Step chain tensioning structure of escalator

A technology for escalators and cascade chains, applied in escalators, transportation and packaging, etc., can solve problems such as the slack state of cascade chains, and achieve the effect of simple structure and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

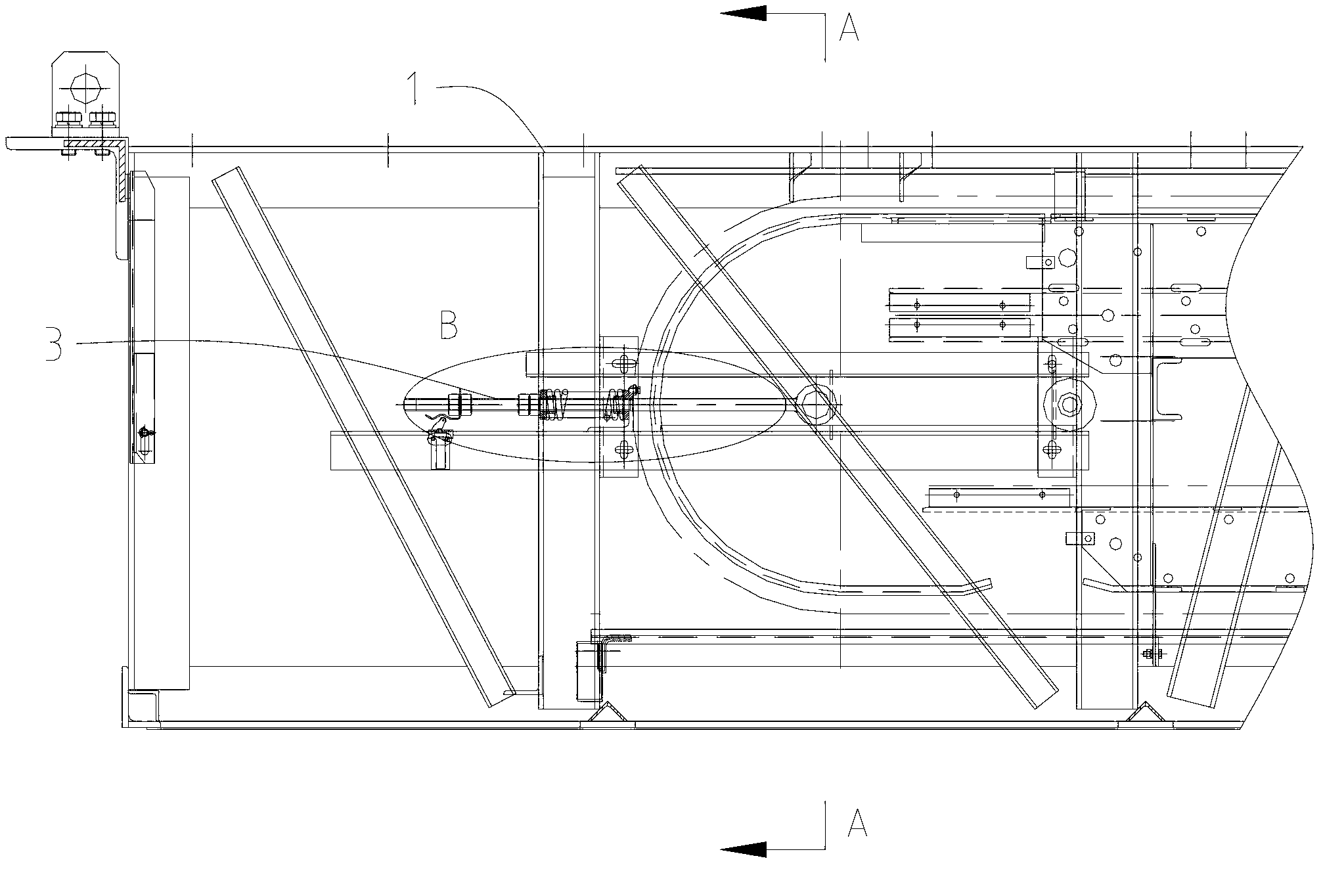

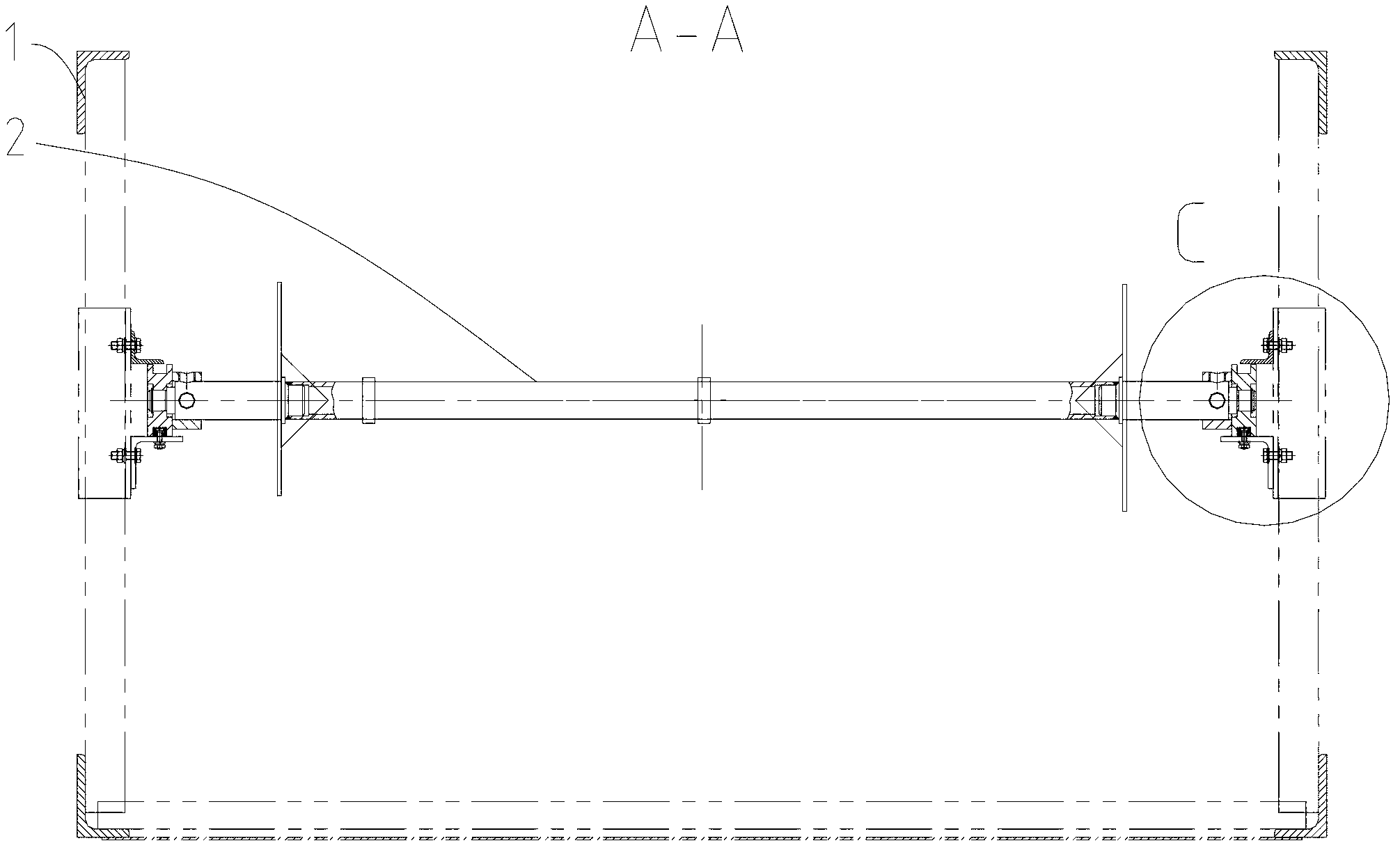

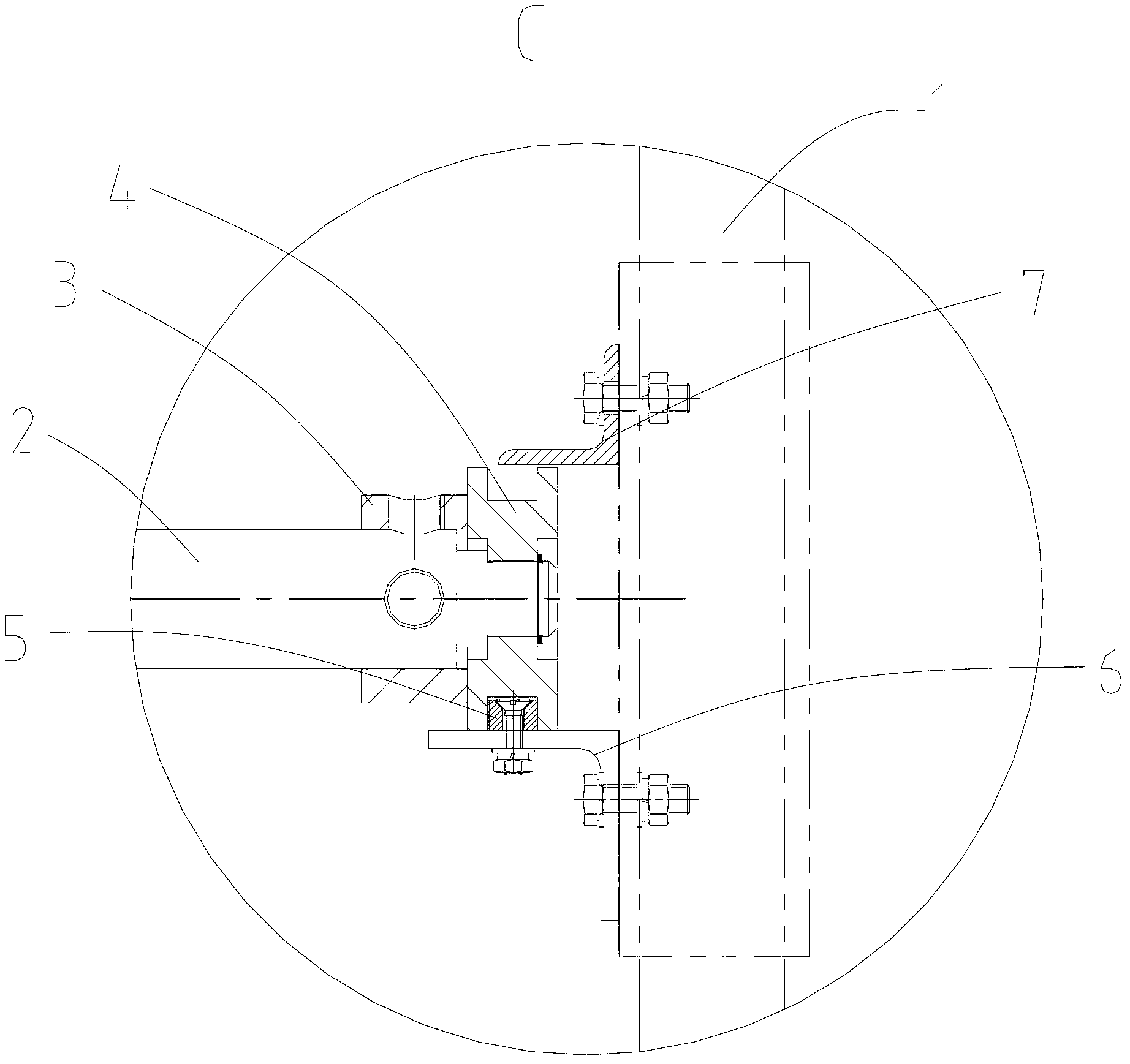

[0018] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] see Figure 1-4 Shown, a step chain tensioning structure of an escalator, including a tensioning shaft 2 extending along the width direction of the escalator, a sprocket mounted on the tensioning shaft 2, a tensioning rod fixed on the tensioning shaft 2 3. The elastic member 8 that is arranged between the tensioning rod 3 and the truss 1 and can provide the elastic recovery force of the tensioning rod 3, the switch 14 fixedly installed relative to the truss 1, is fixed on the tensioning rod 14 for touching the switch The switch baffle 13 of 14, the tension guide wheel 4 installed at both ends of the tension shaft 2, the slide rails 5 fixed on both sides of the truss 1 of the escalator and extending along the length direction of the escalator, the tension shaft The sprocket wheel on 2 is used for the rotation of the step chain, and the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com