Shock insulation rubber support

A vibration isolation rubber and rubber pad technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of inability to achieve reset, insignificant energy consumption effect, long reset period, etc., and achieve good reset ability and auxiliary energy consumption performance. , Factory production is simple, to avoid the effect of difficult reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a further description of the technical content of the patent of the present invention, but it is not a limitation to the essential content of the patent of the present invention.

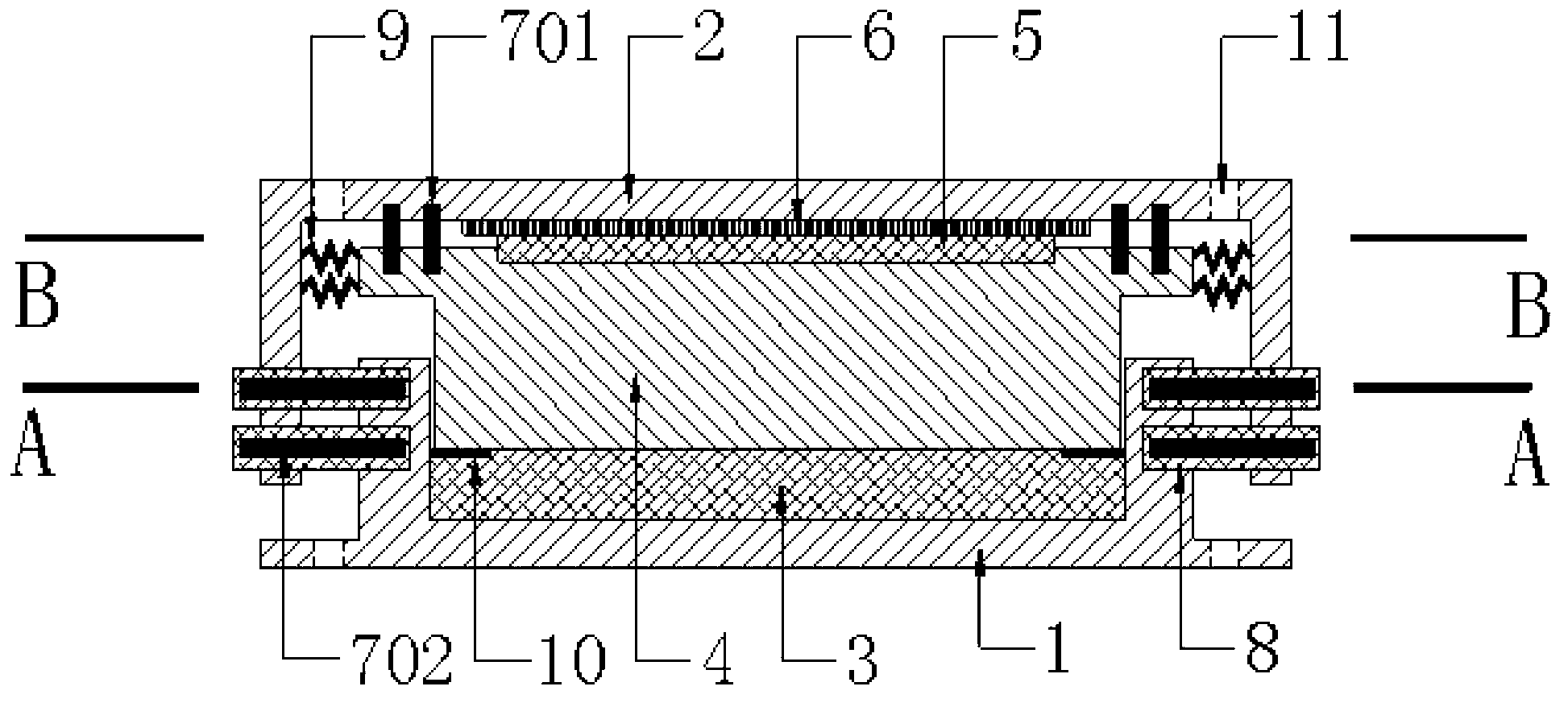

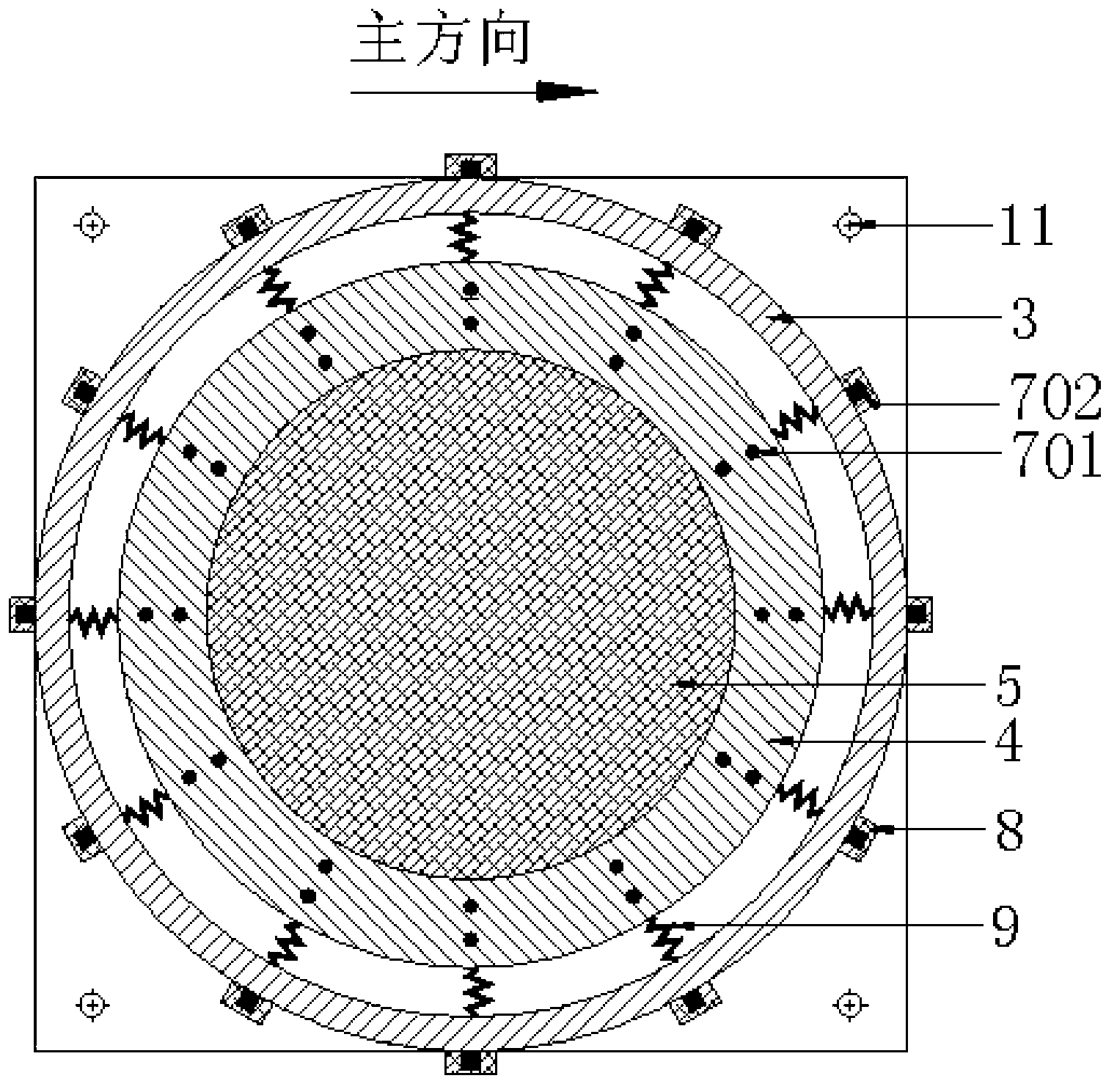

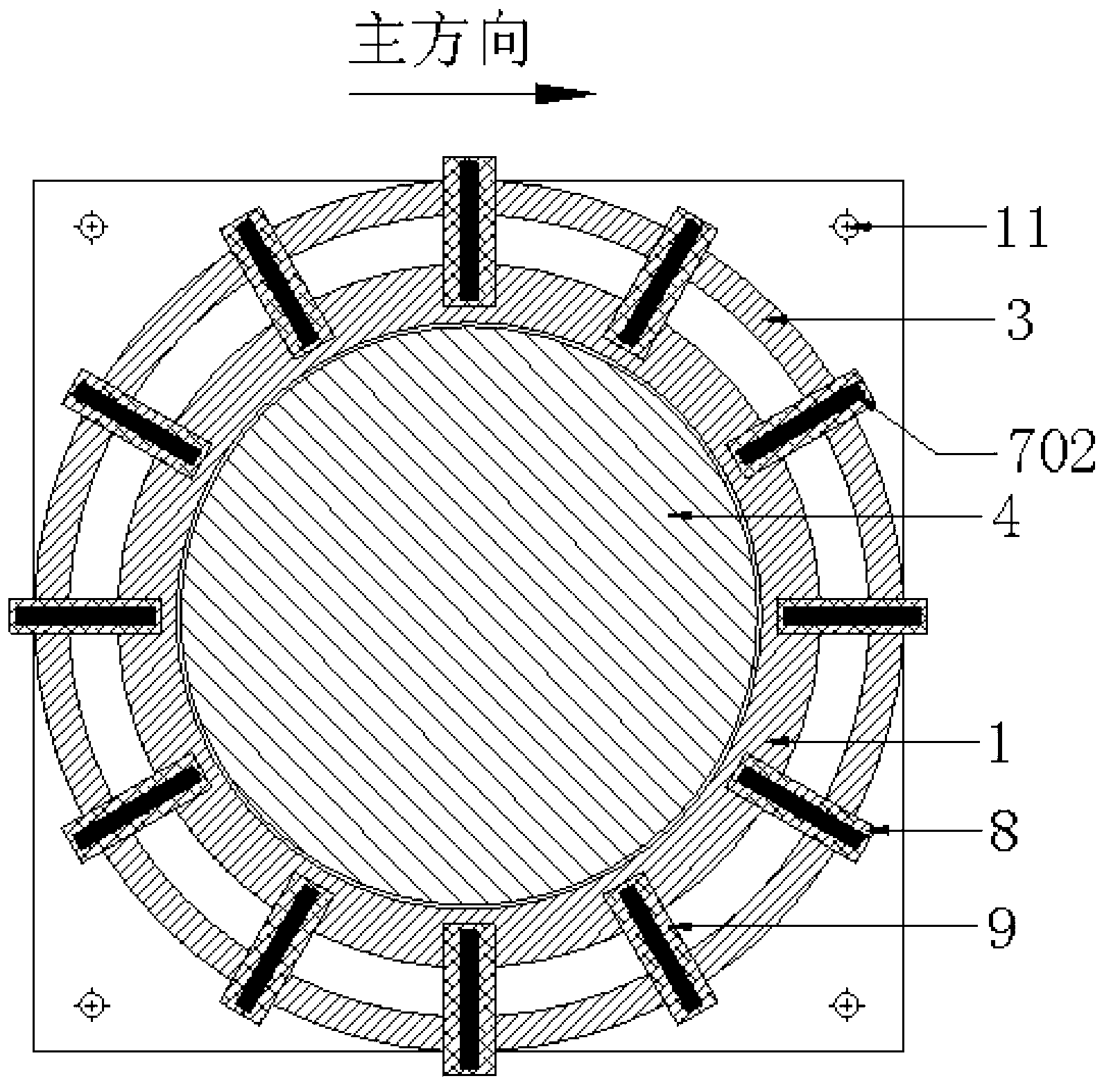

[0024] figure 1 It is a schematic diagram of a pot-type rubber bearing with tensile, shear energy consumption and self-resetting functions according to an embodiment of the present invention; figure 2 for figure 1 The cross-sectional view of A-A in the middle; image 3 for figure 1 The cross-sectional view of B-B in middle; figure 1 , 2 As shown in , 3, the basin-type shock-isolation rubber bearing with the functions of tensile resistance, shear energy consumption and self-resetting includes a bottom plate 1 and a top plate 2, and a rubber pad 3 and a middle steel liner are arranged between the bottom plate 1 and the top plate 2 4. Teflon plate 5 and stainless steel slide plate 6, bottom plate 1 and top plate 2 are connected by horizontal lead rod 702, top plate 2 and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com