Ground rail vehicle for fully automatic cable partial discharge test

A cable partial discharge, fully automatic technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as limiting the stability and safety of cable reel diameter specifications, width margin, stability and safety, adjusting roller distance, and inability to meet, etc. To achieve the effect of stable center of gravity, safe operation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

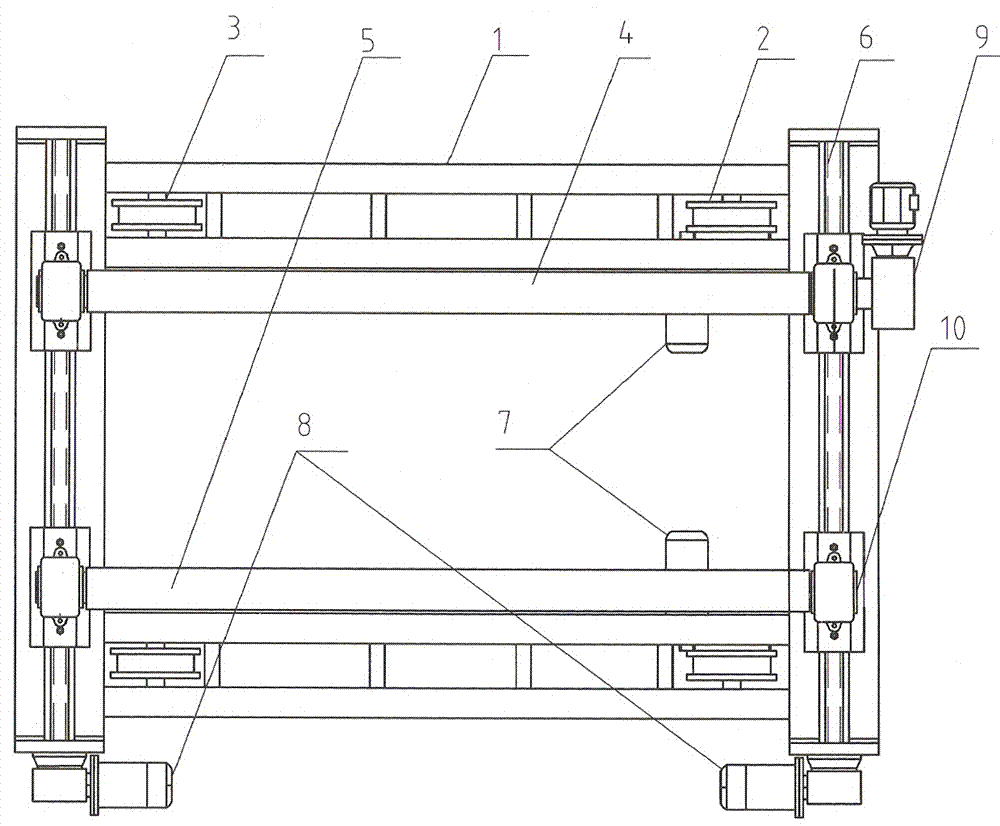

[0011] A ground rail vehicle for fully automatic cable partial discharge test, comprising a vehicle frame 1, on which are mounted rail wheels running on the bottom rail, on the vehicle frame are mounted two mutually parallel active rotation rollers 4 and passive rotation rollers 5, The front and rear ends of the active self-rotating roller and the passive self-rotating roller are respectively connected to the front and rear screw mandrels 6 through screw nuts 10, and the front and rear screw mandrels are positive and negative pitch-adjustable screw mandrels with opposite helical directions of the left and right parts, which are different from the active The screw nuts connected to the self-rotating roller and the passive self-rotating roller are respectively matched with the left and right parts of the front and rear screw mandrels; the active self-rotating roller and the passive self-rotating roller are simultaneously opened or retracted in parallel.

[0012] The front and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com