Device for receiving and transmitting bar shaped goods

An article, rod-shaped technology, applied in applications, food science, tobacco, etc., can solve the problems of increased drum diameter, damage and shutdown and safety accidents, and cannot be increased indefinitely, to reduce operating speed, improve production efficiency, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

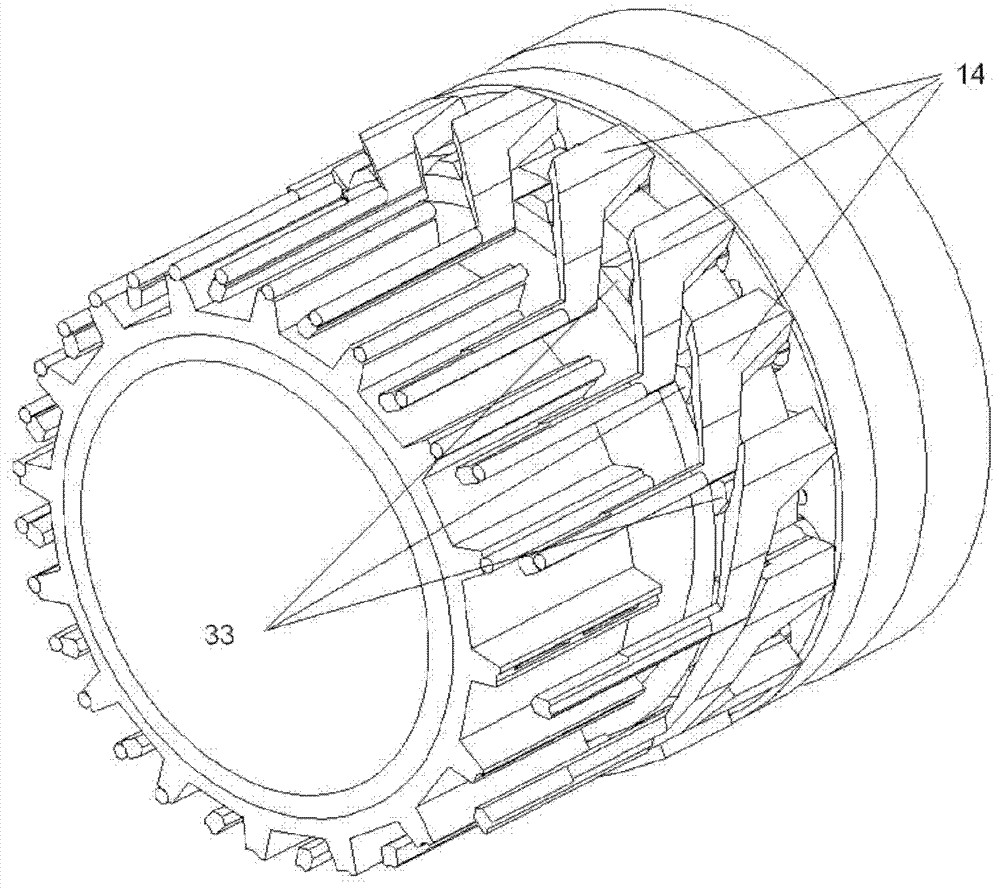

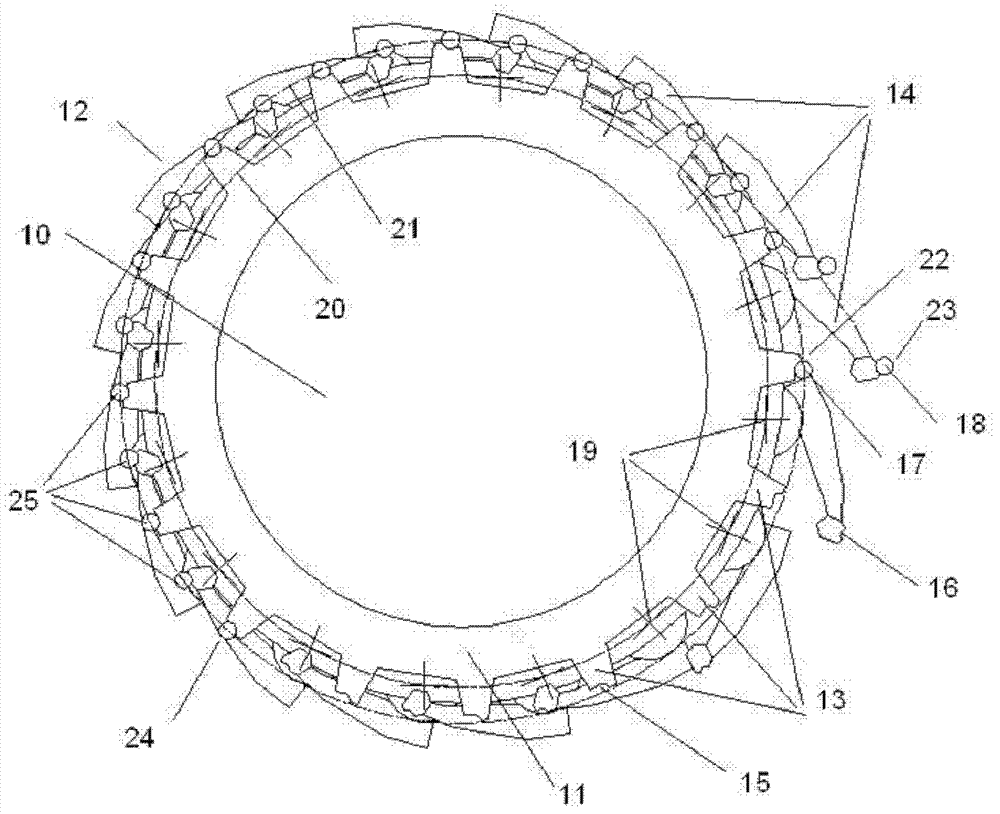

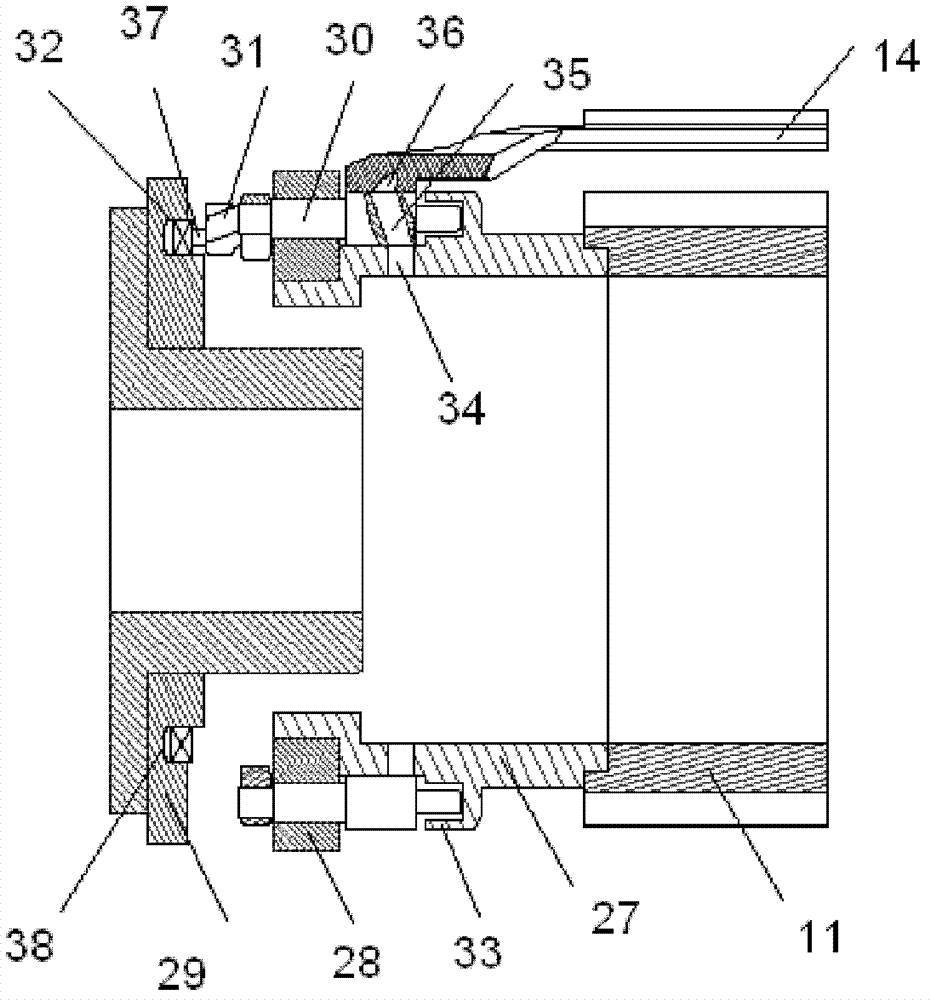

[0044] Such as Figure 1 to Figure 3 As shown, the present invention is used for the device 10 of receiving and transmitting rod-shaped articles, comprises two independent receiving parts 11 and 12, and the first receiving part 11 and the second receiving part 12 are coaxial and arranged crosswise; The first receiving part 11 For receiving the front row items 17 from the vertical conveyor, the second receiving part 12 is used to receive the rear row items 18 from the longitudinal conveyor; the first receiving part 11 and the second receiving part 12 receive the front row items 17 at the same time and the rear row of items 18, and receive the front row of items 17 and the rear row of items 18 on the same circumference 21;

[0045] The first receiving part 11 is a rotating body, and the circumferential direction of the first receiving part 11 is evenly distributed with a plurality of fixed smoke receiving claws 13 at equal intervals; the movable end of each fixed smoke receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com