Waste paper recycling device

A processing device and waste paper technology, applied in papermaking, paper machine, paper recycling, etc., can solve the problems of tearing, non-linear shape, paper jam, etc., and achieve the effect of uniform tearing strength and preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

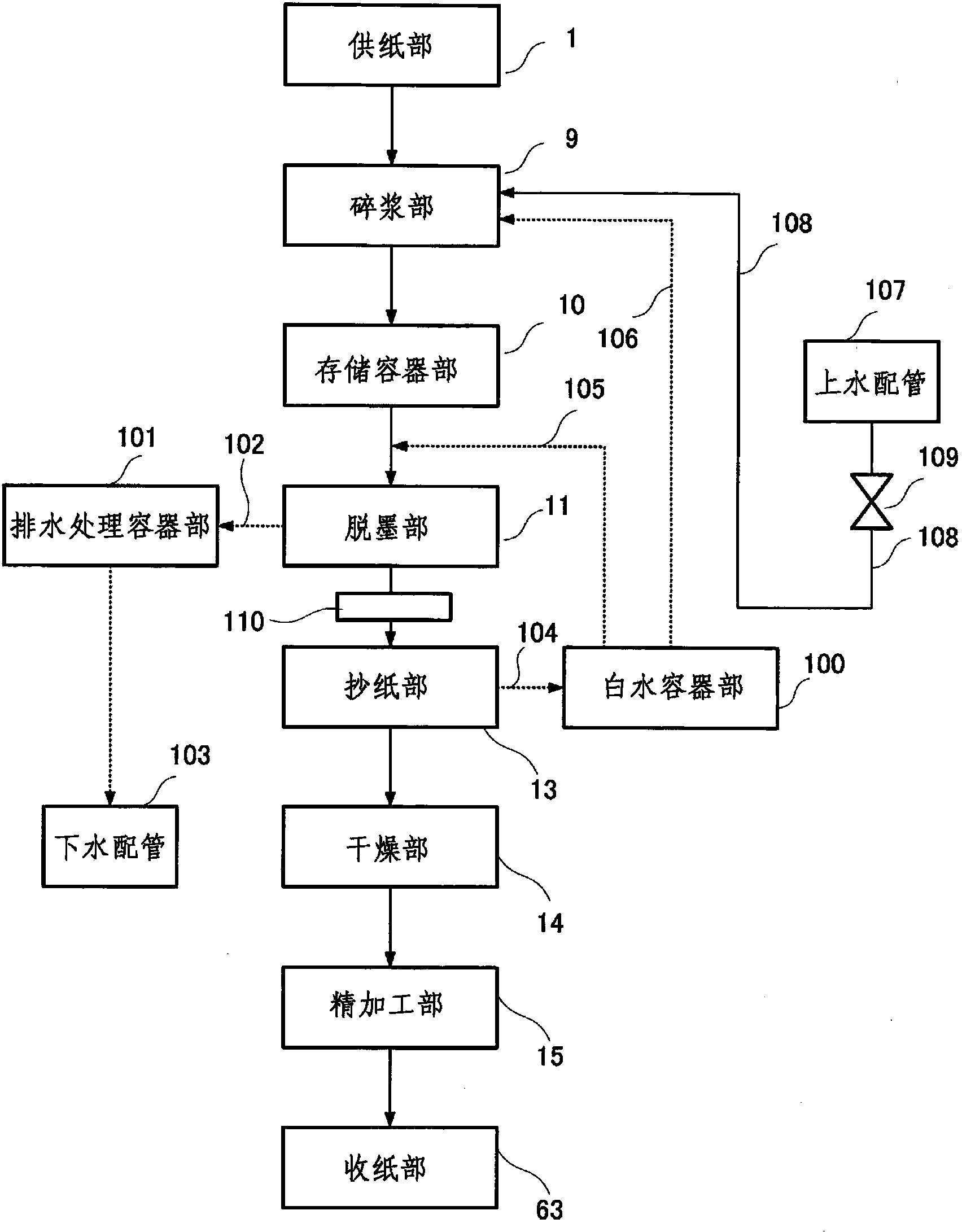

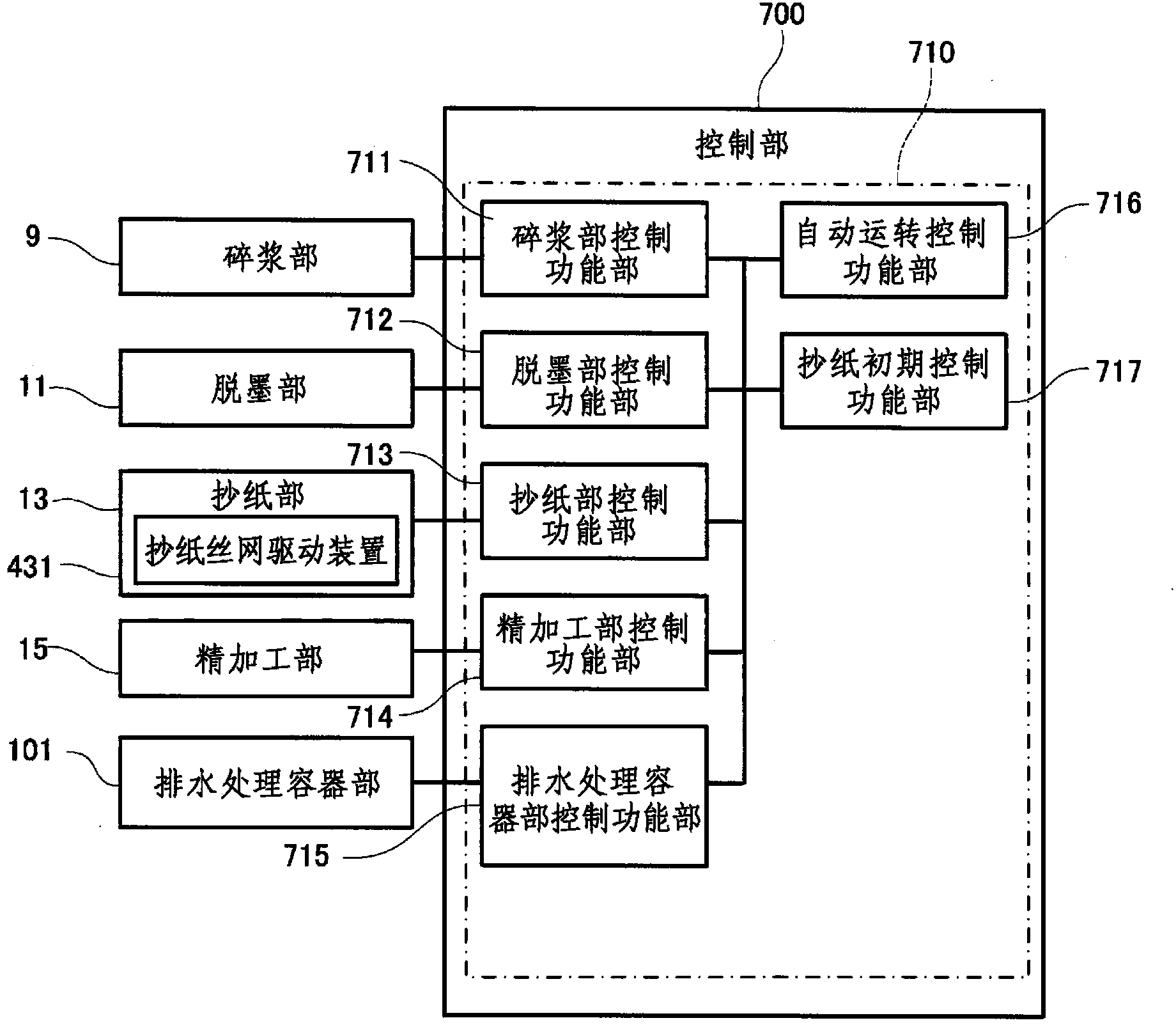

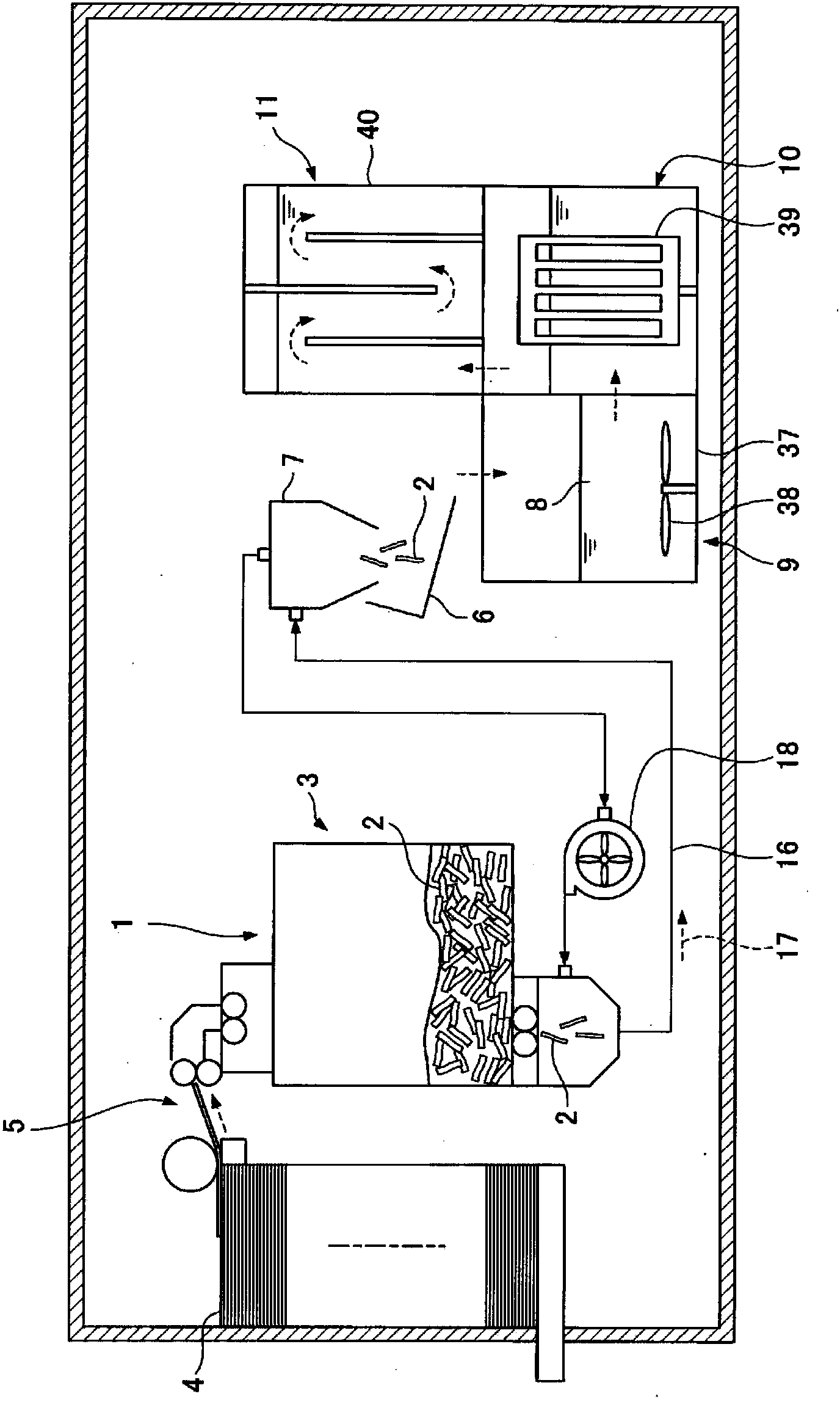

[0018] Hereinafter, embodiments of the present invention will be described based on the drawings. exist Figure 1 to Figure 4 Among them, the waste paper recycling processing device includes a plurality of processing units constituting a waste paper recycling processing system. The processing section includes a paper feeding section 1 , a pulping section 9 , a storage container section 10 , a deinking section 11 , a papermaking section 13 , a drying section 14 , a finishing section 15 , a white water container section 100 and a waste water treatment container section 101 . In addition, the waste paper recycling processing apparatus includes a control unit 700 that controls the operation of each processing unit.

[0019] The paper supply unit 1 supplies waste paper 4 as a recycled raw material, and includes: a storage unit 3 for storing paper scraps 2 obtained by finely cutting the waste paper 4; a paper supply device 5 for supplying the waste paper 4 to the storage unit 3; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com