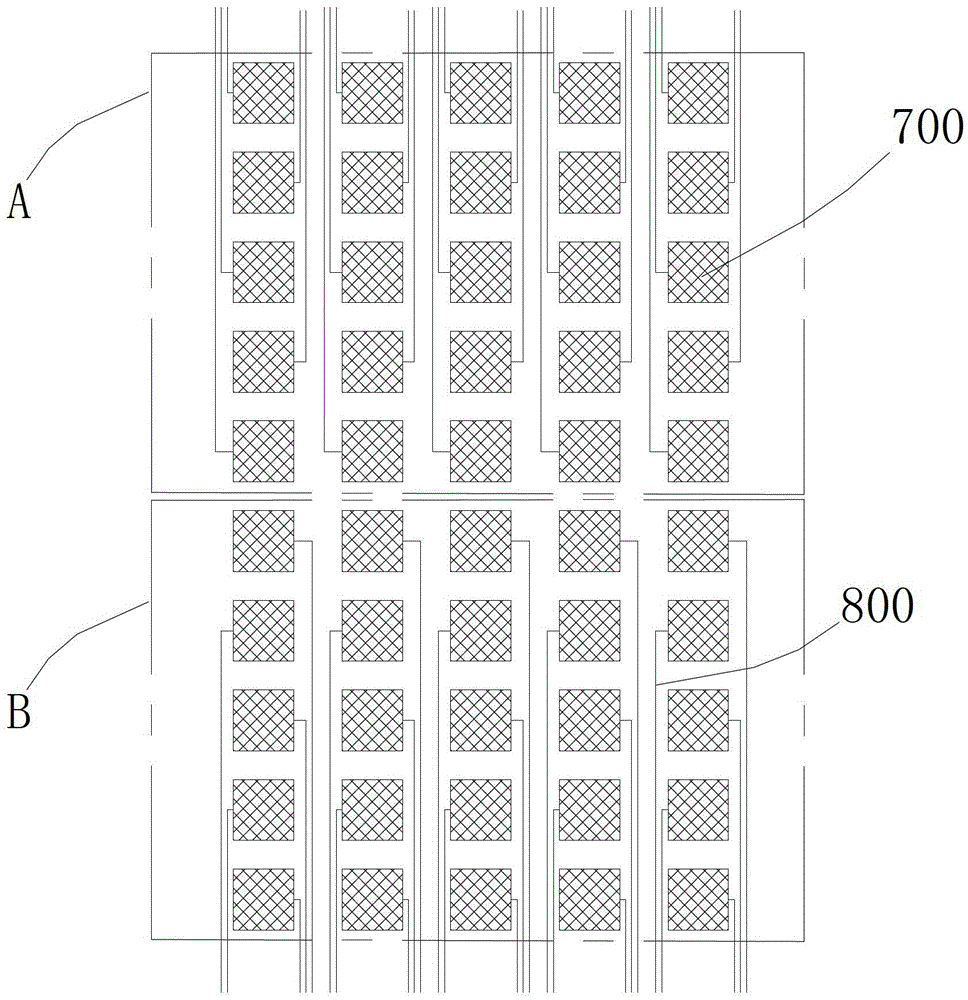

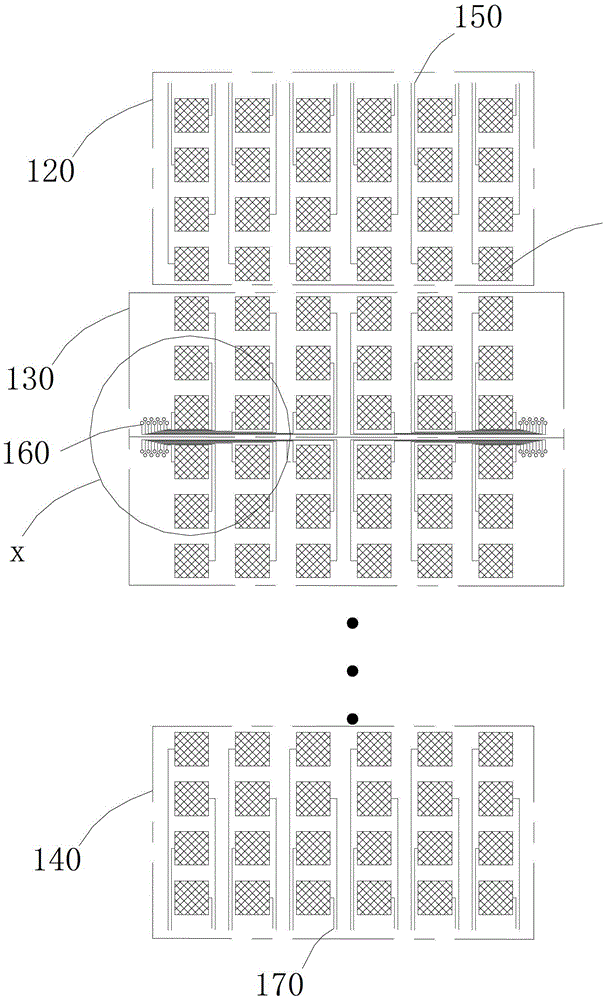

[0027] Please refer to image 3 and Figure 4 , shows a schematic diagram of a wiring structure of a single-layer multi-point capacitive touch screen of an embodiment. The single-layer multi-point capacitive touch screen is provided with a visible area, outside the visible area is the non-visible area of the touch screen, that is, the frame of the touch screen, and the non-visible area can generally be divided into the first end non-visible area (usually That is, the top non-visible area), the second end non-visible area (ie, the bottom non-visible area) and the side non-visible area are well known to those skilled in the art and will not be repeated here. Such as image 3 As shown, the visible area of the single-layer multi-point capacitive touch screen is formed by a plurality of independent electrode units 110 arrayed in multiple rows and columns, wherein each of the plurality of electrode units 110 has wires drawn out.

[0028] Such as image 3 As shown, the visibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com