PWHT (postweld heat treatment) device for mounting utility boiler water wall

A technology for post-weld heat treatment and power plant boilers, which is applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of increasing the difficulty of fixing and heater fixing, and achieves the effect of effective local heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

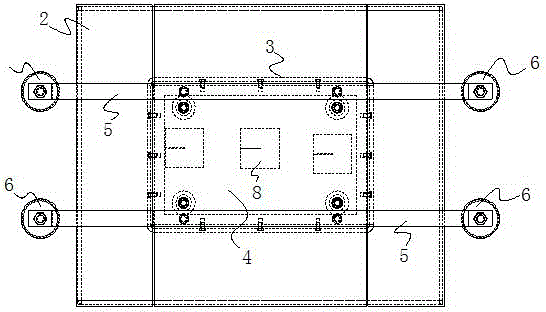

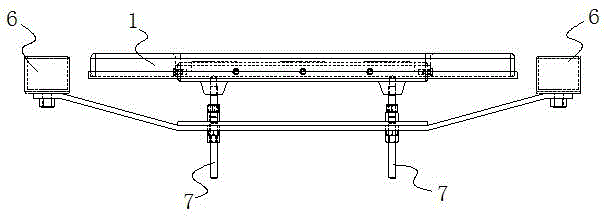

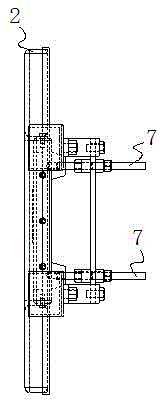

[0019] First, introduce the specific structure of the present invention. The present invention includes a thermal insulation cotton fixing plate 2 provided with thermal insulation cotton 1, a heating assembly arranged on the lower end surface of the thermal insulation cotton fixing plate 2, and a heating assembly arranged on the upper end surface of the thermal insulation cotton fixing plate 2 for The heating plate fixing plate 3 for fixing the heating assembly, and the adsorption component arranged on the heating plate fixing plate 3 for adjusting the adsorption strength of the device.

[0020] Considering that the water-cooled wall dissipates heat quickly during heat treatment, it not only causes waste of energy, but also causes excessive temperature gradient near the weld. Utilizing the good flexibility and heat insulation performance of thermal insulation cotton, it can be attached to the uneven surface of the water-cooled wall under the action of pressure. Therefore, this ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap