Adsorption material circulating moving type adsorption device for tail gas treatment

An adsorption material and tail gas treatment technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of insufficient adsorption of adsorption materials, large capital consumption, pollution, etc., and achieve high utilization rate of desorption steam and save steam The effect of high dosage and high desorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

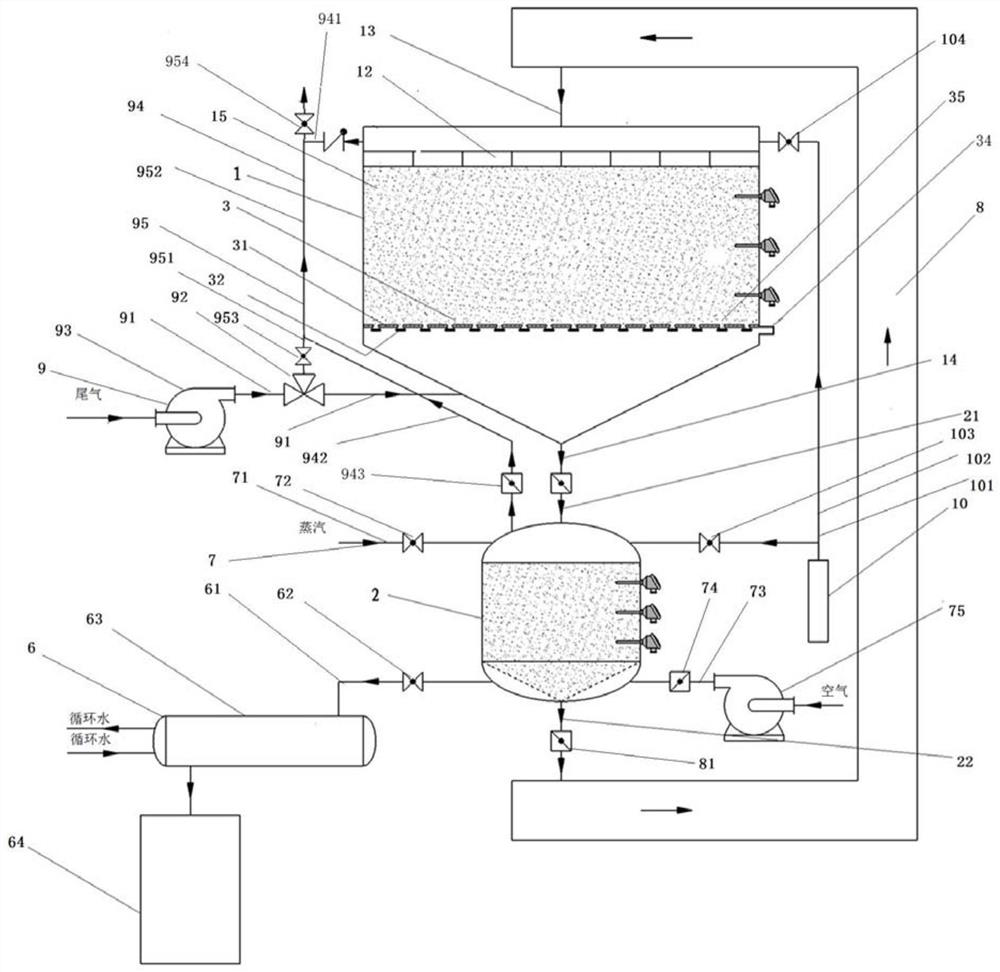

[0040] A circulating mobile adsorption device for adsorption materials for tail gas treatment, combined with figure 1 and Figure 13 As shown, it includes an adsorption tank 1 , a desorption tank 2 , an adsorption material delivery device 8 after desorption, a leveling device 12 and a discharge device 3 .

[0041] The adsorption tank 1 is filled with an adsorption material 15 for adsorption treatment of exhaust gas. The top of the adsorption tank 1 is provided with an adsorption tank feed pipe 13 , and the bottom end of the adsorption tank 1 is provided with an adsorption tank discharge pipe 14 .

[0042] The desorption tank 2 is used for receiving the adsorbed adsorption material 15 discharged from the adsorption tank 1 and performing desorption treatment on the adsorbed adsorption material 15 . The top of the desorption tank 2 is provided with a desorption tank feed pipe 21 , and the bottom end of the desorption tank 2 is provided with a desorption tank discharge pipe 22 . ...

Embodiment 2

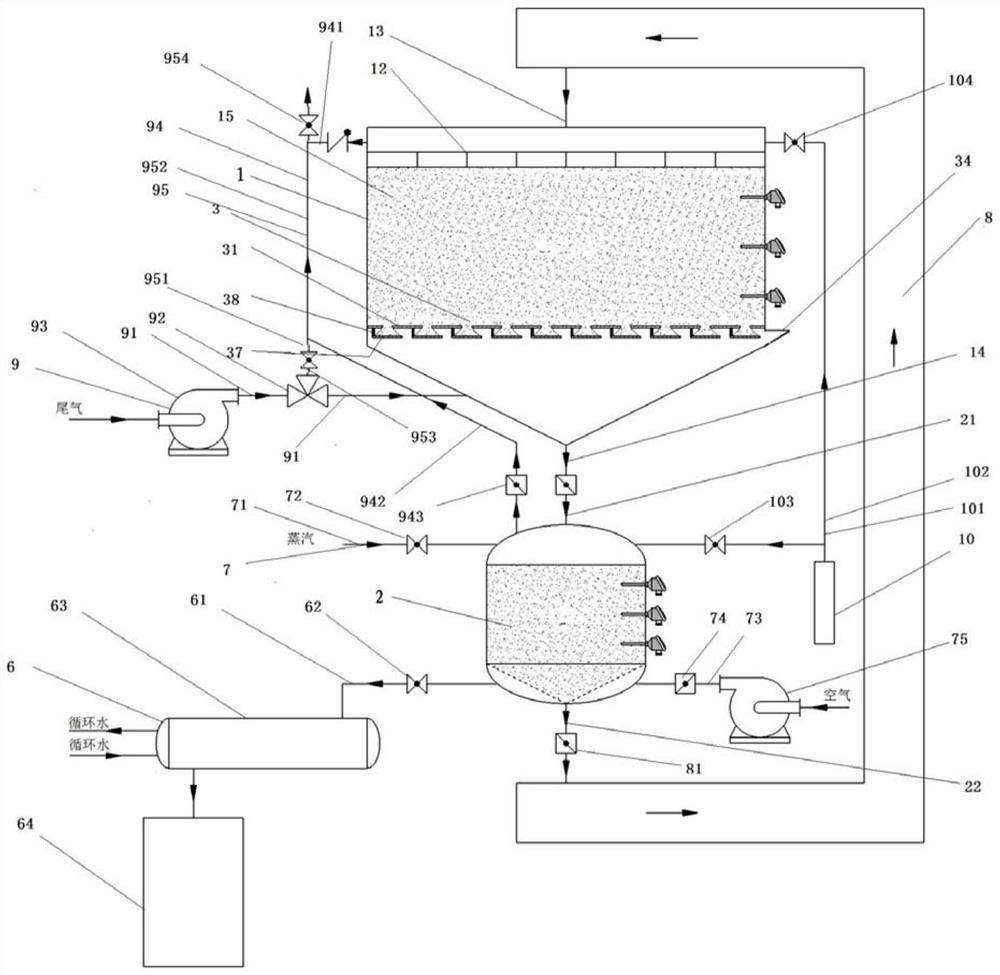

[0069] Based on the basis of embodiment 1, the difference between this embodiment and embodiment 1 is that the structure of the unloading device 3 changes, combining figure 2 and Figure 14 shown. That is, the unloading device 3 includes an upper grate 31, a chute 33, a lower grate 37, a movable scraper 38 and a scraper pushing mechanism 39.

[0070] The upper grate 31 is arranged inside the adsorption tank 1 for shielding the adsorption material 15 . A chute 33 for the sliding of the movable scraper 38 is provided on the left and right inner side walls of the adsorption tank 1 following the moving direction of the movable scraper 38, and the movable scraper 38 is driven by the scraper pushing mechanism 39 relative to the upper grate 31. The rectangular blanking opening of the suction tank moves to realize the accumulation and blanking operation of the adsorption material in the adsorption tank, and the scraper pushing mechanism 39 is fixedly arranged on the side wall of th...

Embodiment 3

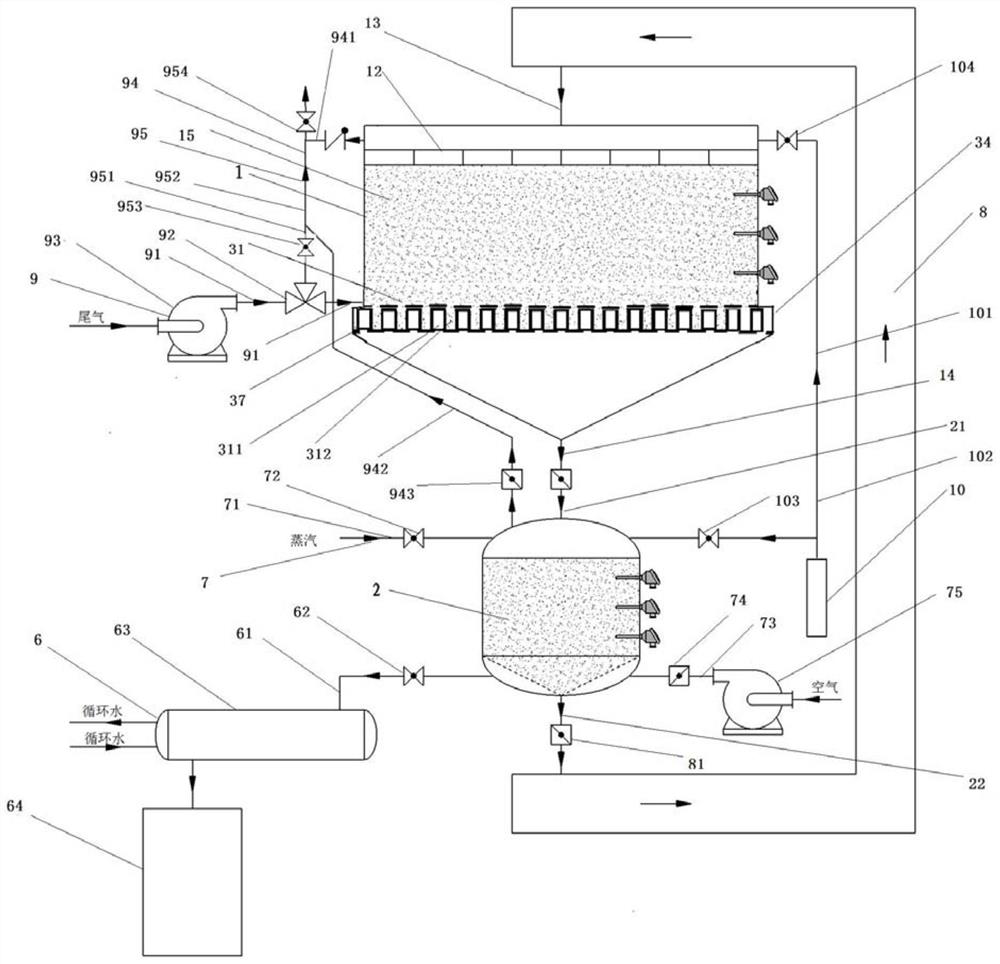

[0081] Based on the basis of embodiment 1, the difference between this embodiment and embodiment 1 is that the structure of the unloading device 3 changes, combining image 3 and Figure 15 shown. That is, the unloading device 3 includes an upper grate 31 and a lower grate 37, and the upper grate 31 and the lower grate 37 are fixedly arranged inside the adsorption tank 1 in parallel up and down, and are used to shield the adsorption material.

[0082] Conform to the movement direction of the movable material box 311 on the left and right side walls of the adsorption tank 1, respectively set up a chute 33 for the sliding of the material box pushing mechanism 313, and the movable material box 311 is driven by the material box pushing mechanism 313 relative to the upper grate 31 Move with the rectangular blanking opening of the lower grate 37 to realize the accumulation and blanking operation of the adsorption material in the feed bin, and the feed box pushing mechanism 313 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com