Tool setting device and method for double-head counter-pressure progressive forming

A technology of incremental forming and tool setting device, applied in the direction of angle/taper measurement, etc., can solve the problem of difficult tool setting, and achieve the effect of rapid tool setting and improvement of progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

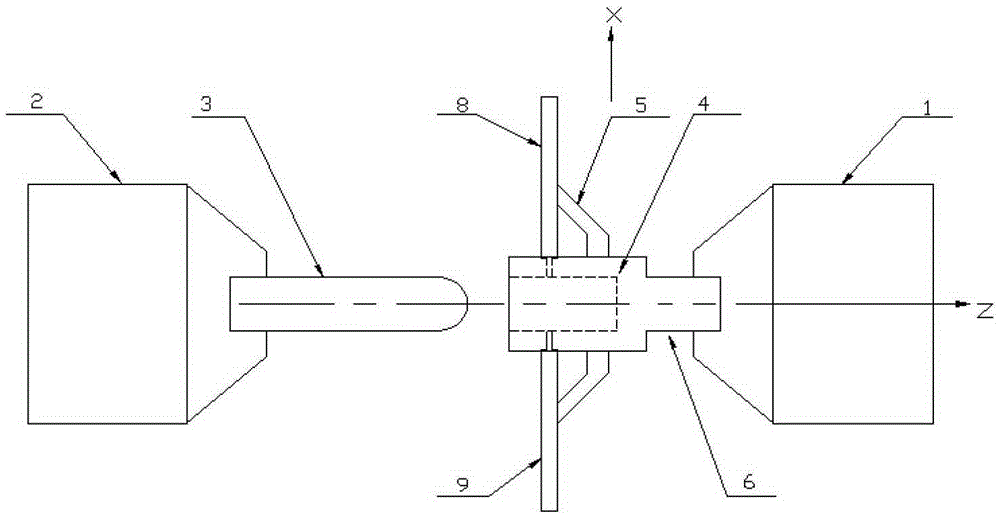

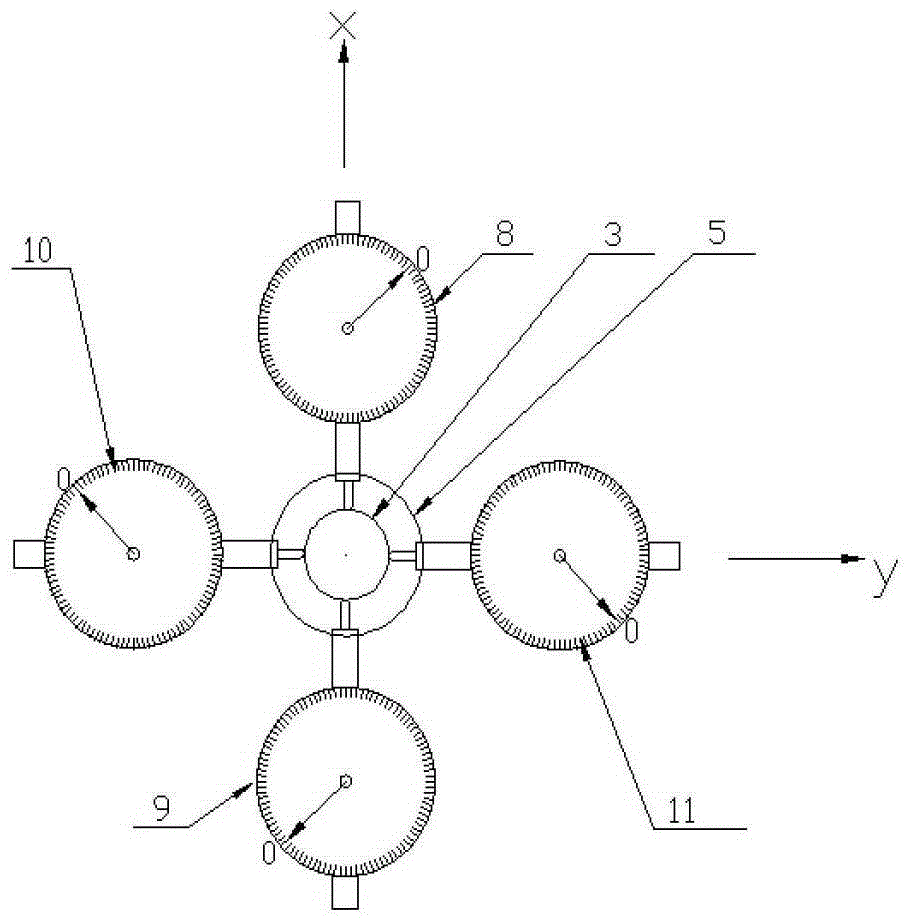

[0020] Such as Figure 1~3 As shown in the figure, a tool setting device for double-head counter-pressure progressive forming, including a table seat, a main indenter side tool handle 1, an auxiliary indenter side tool handle 2, an auxiliary indenter 3, a reference block 7, and four dial gauges Meter head: meter head a8, meter head b9, meter head c10, meter head d11, the meter base includes a reference hole 4, a meter frame 5 and a clamping column 6, and the clamping column 6 is located at the end of the meter base, And clamped at the end of the handle 1 on the side of the main pressure head, the table frame 5 is fixed on the clamping column 6, and the center axis of the reference hole 4 of the table base is in the The axes are coincident, and the four dial indicator heads are arranged in pairs on the meter frame 5. The meter frame 5 includes a bracket arranged in the shape of a "ten", and the four dial indicator heads are paired in pairs. Placed on a "ten"-shaped bracket, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com