Positioning and mold parting hydraulic cylinder sleeved combination type installing structure of corrugated pipe hydraulic molding machine

A technology of installation structure and hydraulic cylinder, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of corrugated pipe forming machine with huge structure and large installation space of mold frame, and achieve the effect of compact structure and reduced installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

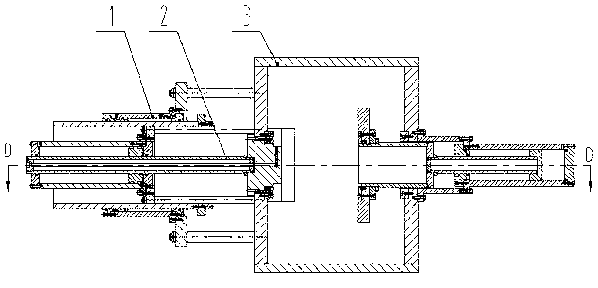

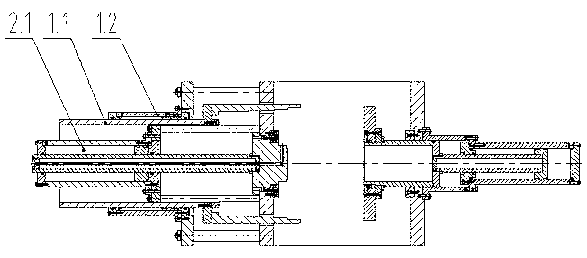

[0011] The bellows hydroforming machine positioning and splitting hydraulic cylinder nested installation structure shown in the accompanying drawings includes the positioning hydraulic cylinder 2.1 for the positioning mechanism 2 and the splitting hydraulic cylinder 1.2 of the splitting mechanism 1, the positioning hydraulic cylinder 2.1 and the splitting hydraulic cylinder. The mold hydraulic cylinder 1.2 is installed on the same side of the mold frame 3; the piston 1.1 of the mold split hydraulic cylinder 1.2 is provided with an axial through hole, and the mold split hydraulic cylinder 1.2 is set on the positioning hydraulic cylinder 2.1 through the axial through hole on the piston 1.1. In this embodiment, the central axes of the mold splitting hydraulic cylinder 1.2 and the positioning hydraulic cylinder 2.1 are coaxial.

[0012]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com