Ore sand storage tank capable of unloading quantitatively

A storage tank and ore sand technology, which is applied in the field of ore sand storage tanks and ore sand storage tanks for quantitative unloading, can solve the problems of inaccurate unloading, the influence of subsequent processes, and the inability to quantitatively control unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

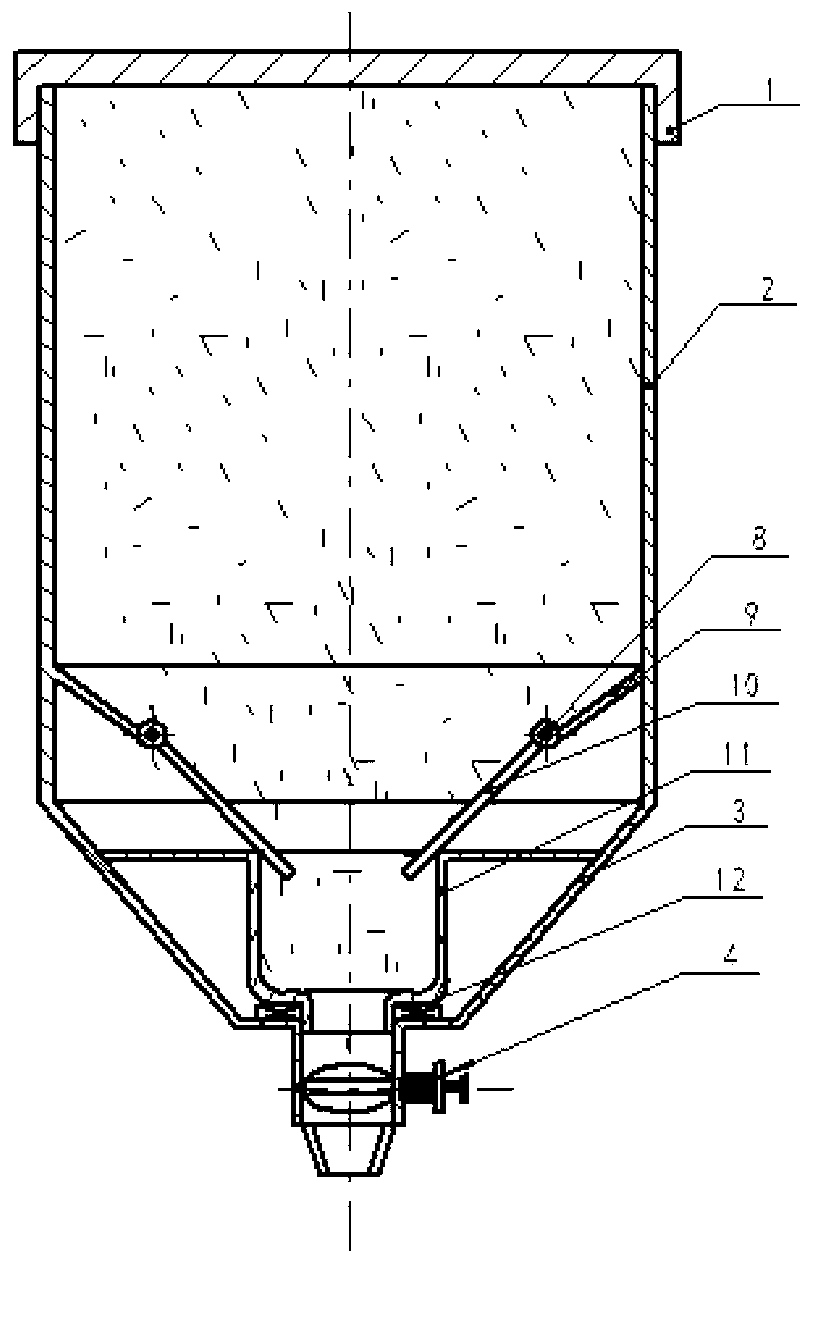

[0014] The following describes the embodiments of the present invention in detail with reference to the accompanying drawings. It should be noted that this embodiment is descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

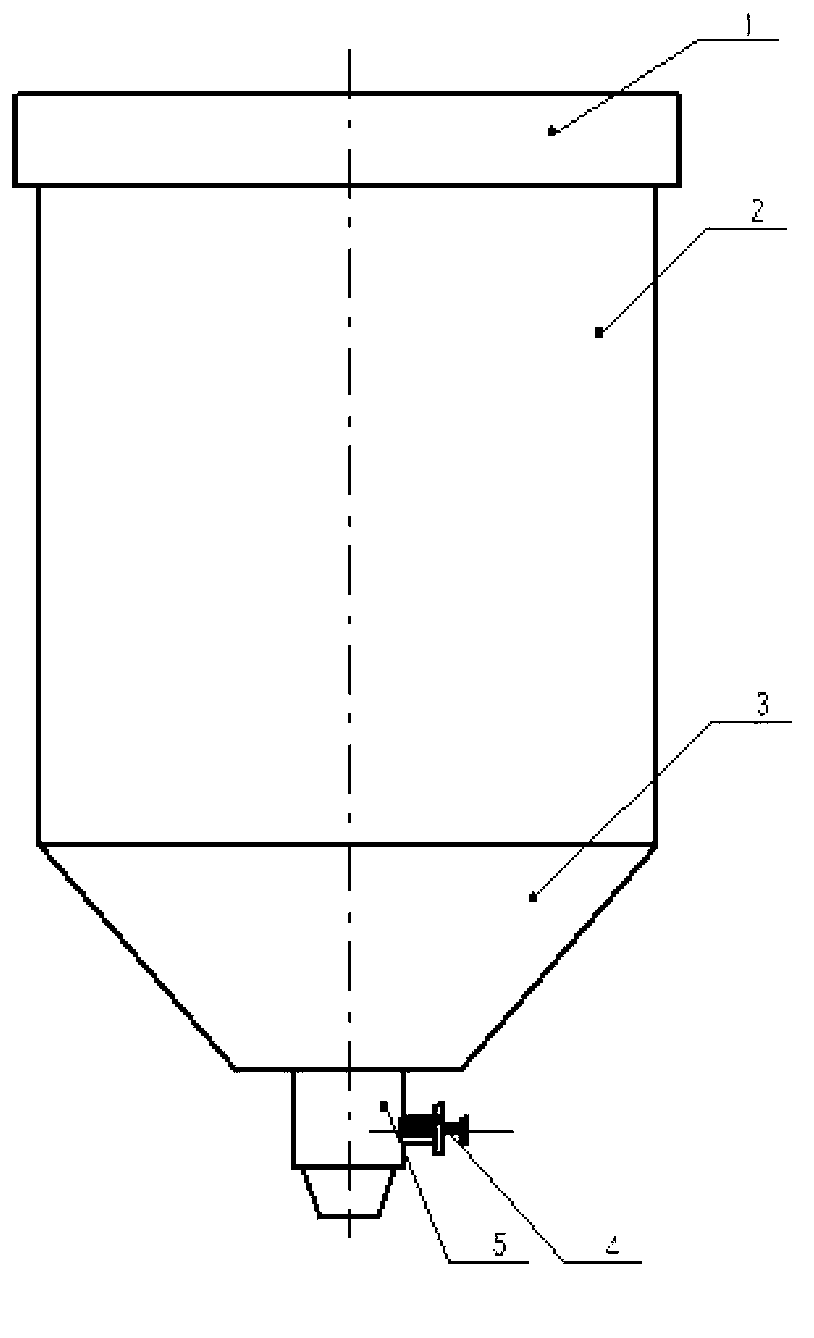

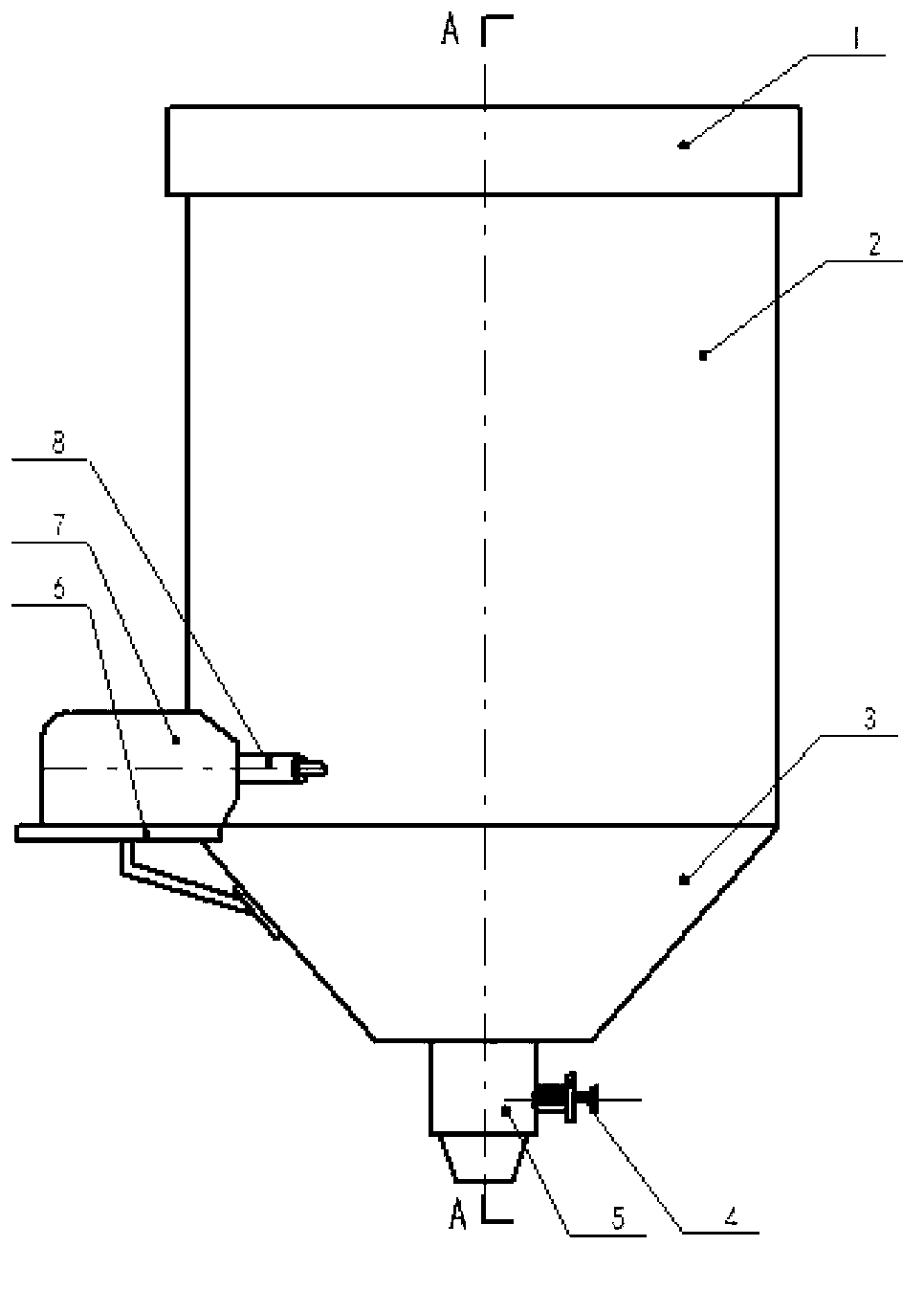

[0015] A quantitatively unloaded ore storage tank, comprising a tank body 2, a tank cover 1. The upper end of the tank body is coaxially covered with a tank cover, and a cone-shaped hopper 3 is coaxially formed in the lower part of the tank body. A discharge pipe 5 is installed coaxially at the end, a butterfly valve 4 is installed in the radial direction of the discharge pipe, and ore is contained in the tank body of the storage tank.

[0016] The innovation of the present invention lies in:

[0017] A tapered ring plate 9 is fixed radially in the lower part of the tank body of the storage tank, which can make the ore in the tank body not leave dead corners; the inner edge of the tapered ring plate is radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com